A method for preparing photonic crystals

A technology of photonic crystals and heating devices, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve the problems of low efficiency and high production cost, and achieve the effect of less process steps, low equipment requirements and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

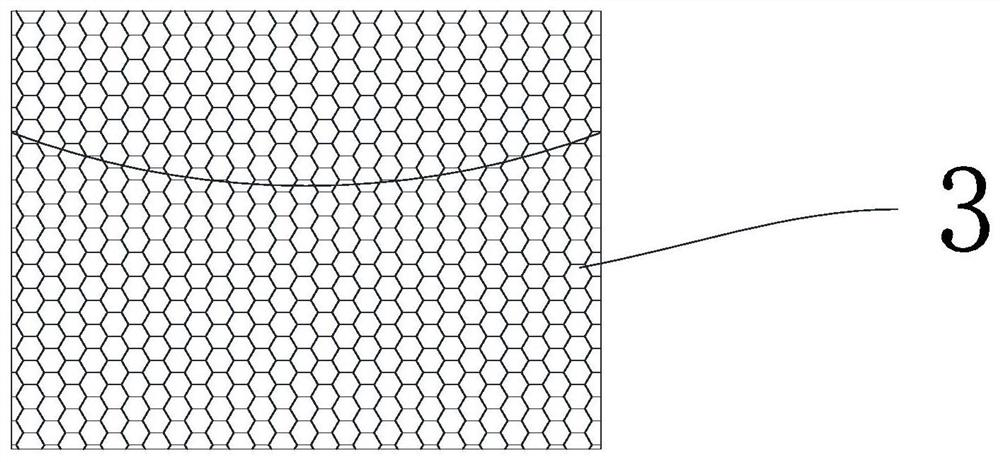

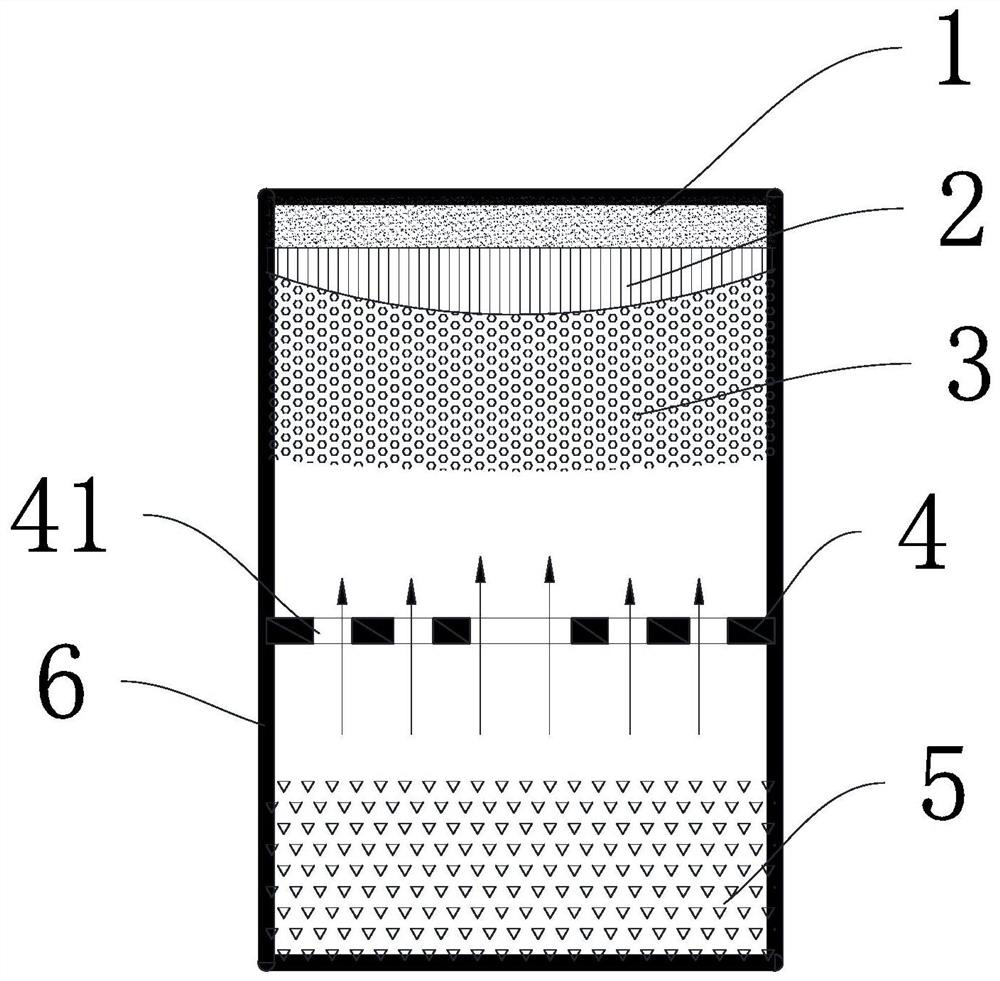

[0026] The invention provides a method for preparing photonic crystals. The preparation method comprises: in the heating device, from the bottom up, there are a pot bottom, a baffle plate with holes, a silicon carbide seed crystal and a radiator, and the heating device and the radiator are all made of graphite. production. The perforated baffle is a cylindrical perforated baffle, and at least two circles of through holes are arranged on the perforated baffle along the circumferential direction of the cylindrical baffle, and the diameter of each through hole is 6-40mm.

[0027] To heat the silicon carbide raw material placed in the bottom of the heating device, before the heating device is heated, the internal pressure is not greater than 10 Pa, and then argon gas is introduced, and after heating, the internal pressure of the heating device is maintained at 5kPa-80kPa. The heating temperature in the bottom of the heating device is 1900°C, and the heating time in the bottom of t...

Embodiment 2

[0029] The invention provides a method for preparing photonic crystals. The preparation method comprises: in the heating device, from the bottom up, there are a pot bottom, a baffle plate with holes, a silicon carbide seed crystal and a radiator, and the heating device and the radiator are all made of graphite. production. The perforated baffle is a cylindrical perforated baffle, and at least two circles of through holes are arranged on the perforated baffle along the circumferential direction of the cylindrical baffle, and the diameter of each through hole is 6-40mm.

[0030] Heat the silicon carbide raw material placed in the bottom of the heating device. Before the heating device is heated, make the internal pressure not greater than 10Pa, and then pass in argon gas. After heating, keep the internal pressure of the heating device at 50kPa. The heating temperature in the bottom of the heating device is 2000°C, and the heating time in the bottom of the pot is more than 20 hou...

Embodiment 3

[0032] The invention provides a method for preparing photonic crystals. The preparation method comprises: in the heating device, from the bottom up, there are a pot bottom, a baffle plate with holes, a silicon carbide seed crystal and a radiator, and the heating device and the radiator are all made of graphite. production. The perforated baffle is a cylindrical perforated baffle, and at least two circles of through holes are arranged on the perforated baffle along the circumferential direction of the cylindrical baffle, and the diameter of each through hole is 6-40mm.

[0033] Heat the silicon carbide raw material placed in the bottom of the heating device. Before the heating device is heated, the internal pressure is not greater than 10Pa, and then argon gas is introduced. After heating, the internal pressure of the heating device is maintained at 80kPa. The heating temperature in the bottom of the heating device is 2200°C, and the heating time in the bottom of the pot is mor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com