Preparation device and preparation method of dome cover window

A technology for preparing devices and windows, which is applied in chemical instruments and methods, self-melting liquid pulling method, single crystal growth, etc., can solve the problems of long processing cycle, affecting the shape and position accuracy and surface quality of the ball cover, and low yield. , to reduce processing costs, facilitate large-scale production, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] First, an apparatus for preparing a dome cover window according to the present disclosure will be described.

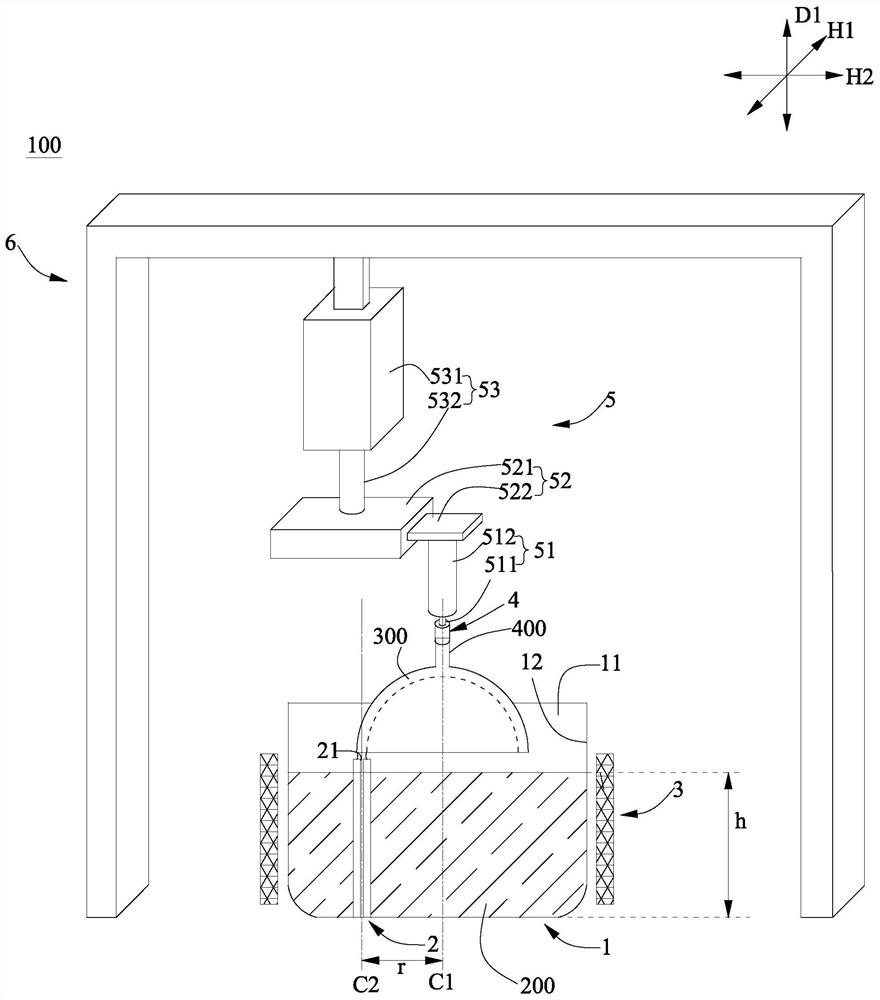

[0038] refer to Figure 1 to Figure 4 , the preparation device 100 of the spherical cover window includes a crucible 1 , a mold 2 , a heating mechanism 3 , a clamping mechanism 4 and a pulling mechanism 5 .

[0039] The crucible 1 has an inner chamber 11 . The inner cavity 11 is used to hold the raw material 200 for preparing the spherical cover window 300 , and the projection profile of the inner cavity 11 on the horizontal plane covers the circle formed by the outer diameter of the spherical cover window 300 to be prepared. In the design, in the projection view of the horizontal plane, the relationship between the projected contours between the dome cover window 300 and the crucible 1 can be conveniently determined on the projection of the horizontal plane.

[0040] In the example shown in the figures, the inner cavity 11 of the crucible 1 is cylindrical. ...

Embodiment 1

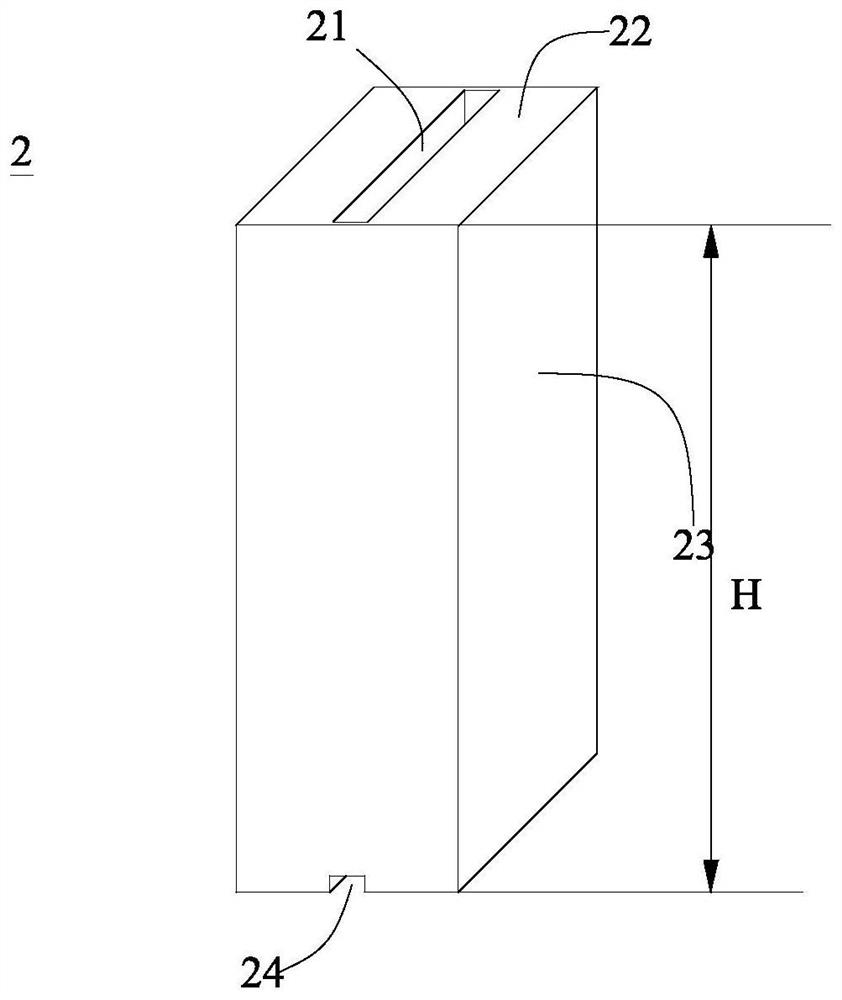

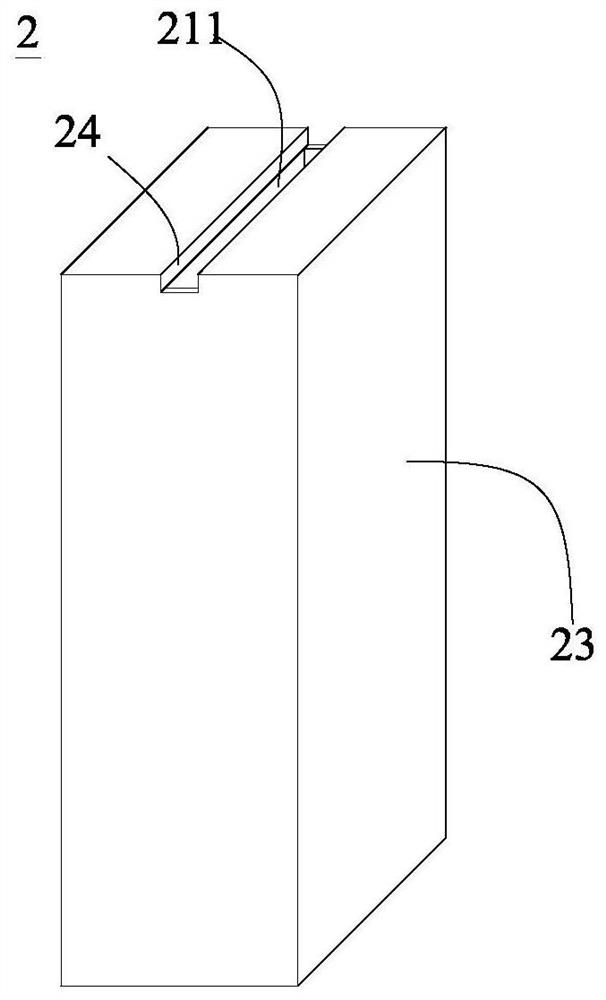

[0063] use Figure 1 to Figure 4 The preparation device 100 and the layout of the dome cover window.

[0064] Raw material 200 is germanium material, and the solid density ρ of germanium material s 5.33g / cm 3 , liquid density ρ l 5.51g / cm 3 The inner cavity 11 of crucible 1 is cylindrical, and the diameter of inner cavity 11 is 180mm, and crucible 1 adopts graphite material to make; Mold 2 is cuboid, and top surface 22 is a square, and the side length D of square is 8.7mm, and side 23 is Rectangle, the height H of rectangle is 110mm; Die 2 is contained in the position (that is r=45mm) that is 45mm from the center line C1 of crucible 11; Post-processing amount Δd=4mm, satisfying D=(d+Δd)×ρ s / ρ l , the outer radius of the spherical cover window 300 to be prepared is 45mm (i.e. r=45mm); 14kg of germanium raw material is put into the crucible 1, and the liquid level height of the raw material 200 is 100mm after the material is changed, that is, the height of the rectangle o...

Embodiment 2

[0068] use Figure 1 to Figure 4 The preparation device 100 and the layout of the dome cover window.

[0069] The raw material 200 is silicon material, and the solid density ρ of silicon material s 2.33g / cm 3 , liquid density ρl 2.53g / cm 3 The inner cavity 11 of crucible 1 is cylindrical, and the diameter of inner cavity 11 is 250mm, and crucible 1 adopts graphite material to make; Mold 2 is cuboid, and top surface 22 is a square, and the side length D of square is 12.9mm, and side 23 is Rectangle, the height H of rectangle is 100mm; Die 2 is contained in the position (being r=60mm) that is 60mm from the centerline C1 of crucible 11; Post-processing amount Δd=4mm, satisfying D=(d+Δd)×ρ s / ρ l , the outer radius of the dome window 300 to be prepared is 60 mm (i.e. r=60 mm); 10.9 kg of silicon raw material is put into the crucible 1, and the liquid level height of the raw material 200 after the chemical is 95 mm, that is, the rectangular shape of the side of the mold 2 The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com