Membrane and secondary battery

A diaphragm and anti-static technology, which is applied to battery components, separators/films/diaphragms/spacers, circuits, etc., can solve problems affecting the normal operation of the winding machine, diaphragm winding, and diaphragm wrinkling. Achieve good electrolyte diffusion performance, eliminate static electricity problems, and improve the effect of absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present application also relates to the preparation method of the lithium-ion battery diaphragm, at least including the following steps: adding binder, antistatic additive and ceramic material particles to an organic solvent to prepare a coating solution, and coating the coating solution on a substrate and then immersed in the coagulation solution to form a coated substrate, the thickness of the coating is 1-3 μm, and preferably 1.4-2.2 μm.

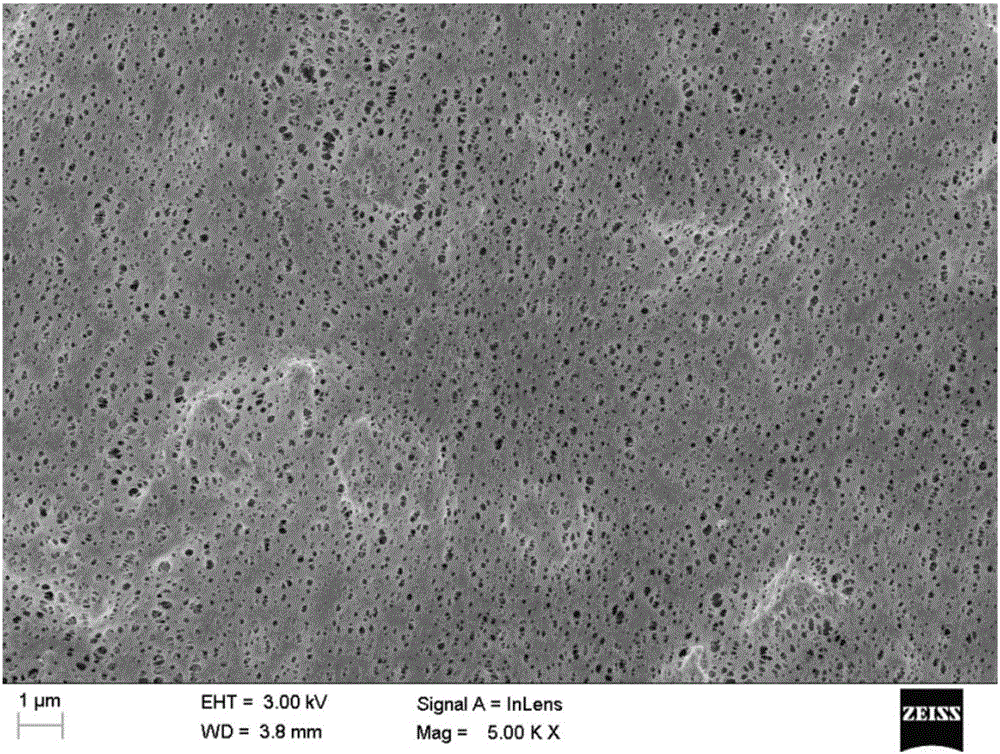

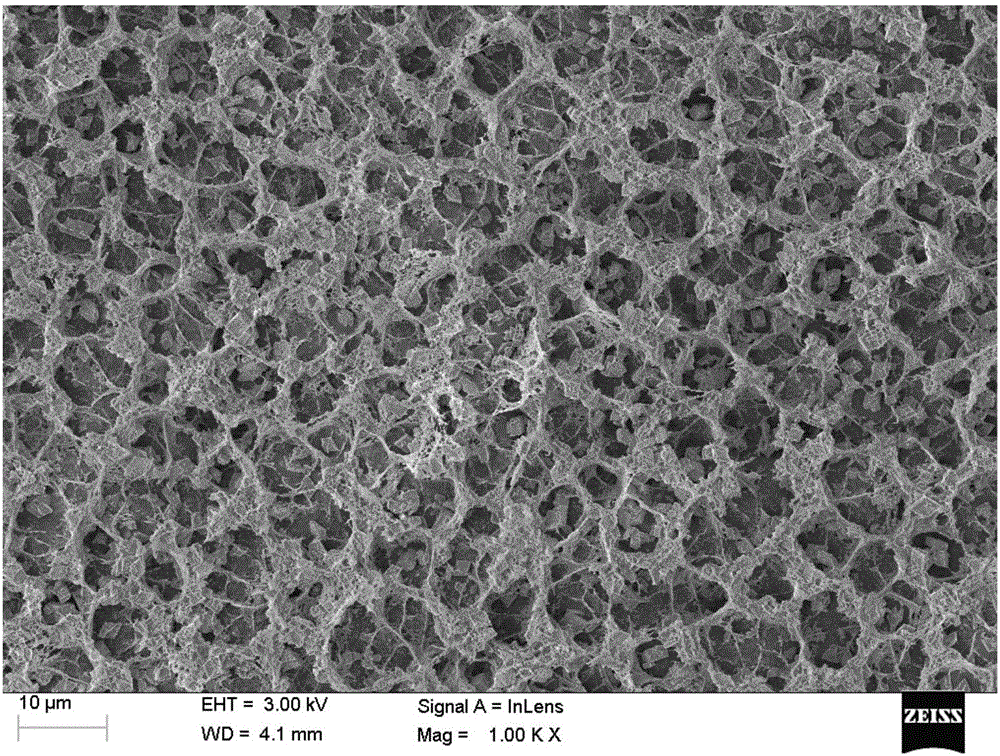

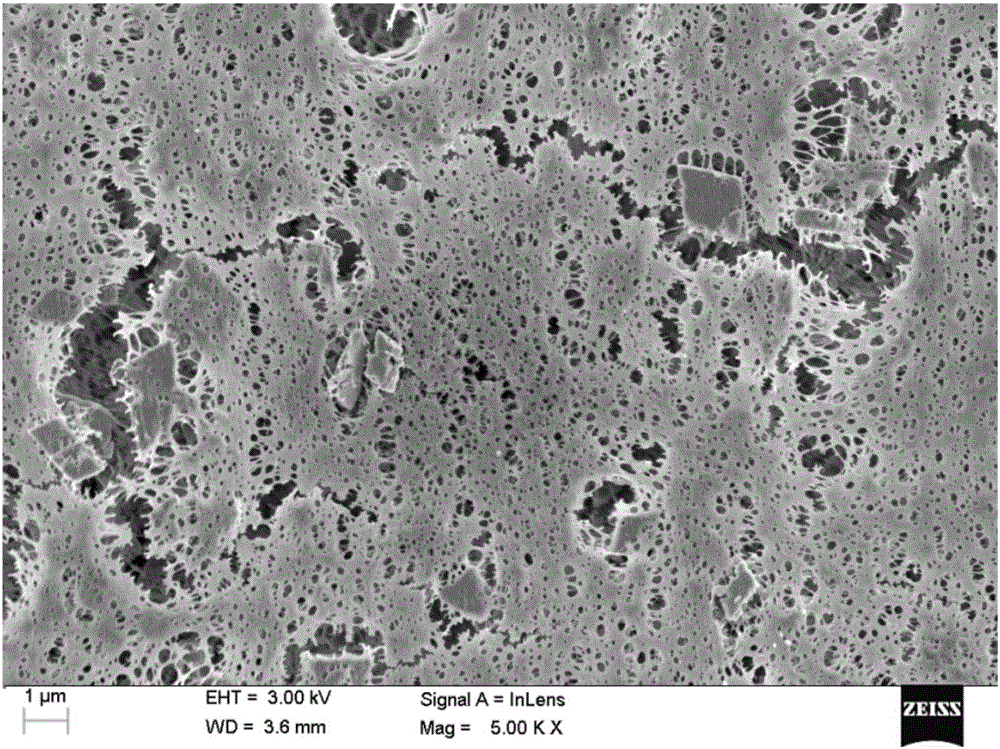

[0042] This application uses the principle of phase inversion method to prepare the coating of the diaphragm, wherein the coating liquid solvent used is oily, PVDF can be dissolved in the solvent; the coagulation liquid contains non-solvent, PVDF is insoluble in the non-solvent; and the solvent and the non-solvent are mutually soluble . After PVDF is dissolved in an oily solvent, it is mixed with ceramic material particles and antistatic additives to form a coating liquid. The coating solution is coated on the isolation membra...

Embodiment

[0049] 1. Using 2801 type PVDF produced by Arkema Company as a polymer, adding ceramic granular materials and antistatic additives, so that the solid content of the slurry is 18%, and preparing a coating liquid. The parameters of ceramic particle materials and antistatic additives are shown in Table 1;

[0050] Among them, the particle size of ceramic material particles is 2 μm, the particle size of Super P is 60 nm, the length of carbon nanotubes is 100 nm to 10 μm, and the diameter is 20 nm; the diameter of graphene is 3 μm to 60 μm, and the thickness is 0.6 μm to 4 μm;

[0051] 2. Coating the coating solution on a polyolefin porous substrate (produced by Toray, 12 μm thickness, 40% porosity, 250s / 100cc, TN12 for Gurley) with a scraper to form a coating wet film, the thickness of the coating is the same as that of ceramics The ratio of material particles is shown in Table 1;

[0052] 3. Immerse the coating liquid coating / porous substrate into the coagulation liquid containi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com