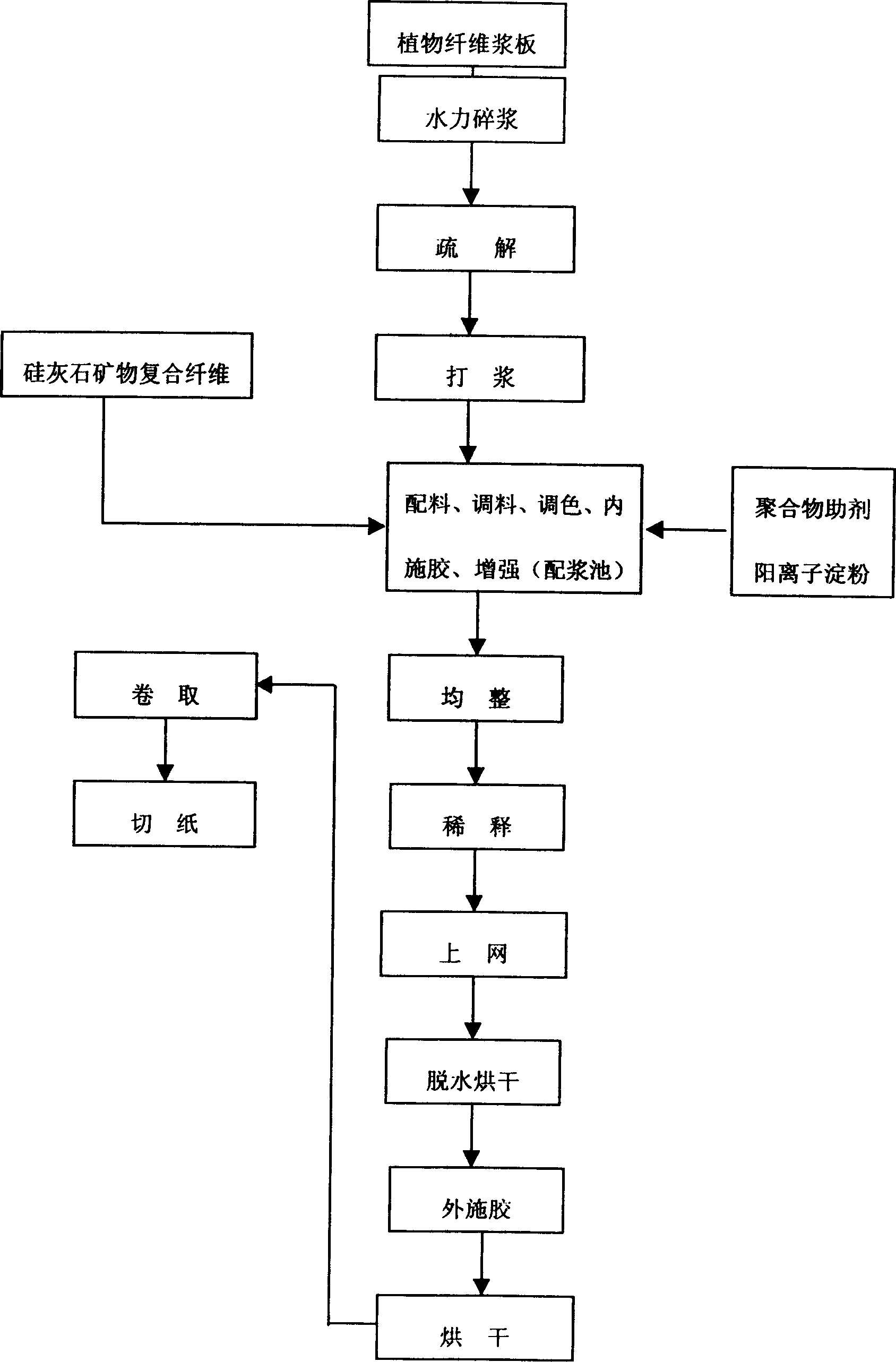

Modified wollastonite mineral composite fibre for making paper and its paper-making process

A composite fiber and mineral fiber technology, applied in textiles and papermaking, inorganic fiber/sheet, etc., can solve the problems of ecological environment deterioration, consumption of large wood resources, and restriction of paper industry development, etc., to eliminate static electricity, improve opacity and uniformity degree, the effect of protecting forest resources and ecological environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

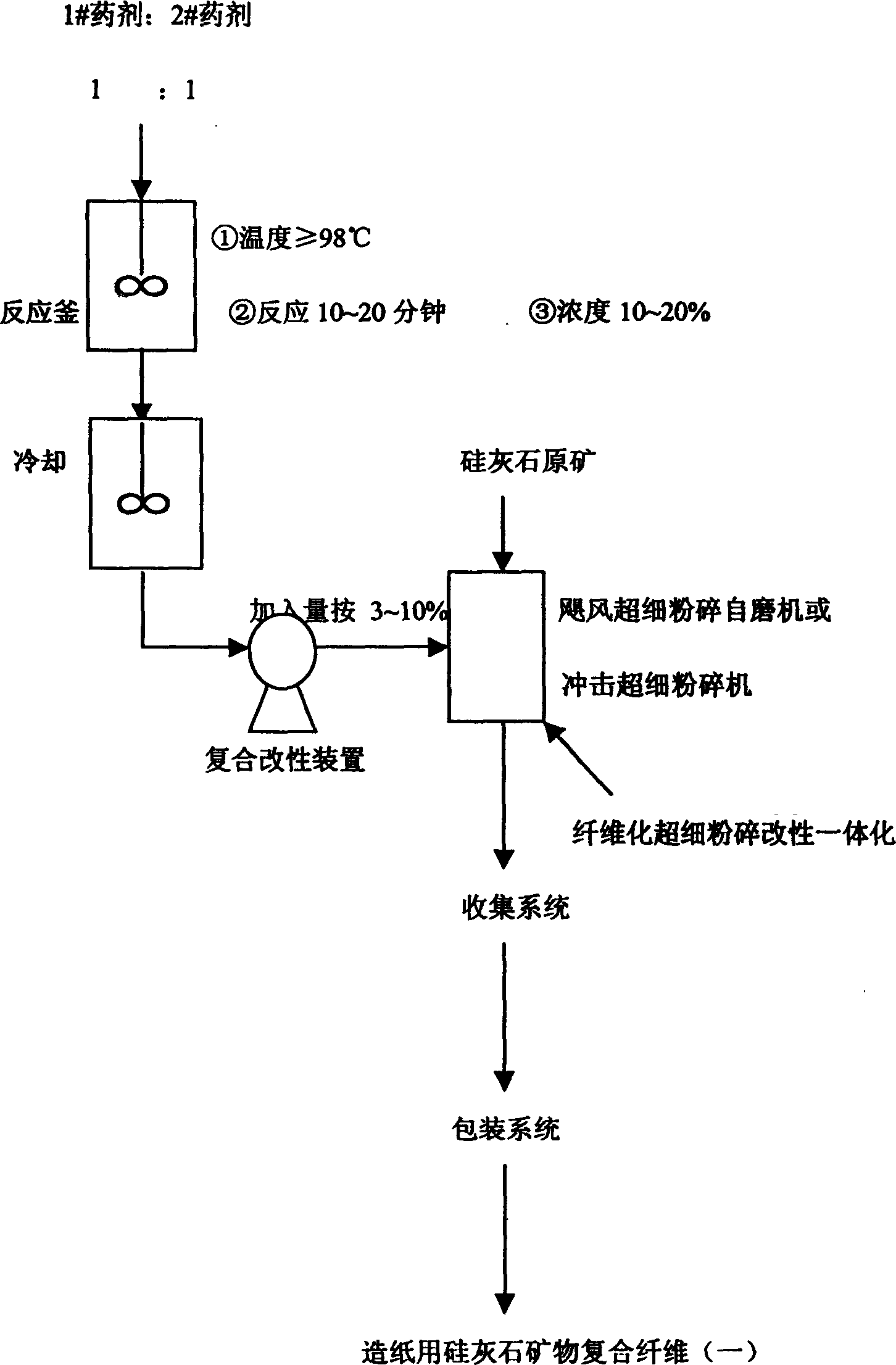

[0035] 1. Add aluminum sulfate for industrial use and sodium bicarbonate for industrial use into a reaction kettle with a stirrer in a ratio of 1:1, add water to dissolve and heat up to 98°C, react for 10 minutes, cool and make a compound with a concentration of 20%. Modifier Al;

[0036] 2. The wollastonite raw ore is crushed by a hurricane superfine self-grinding machine to a particle size of 5-20 μm, and the average diameter: length = 1: 6-30 elongated fibers. 3% Spray the above-mentioned composite modifier Al on the wollastonite mineral, so that the modifier Al coats the surface of the wollastonite mineral, and obtain the modified wollastonite mineral composite fiber a.

Embodiment 2

[0038] 1. Put industrial aluminum hydroxide and industrial sodium carbonate into a reaction kettle with agitator in a ratio of 1:1, add water to dissolve and heat up to 98°C, react for 20 minutes, cool and make a compound with a concentration of 10%. Modifier A2;

[0039] 2. Crushing the limestone raw ore with an impact ultra-fine pulverizer to a particle size of 5-20 μm, average diameter: length = 1: 6-30 elongated fibers, and the above-mentioned compound modified by 10% of the wollastonite mineral fiber weight The modifier A2 is sprayed on the wollastonite mineral fiber, so that the modifying agent A2 is coated on the surface of the wollastonite mineral fiber, and the modified wollastonite mineral composite fiber b is obtained.

Embodiment 3

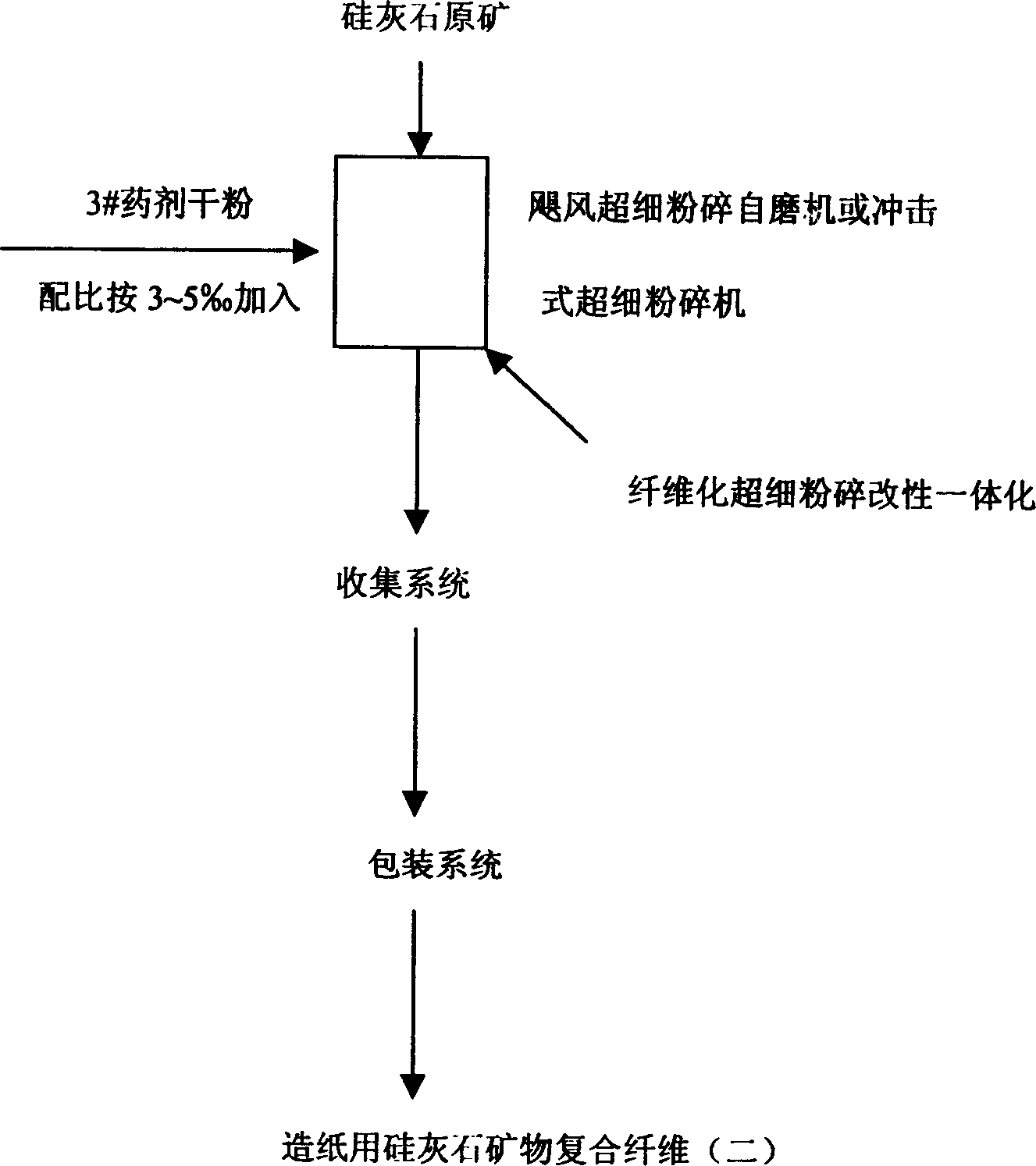

[0041] Crushing wollastonite raw ore into elongated fibers with a particle size of 5-20 μm and average diameter: length = 1:6-30, and adding modifier B, namely aluminum trichloride, according to 3‰ of wollastonite mineral weight, And make it coated on the surface of wollastonite mineral to obtain the modified wollastonite mineral composite fiber c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com