Substrate processing apparatus and substrate processing method

- Summary

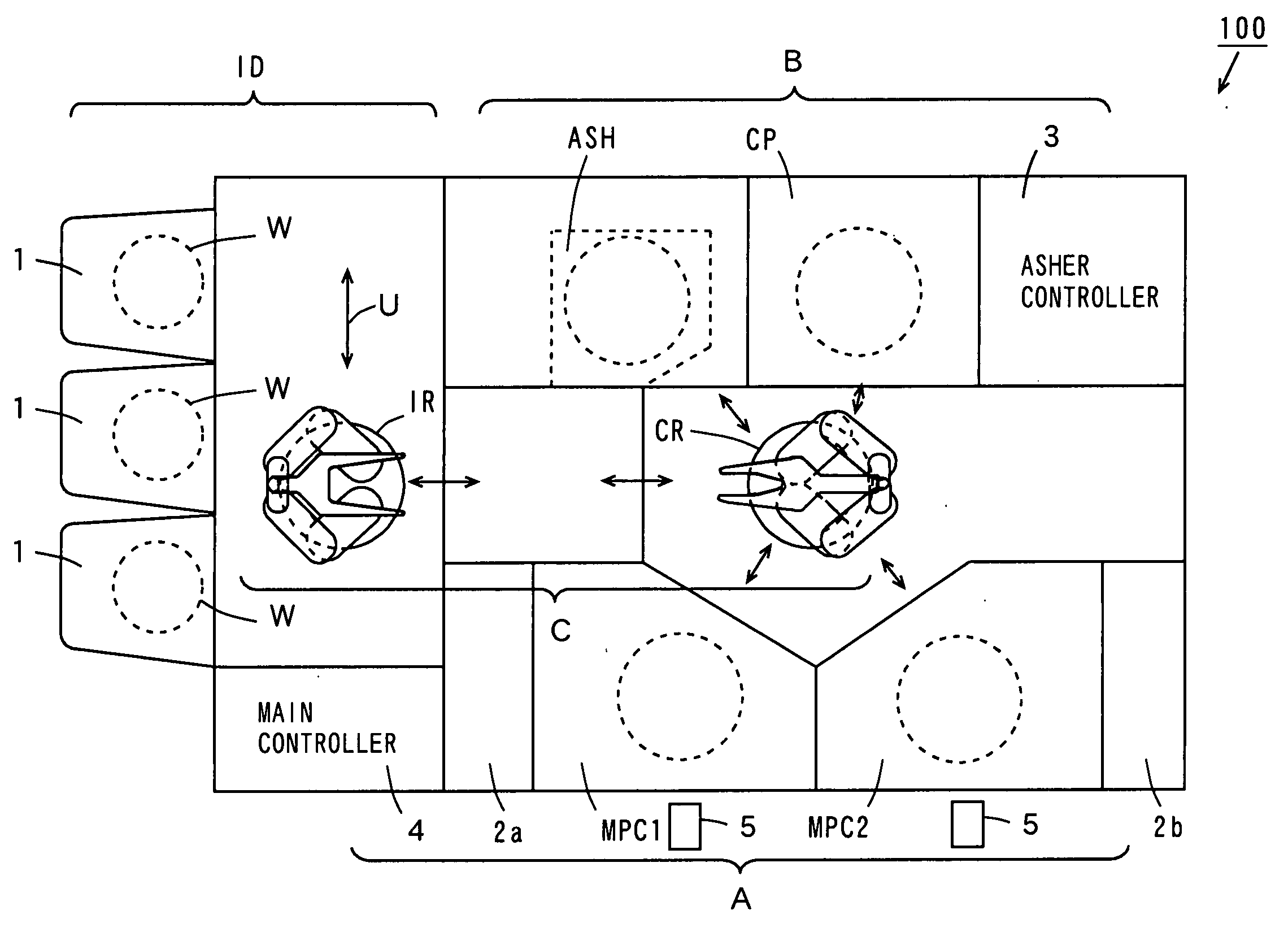

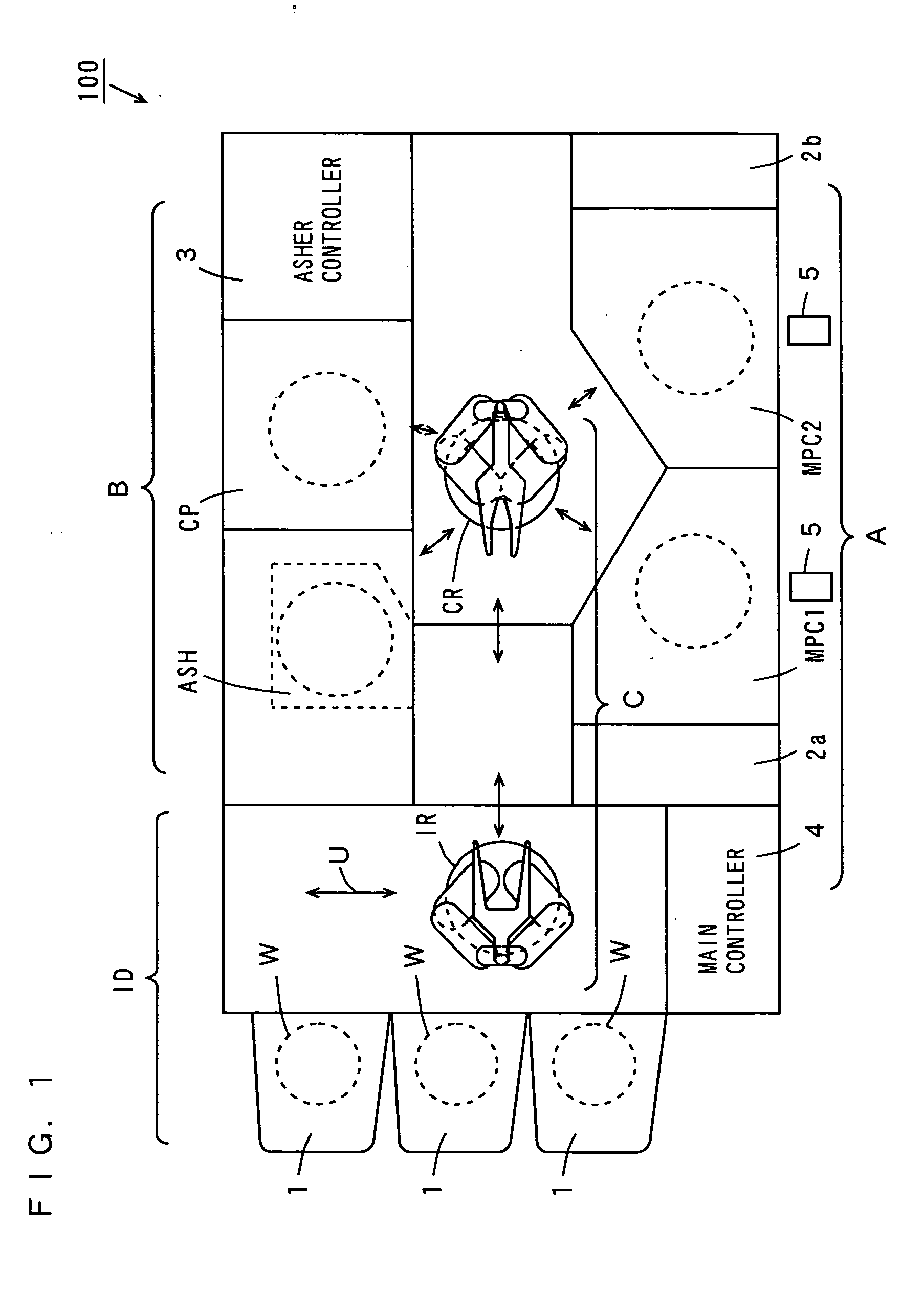

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

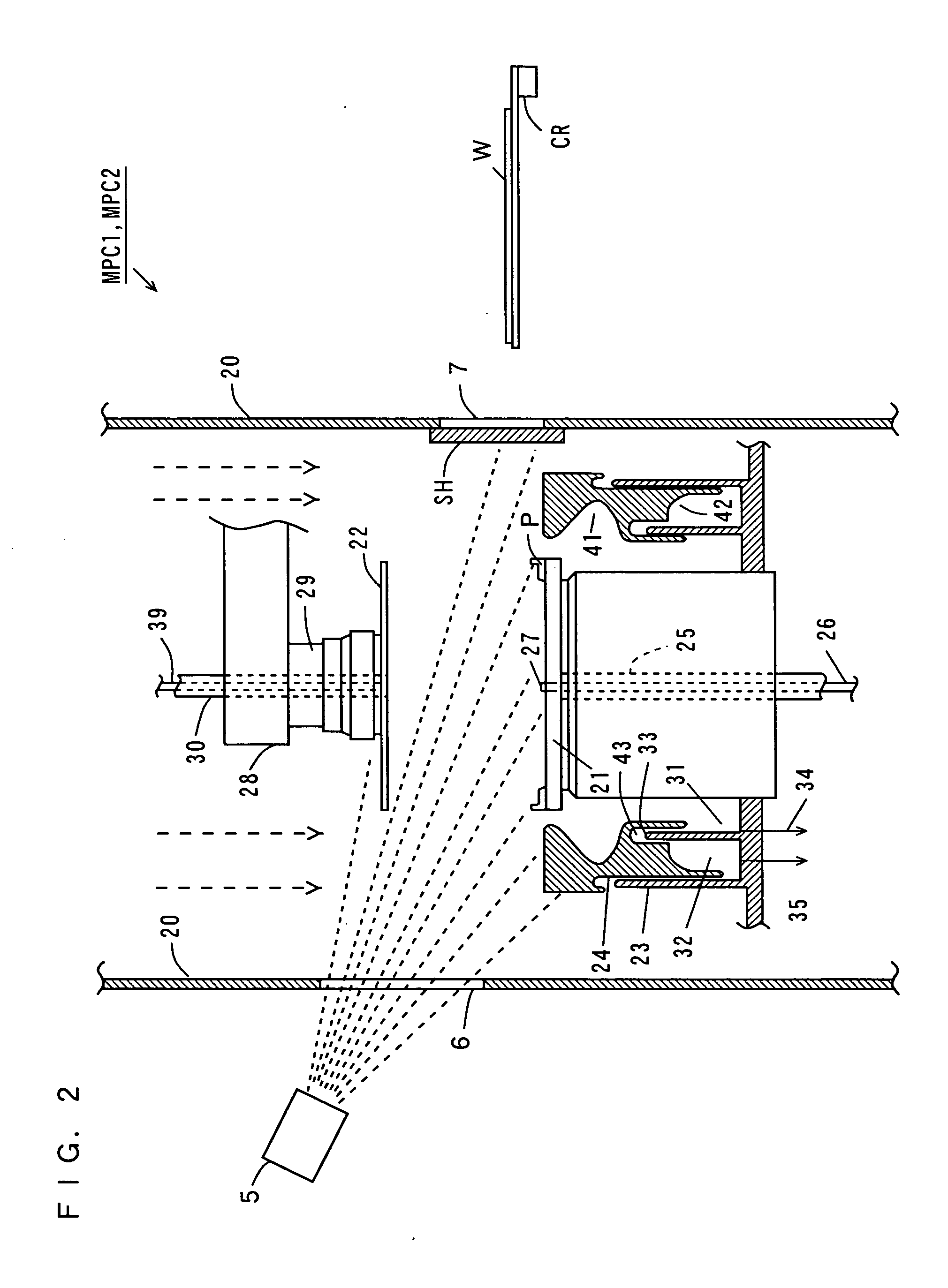

[0143] In each of an inventive example and a comparative example, a substrate W undergone hydrophobic-treatment with HF (hydrogen fluoride) was cleaned and dried under the following conditions, using the cleaning units MPC1 having the structure shown in FIG. 2.

Inventive Example

[0144] Holding pins P with the structure shown in FIG. 5 were used in the inventive example. As a material for each of the holding pins P, PEEK (PK-450CA) prepared by NIPPON POLYPENCO KABUSHIKI GAISHA was employed. During cleaning processing, the substrate W was cleaned with pure water while being rotated by the spin chuck 21. During drying processing, the substrate W was dried by shaking off the pure water while being rotated by the spin chuck 21. A polyimide resin film was employed for the transmitting window 6.

[0145] The shield plate 22 was fixed on a position about 70 meters above from the surface of the substrate W during the cleaning and drying processings.

[0146] During the cleaning processing, dryin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Transparency | aaaaa | aaaaa |

| Energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com