Gear milling positioning fixture for spiral bevel gear

A technology for spiral bevel gears and positioning fixtures, which is applied to gear teeth manufacturing devices, belts/chains/gears, gear teeth, etc., can solve the problems of destroying the positioning accuracy of fixtures and reducing production efficiency, and achieves simple structure, easy manufacture, and easy loading and unloading The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

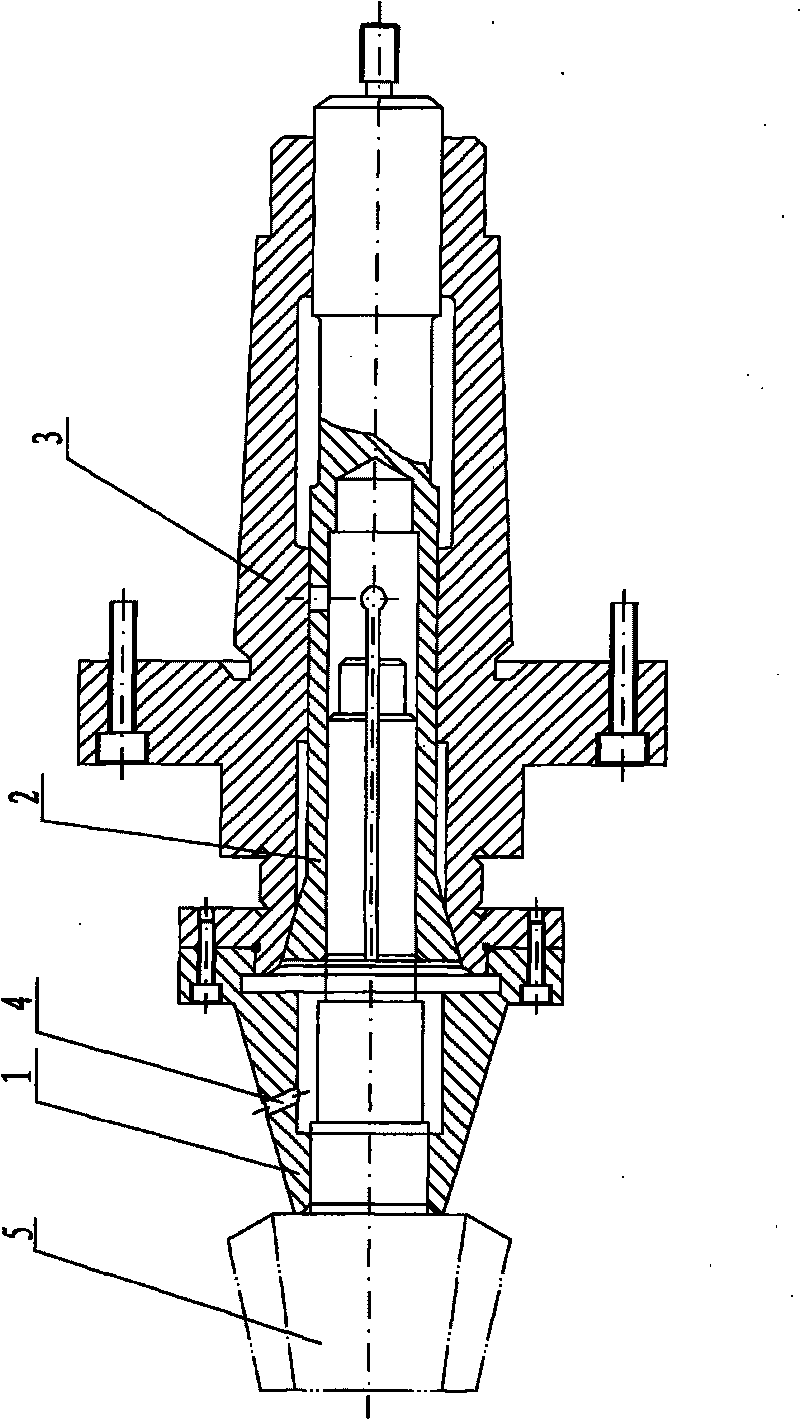

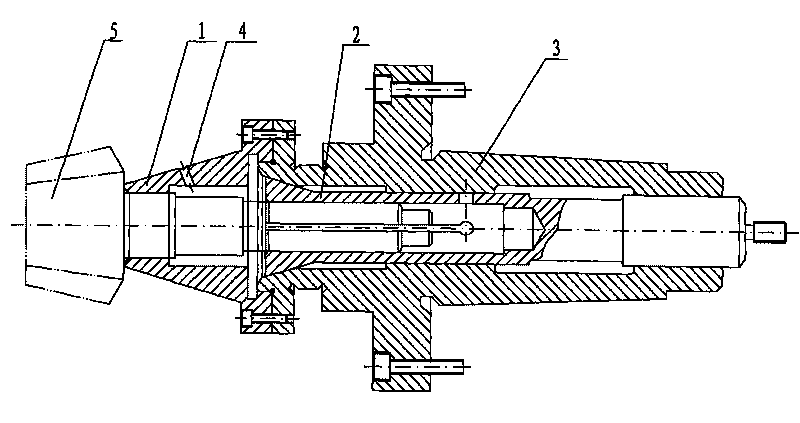

[0012] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

[0013] The spiral bevel gear milling positioning jig shown in the accompanying drawings includes a tie rod 2 coaxially fitted with the inner hole of the mandrel 3 , and a collet 1 coaxially connected to the left end of the mandrel 3 . The outer wall of the left end of the pull rod 2 and the inner hole of the mandrel 3 are a tapered sleeve structure, and the inner hole of the pull rod 2 is in clearance fit with the workpiece 5 . The chuck 1 is provided with a stepped hole, and the inner hole at the left end is in clearance fit with the journal of the workpiece 5 . The chuck 1 is provided with a hole penetrating through the outer wall of the large-diameter inner hole. In the present embodiment, the workpiece 5 is a spiral bevel gear of a miniature automobile drive axle, and its journal is Φ40 -0.019 0 mm, the inner hole of chuck 1 matc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com