Full-automatic loading and unloading device for large vehicle longitudinal beam hydraulic machine

A technology of automobile longitudinal beams and hydraulic presses, which is applied in the direction of feeding devices, positioning devices, storage devices, etc., can solve the problems of inaccurate positioning of sheet metal, long processing cycle of beams, and high labor intensity of workers, so as to improve production efficiency and save The effect of manpower and time, fast loading and unloading speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

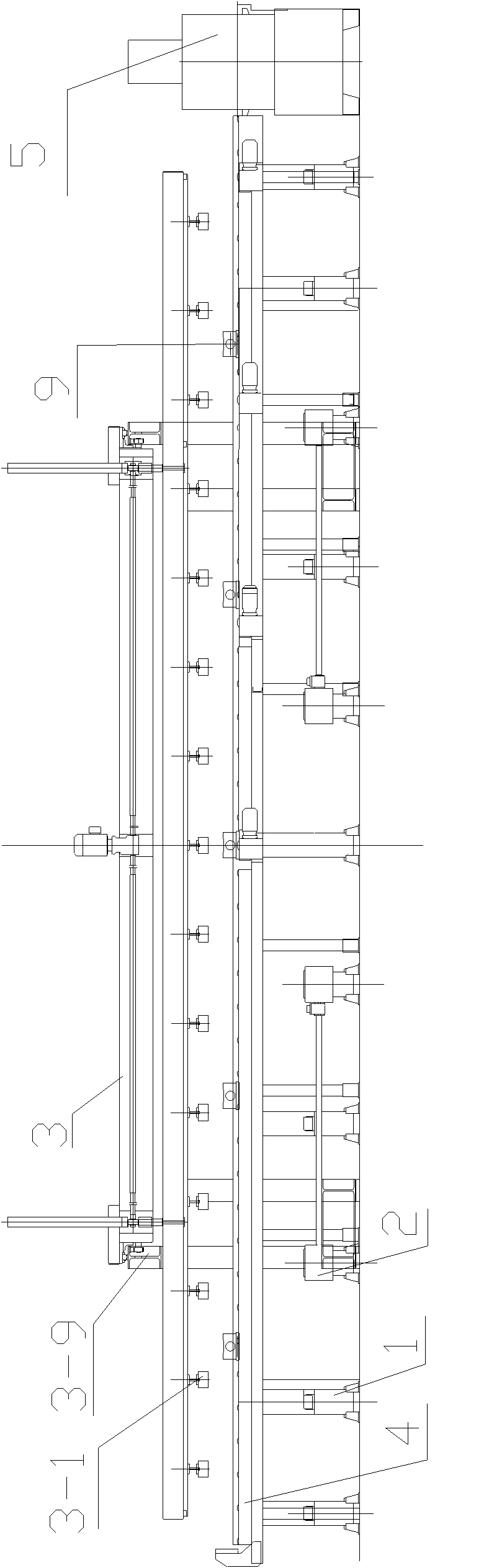

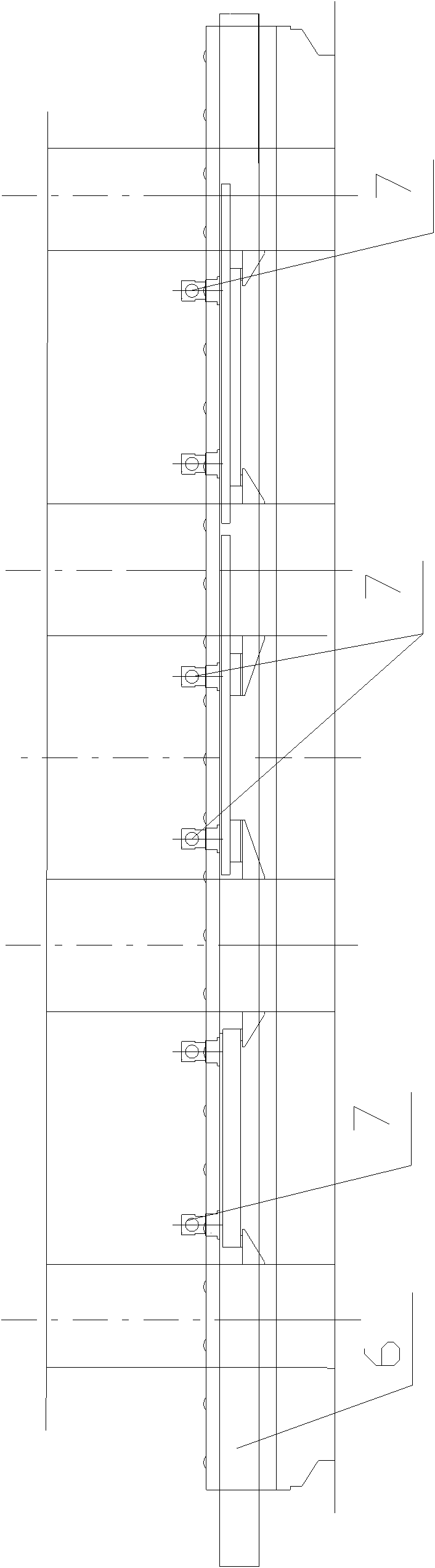

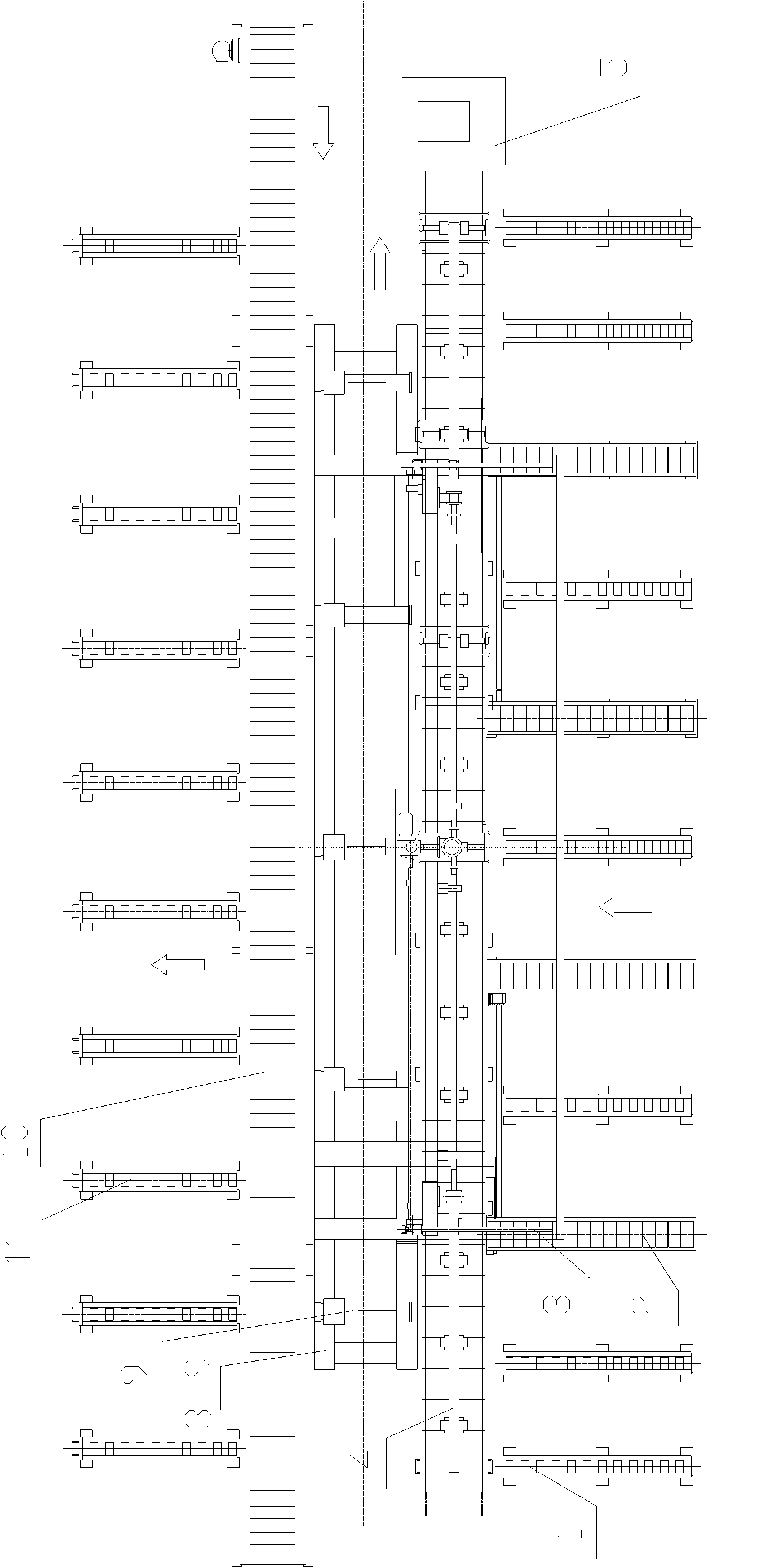

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings: Please refer to Figure 1 to Figure 5 , the present invention mainly includes: comprising a feeding roller table 1, a feeding chain plate 2 arranged parallel to the feeding roller table 1, an outer feeding mechanism 3 positioned above the feeding chain plate 2, and a The outer input mechanism 4, the oiling mechanism 5 and the inner input mechanism 6 connected sequentially from the outer input mechanism 4, the inner pushing mechanism 7 perpendicular to the inner input mechanism 6, and the inner output chain plate 8 perpendicular to the inner pushing mechanism 7 , the outer output chain plate 10 connected with the inner output chain plate 8, the outer pushing mechanism 9 perpendicular to the outer output chain plate 10 and the blanking roller tabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com