Motorbicycle lamp shade mounting and connection structure

A technology for motorcycles and headlights, which is applied to lampshades, motor vehicles, road vehicles, etc. It can solve the problems of cumbersome disassembly and assembly, inconvenient disassembly and assembly of lampshades, and complex structures, and achieves simple structure, convenient loading and unloading operations, and a connection structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

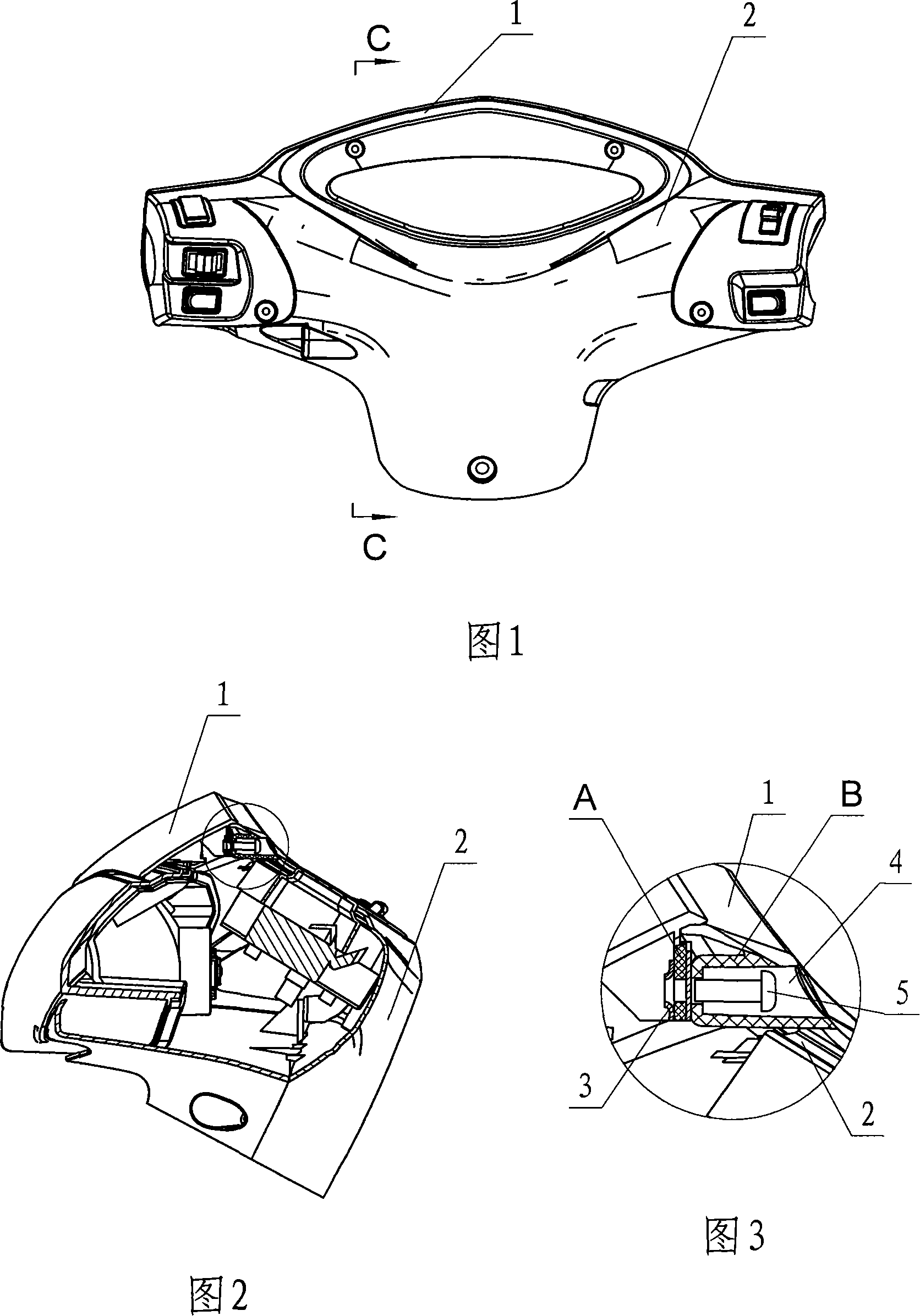

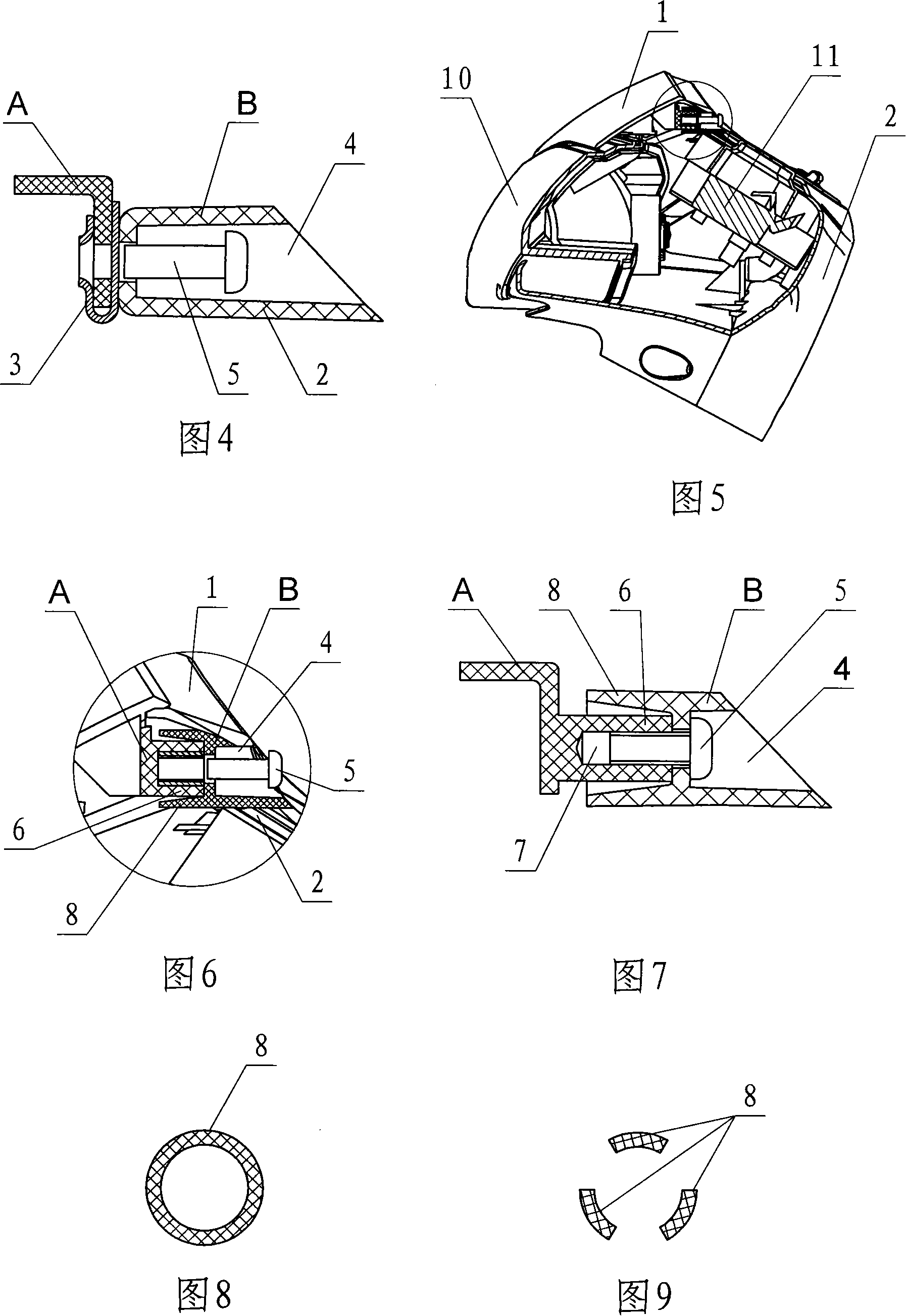

[0020] As shown in Fig. 5, Fig. 6 and Fig. 7, a connecting seat A is integrally provided on the lamp cover 1, and a connecting seat B is integrally provided on the instrument cover 2, and the connecting seat B of the instrument cover 2 is provided with The counterbore 4, the connecting seat A of the lampshade 1 is provided with a boss 6, and the boss 6 is axially provided with a screw hole 7 corresponding to the counterbore 4, and the lamp 10 and the instrument 11 are installed on the lampshade 1 respectively. , After the instrument cover 2 is installed, let the boss 6 of the connecting seat A on the lamp cover 1 correspond to the counterbore 4 of the connecting seat B on the instrument cover 2, and the bolt 5 passes through the counterbore 4 and directly connects with the screw hole 7 of the boss 6 connected. Under the condition that the structural size and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com