Device for automatically coating lubricants on hot-expanding seamless steel tubes

A technology of seamless steel pipe and coating device, which is applied in the direction of device and coating for coating liquid on the surface, can solve the problems of difficult mass production and cost reduction, uneven lubricant coating, high working intensity, etc. Achieve the effect of improving production efficiency, changing the phenomenon that manual cannot accurately control thickness, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

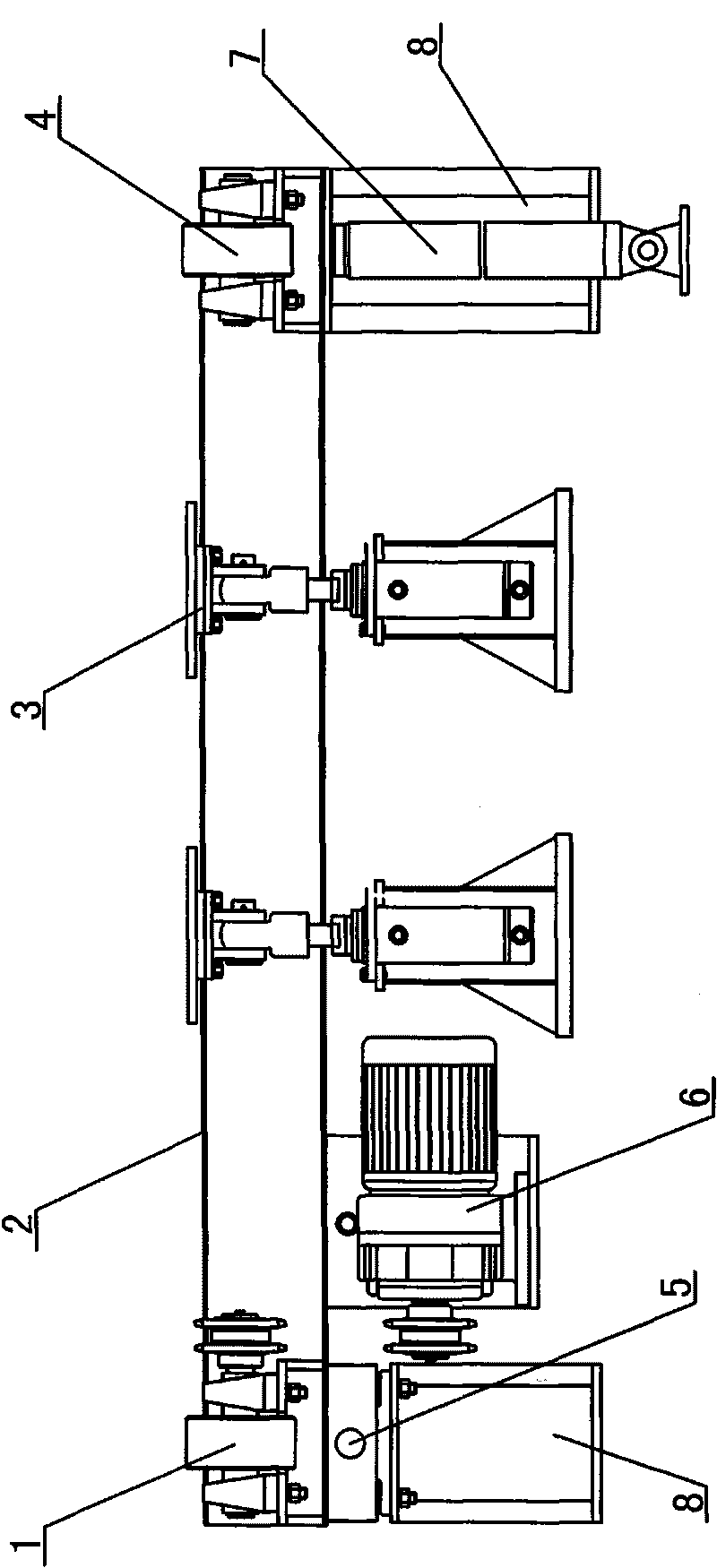

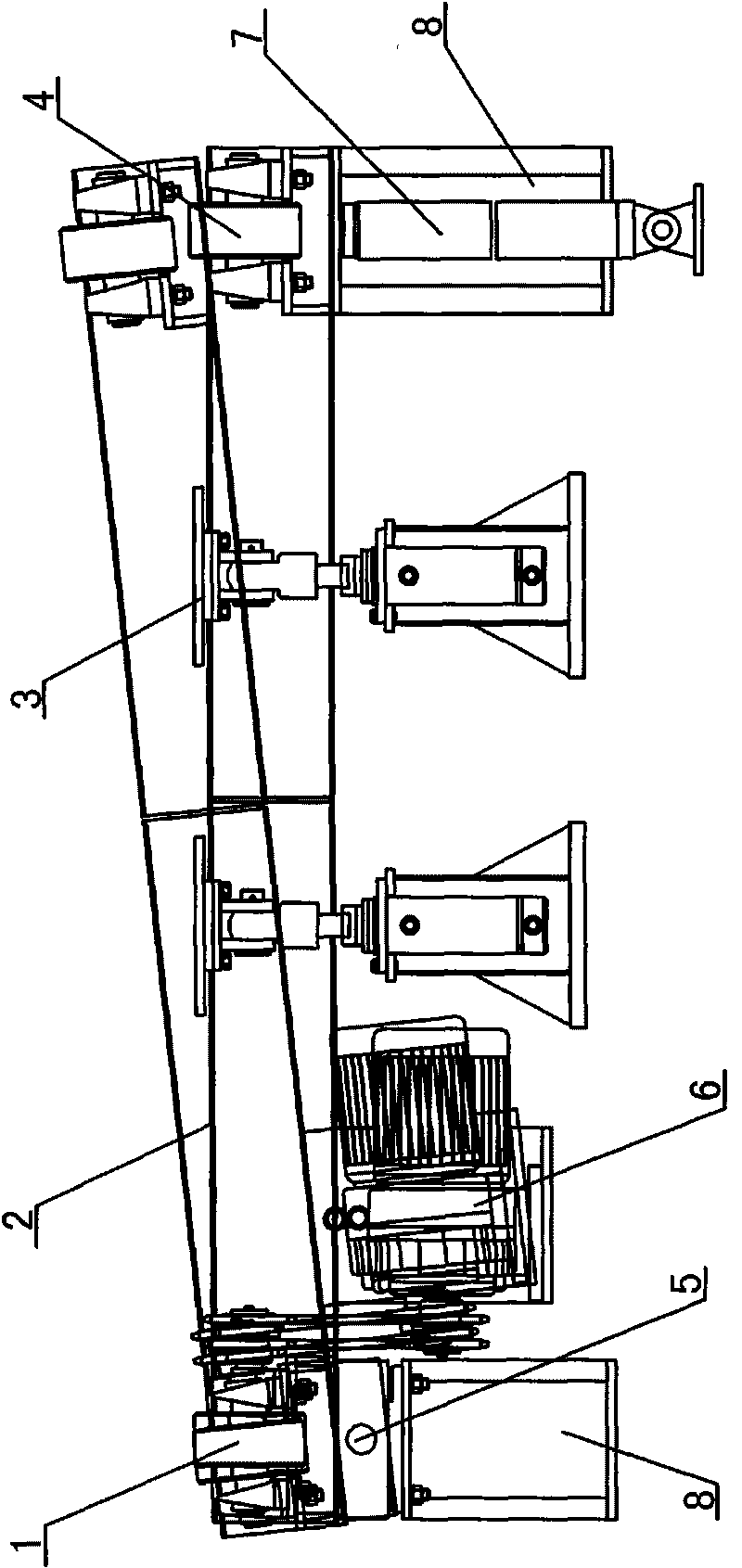

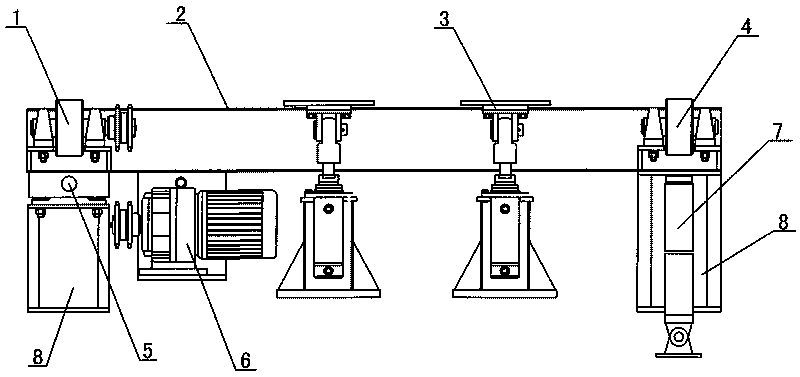

[0015] Such as Figure 1-2 As shown, the thermal expansion seamless steel pipe lubricant automatic coating device of the present invention includes a driving roller 1, a platform frame 2, a trusteeship mechanism 3, a driven roller 4, a rotating bracket 5, a transmission motor 6, a hydraulic lifting System 7 and machine base 8, the two ends of the platform frame 2 are respectively connected to the rotating bracket 5 and the hydraulic lifting system 7 and placed on the left and right machine bases 8; the driving roller 1 on the left side of the device is driven by the transmission motor 6 and drives The steel pipe and the right driven roller 4 rotate, the hydraulic lifting system 7 and the right machine base 8 are fixed on the ground and the right side of the platform is raised and tilted by the extension of the hydraulic cylinder; the left and right trusteeship mechanisms 3 are close to both sides The rollers are mounted and consist of a hosting platform and hydraulic cylinders...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com