Full-automatic infinitely-long finger jointing machine

An infinitely long and fully automatic technology, which is applied in the jointing of wooden veneers, wood processing equipment, manufacturing tools, etc., can solve the problems of low production efficiency, large processing quality fluctuations, and small application range of finger joint machines, and achieve reduction Frictional resistance and downtime for clearing glue, improving finger joint quality, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

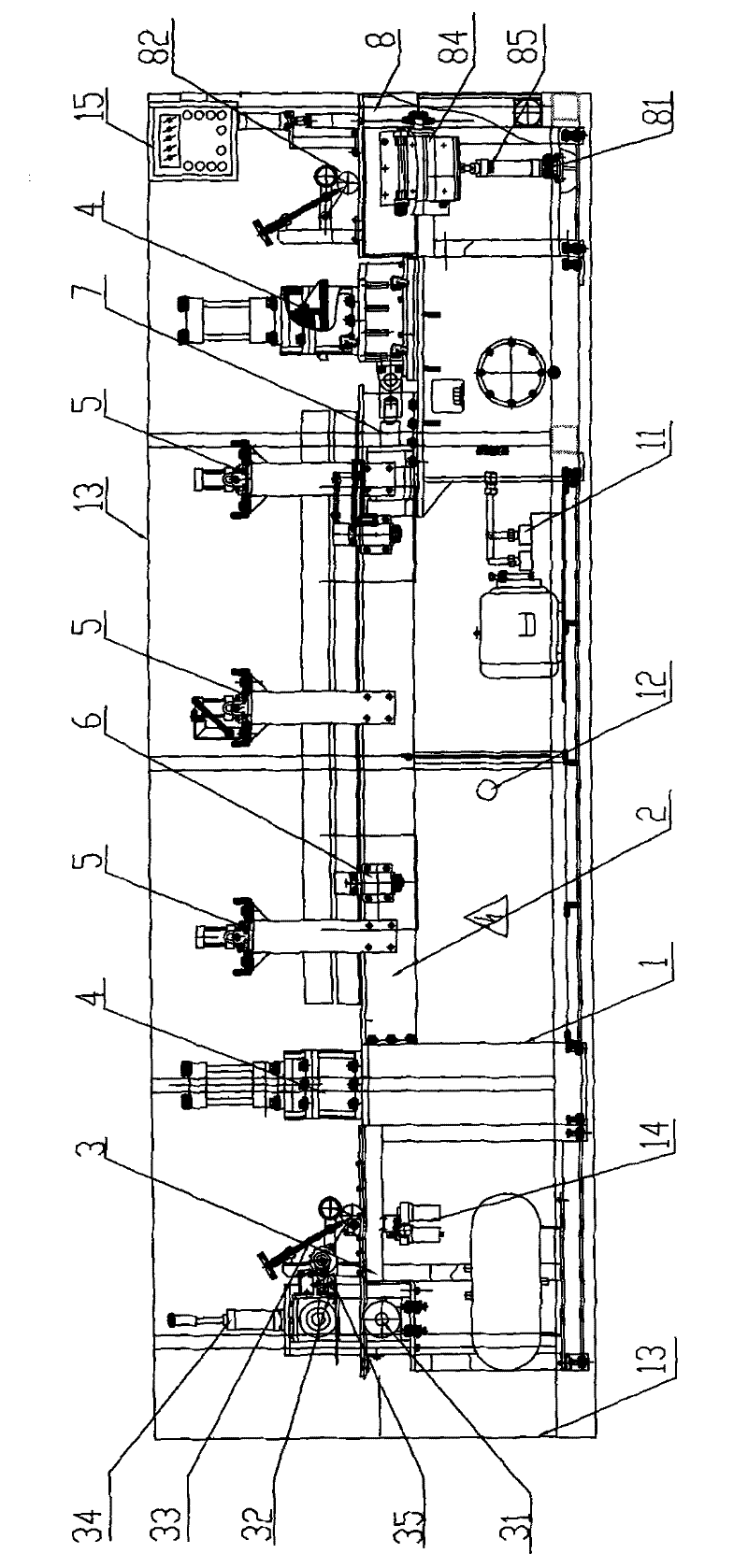

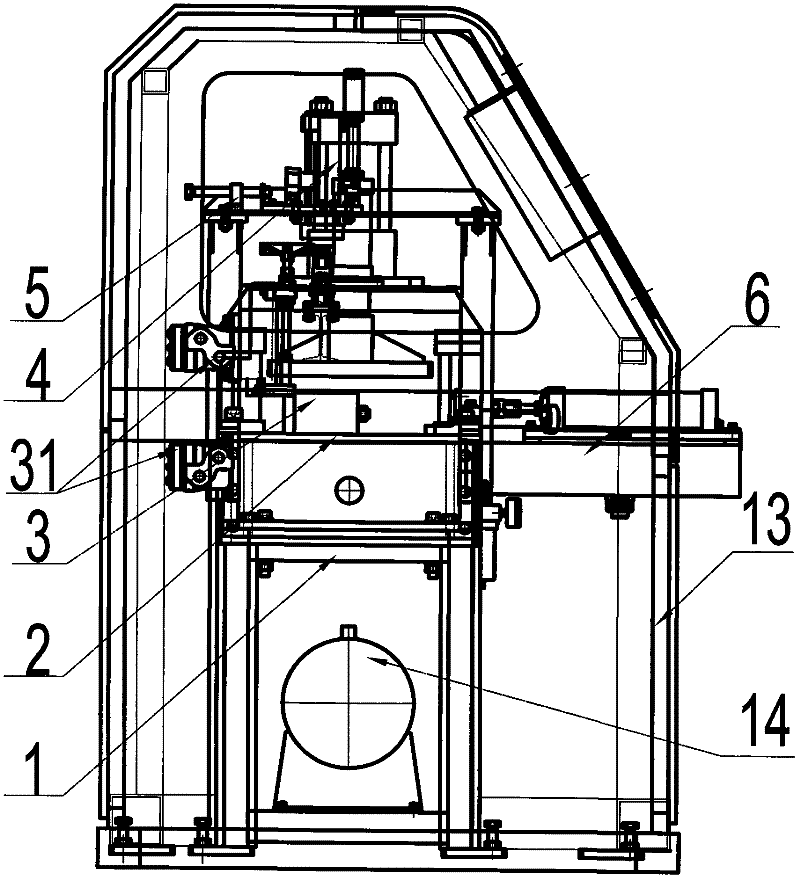

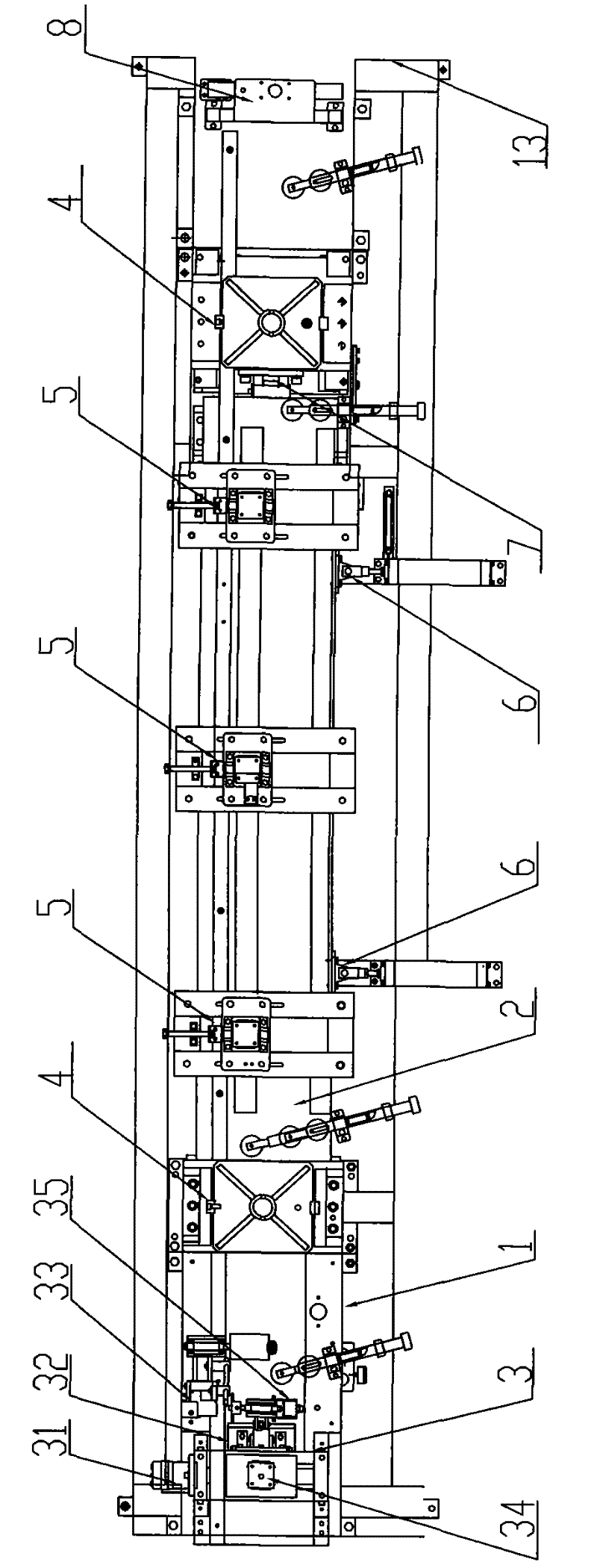

[0025] Example 1, see figure 1 , 2 . The workbench is horizontal and fixed on the frame 1. The workbench 2 is made into two parts: the static workbench and the feed workbench. The hydraulic positive presser foot 4 is composed of two sets of hydraulic cylinders. The feed pre-connection mechanism 3, the rear presser foot of the hydraulic positive presser foot 4, the pneumatic upper pressure bar 5, and the pneumatic side pressure bar 6 are installed on the static workbench. The feed pre-connection mechanism 3 includes a pair of vertically installed hydraulic motors 31 The shaft end of the upper and lower hydraulic motor 31 is equipped with self-balancing rotating material roller 32, thickness compensation elastic roller group 33, the shaft end of thickness compensation elastic roller group 33 is connected with the shaft end of air-controlled swinging lateral guide wheel 34, and the length detection rotary encoder is pre-connected 35 is installed on the cantilever of the air-con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com