Auto quenching device and auto quenching method

A kind of quenching equipment and automatic technology, which is applied in the direction of quenching device, heat treatment equipment, furnace, etc., can solve the problems of affecting the mechanical properties of the motor shaft, affecting the straightness of the motor shaft, and the damage of the motor shaft structure, so as to ensure straightness, Avoid damage, avoid the effect of slight bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

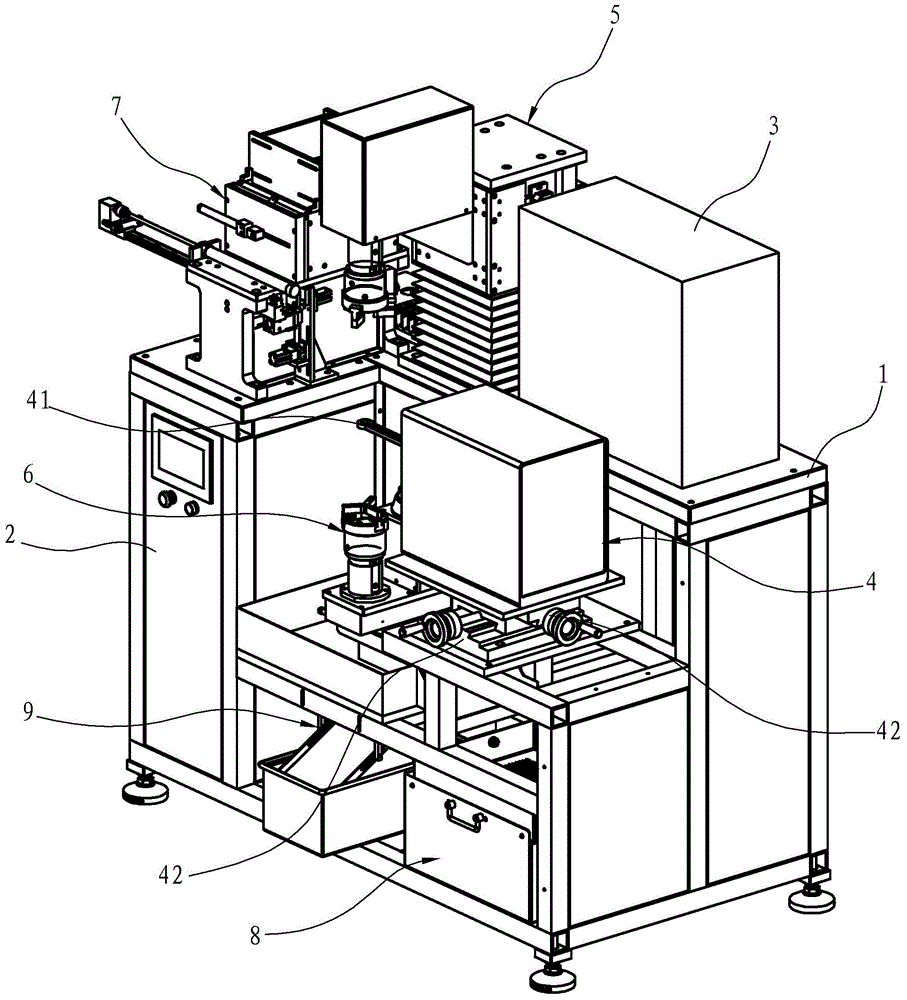

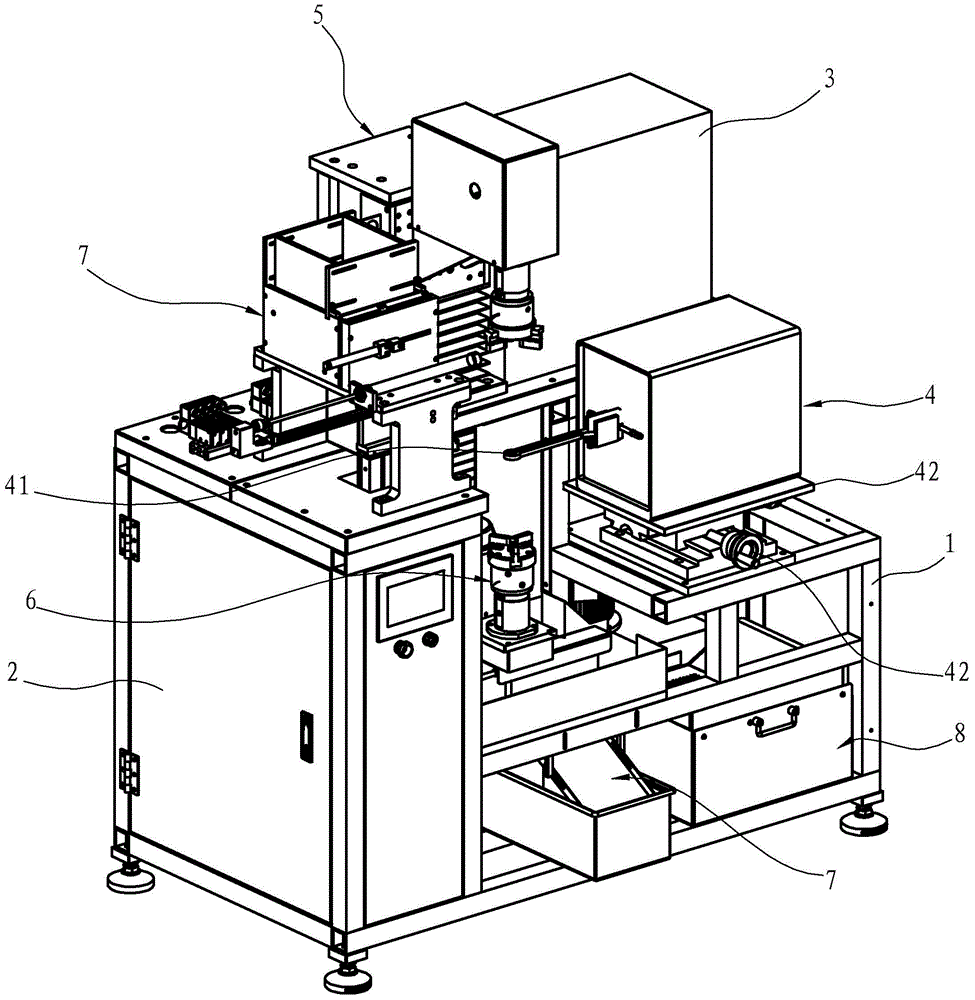

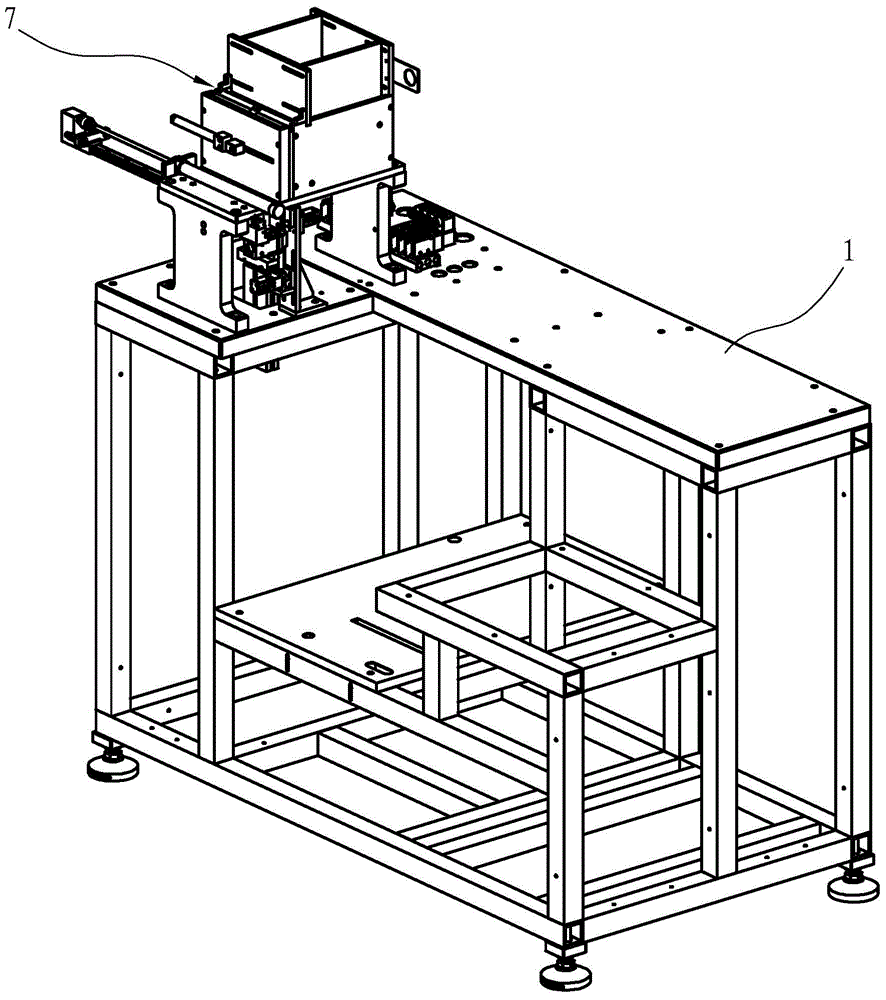

[0061] Such as Figures 1 to 4 As shown, the present invention discloses an automatic quenching equipment, which is used for quenching shaft workpieces, and is especially suitable for quenching the ends of motor mandrels, including a frame 1, and an automatic feeding mechanism 7 arranged on the frame 1, Rotary lifting mechanism, material receiving mechanism 7, reflux cooling mechanism 8, electric control box 2, high frequency machine 3 and induction machine 4, etc. Wherein, the high-frequency machine 3 is used to generate high-frequency current on the induction coil 41; the induction coil 41 connected to the high-frequency power circuit is horizontally arranged on the induction machine 4, and the induction coil 41 is connected with the induction machine 4, and the induction machine 4 Two sliding plates 42 for adjusting the planar position of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com