Self-adaptation convexity change hot rolled plate shape control model

A control model and self-adaptive technology, applied in the direction of contour control, etc., can solve the problems of unreasonable proportional crown changes in the rolling process, affecting the target crown control situation, and the rolling process is not stable enough

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

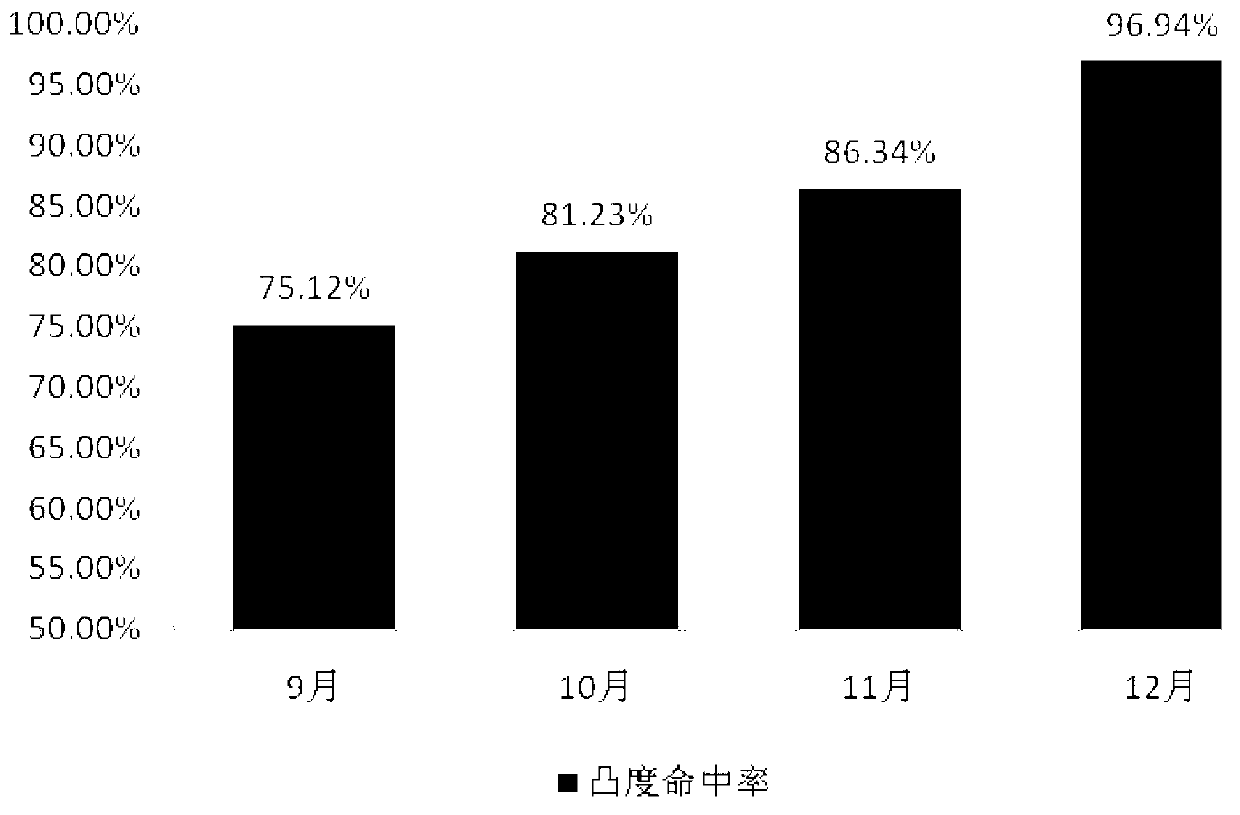

[0031] The 1580mm hot rolling production line of Shougang Qianshan Iron and Steel Co., Ltd. produces a wide variety of products, and the same batch of wide, narrow, thin, and thick steel strips spans a large range. During the production process, due to the lack of adaptive crown changes in the original strip shape control model, there are too many outlet crown settings for each rack. Mechanical and unreasonable places, resulting in uneven rolling and even reset of the target crown, which seriously affects the control accuracy of the target crown. Aiming at this phenomenon, the self-adaptive crown change hot-rolled strip shape control model of the present invention is adopted to improve, the outlet crown setting is more reasonable, the target crown reset phenomenon is greatly reduced and almost disappears, and the crown control hit rate is improved.

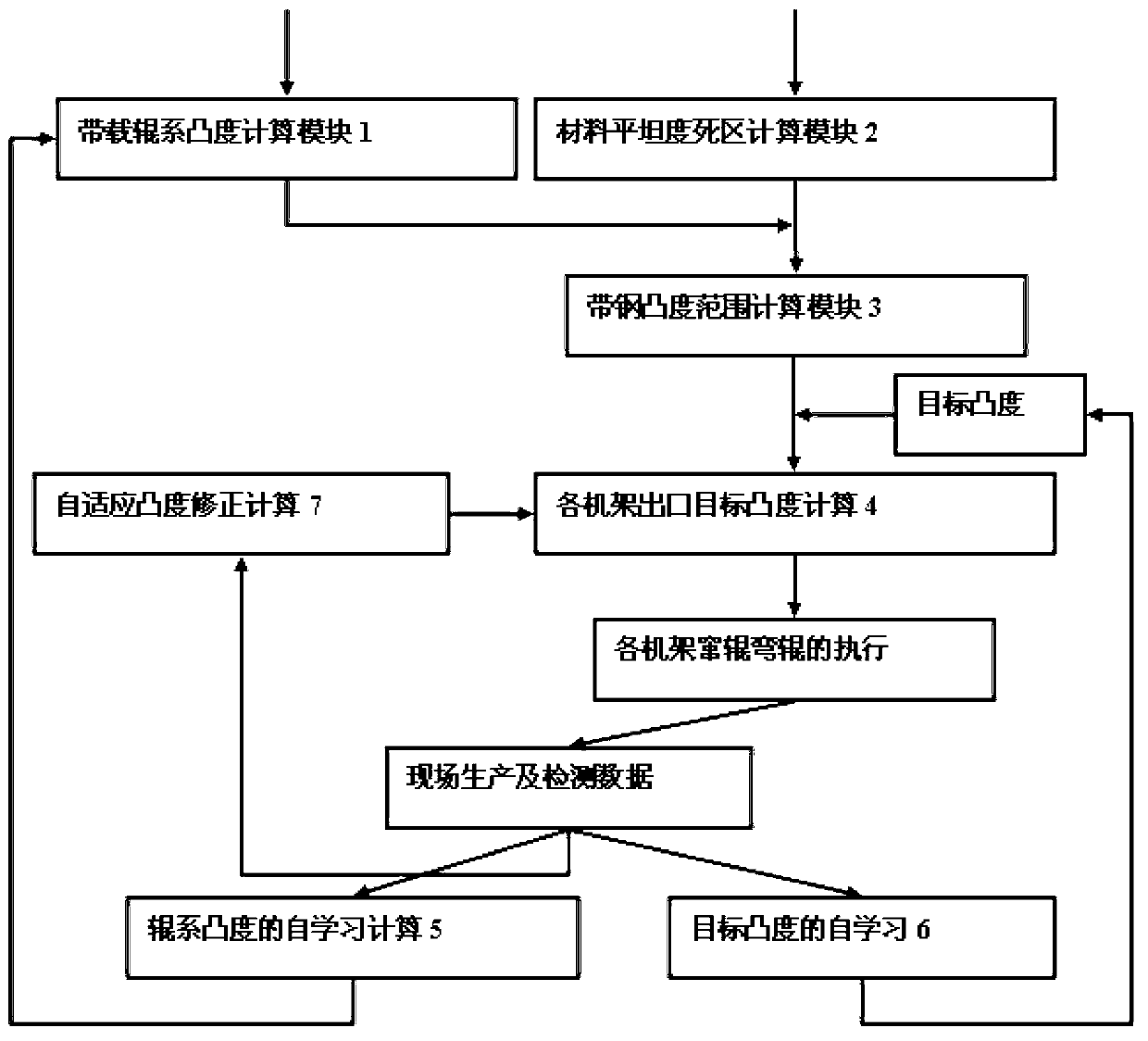

[0032] In the implementation process, according to the content of the invention, the various modules of the adaptive crown change...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com