Cone warping machine and method for operating same

A slit warping machine, warping technology, applied in the direction of warping machines, textile and papermaking, other manufacturing equipment/tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

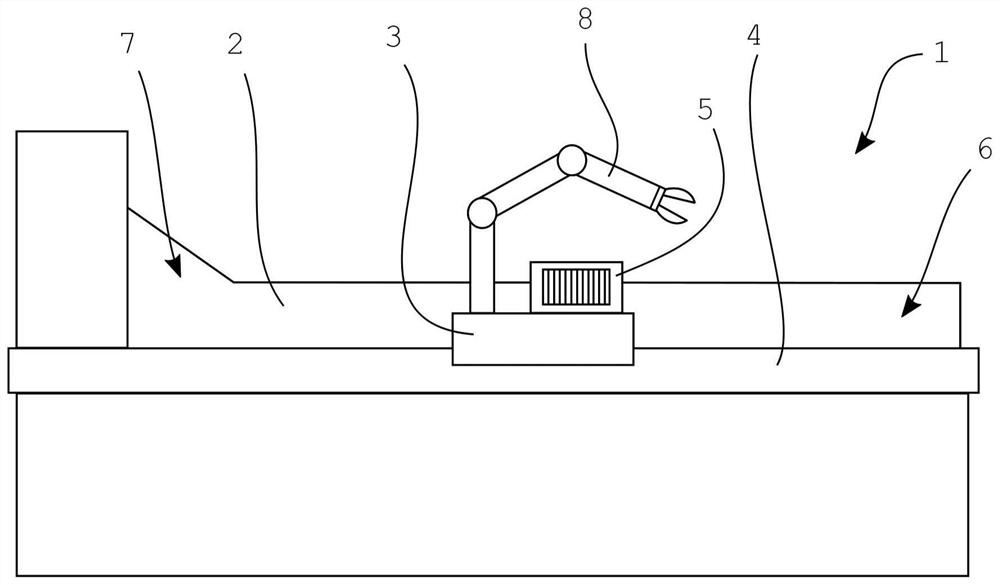

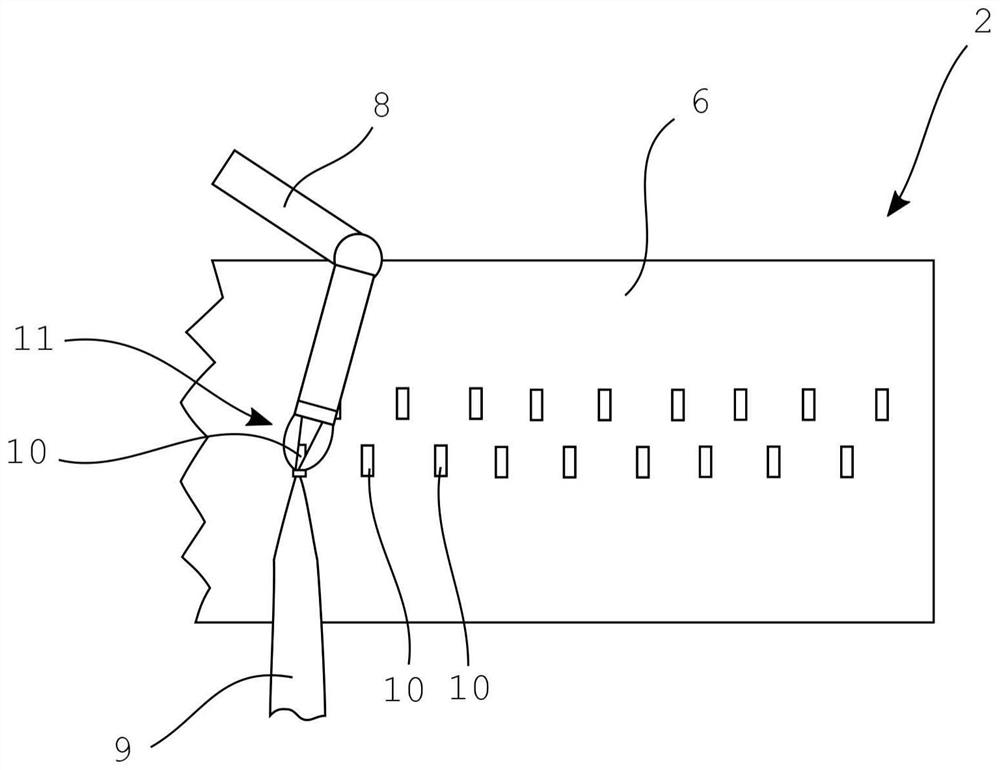

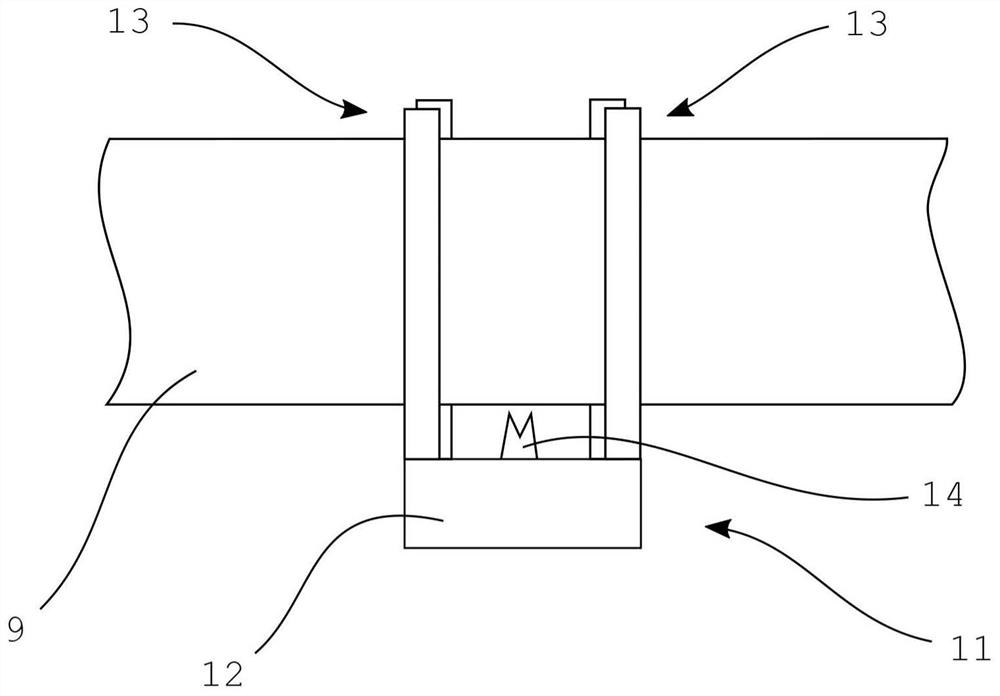

[0046] figure 1 A schematic diagram of a section warping machine 1 according to the invention is shown. The section warping machine 1 has a warping cylinder 2 and a warping table 3 . The warping cylinder 2 can be driven in rotation by an electric motor and, moreover, the warping cylinder can be moved parallel to its longitudinal axis. The warping table 3 is guided and displaceable on a side rail 4 , wherein the warping table 3 moves parallel to the longitudinal axis of the warping cylinder 2 . The warping reed 5 is placed on the warping table 3, through which the yarn, for example from the yarn creel, is supplied to the section warping machine and bundled. The bundled yarns together form a warp sliver.

[0047] In order to start the warping process, first the warping cylinder 2 and the warping table 3 are moved relative to each other so that the warping table 3 is opposite the warping initial zone 6 of the warping cylinder 2 . The sliver of warp thread is now fixed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com