Preparation method of special core material for exterior thermal insulation, fireproof, thermal insulation and decorative integrated board

A technology for external thermal insulation of external walls, fire prevention and thermal insulation, applied in thermal insulation, building components, buildings, etc., can solve the problems that the insulation core material has no full sealing effect, rock wool is easily damaged by moisture, and has low fireproof performance, so as to improve moisture absorption Moisture absorption and mildew, improve the integrity of the plate, and improve the effect of crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

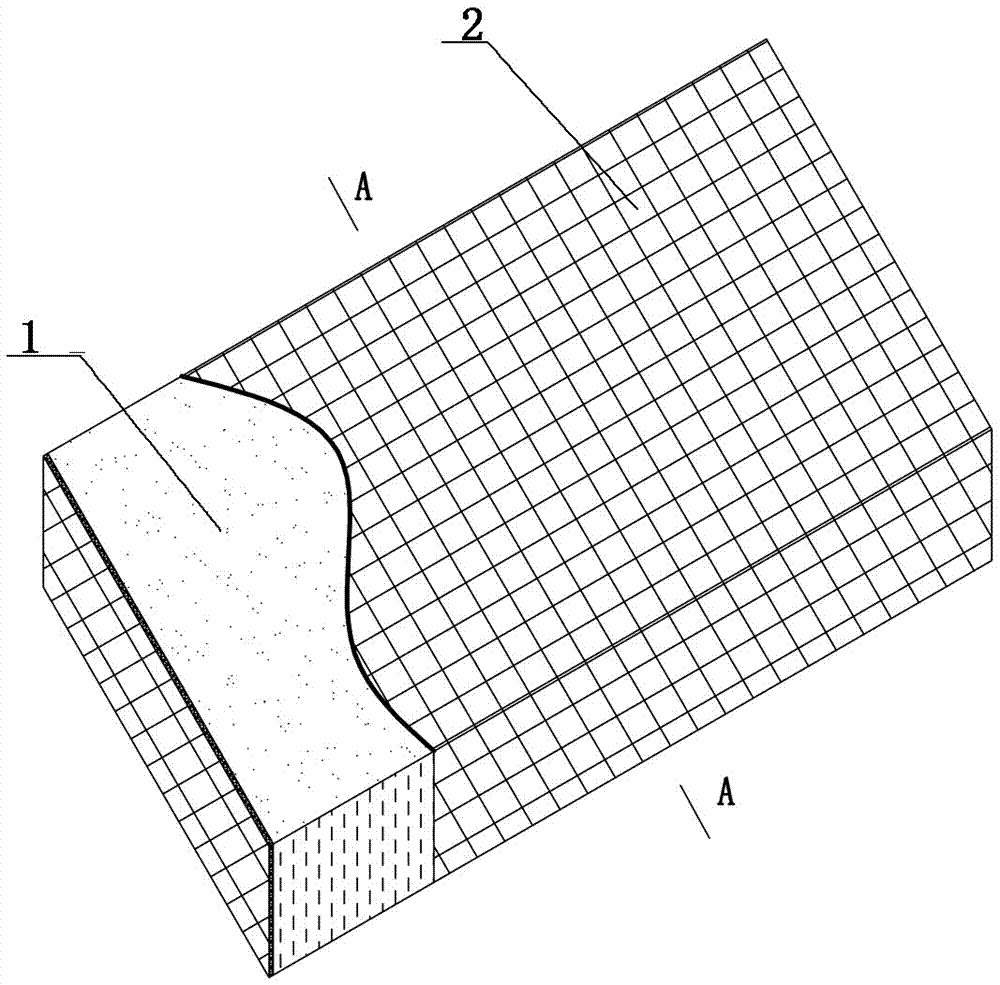

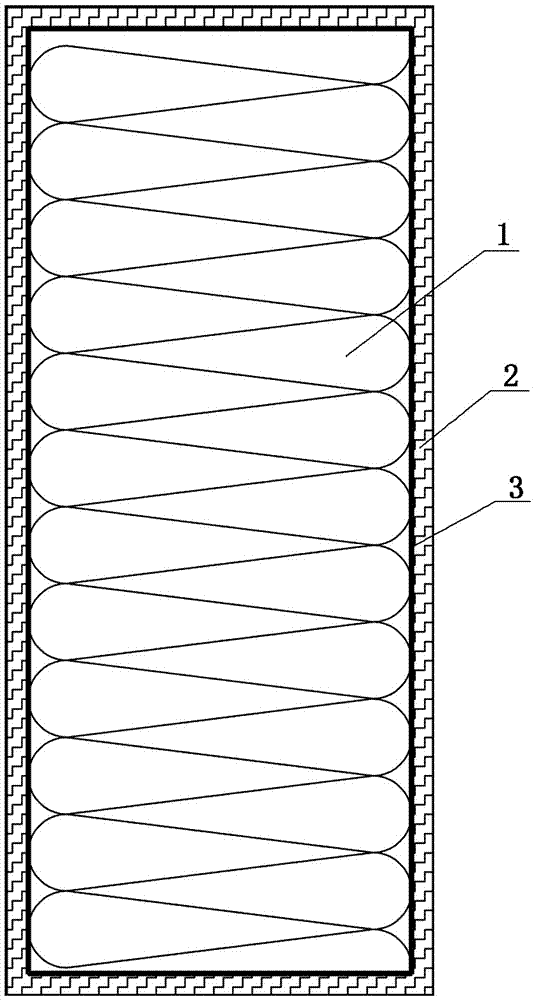

[0036] Such as figure 1 and figure 2 , the present invention relates to a special core material for an integrated board with external thermal insulation, fire protection, thermal insulation and decoration, including a block-shaped standing silk rock wool slab 1, characterized in that: the six sides of the standing silk rock wool slab 1 are all wrapped There is a high-strength basalt fiber mesh cloth 2, and the basalt fiber mesh cloth 2 is bonded and fixed to the outer surface of the standing silk rock wool slab 1 through a flexible building structure adhesive 3. The flexible building structure adhesive 3 is coated on six sides of the vertical fiber rock wool slab 1 to form a sealing layer. The basalt fiber mesh c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com