Blanking floating cutter structure and blanking die with same

A floating knife and blanking die technology, applied in the field of blanking dies, can solve problems such as burrs and waste, scrapped blanking parts, and coil deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

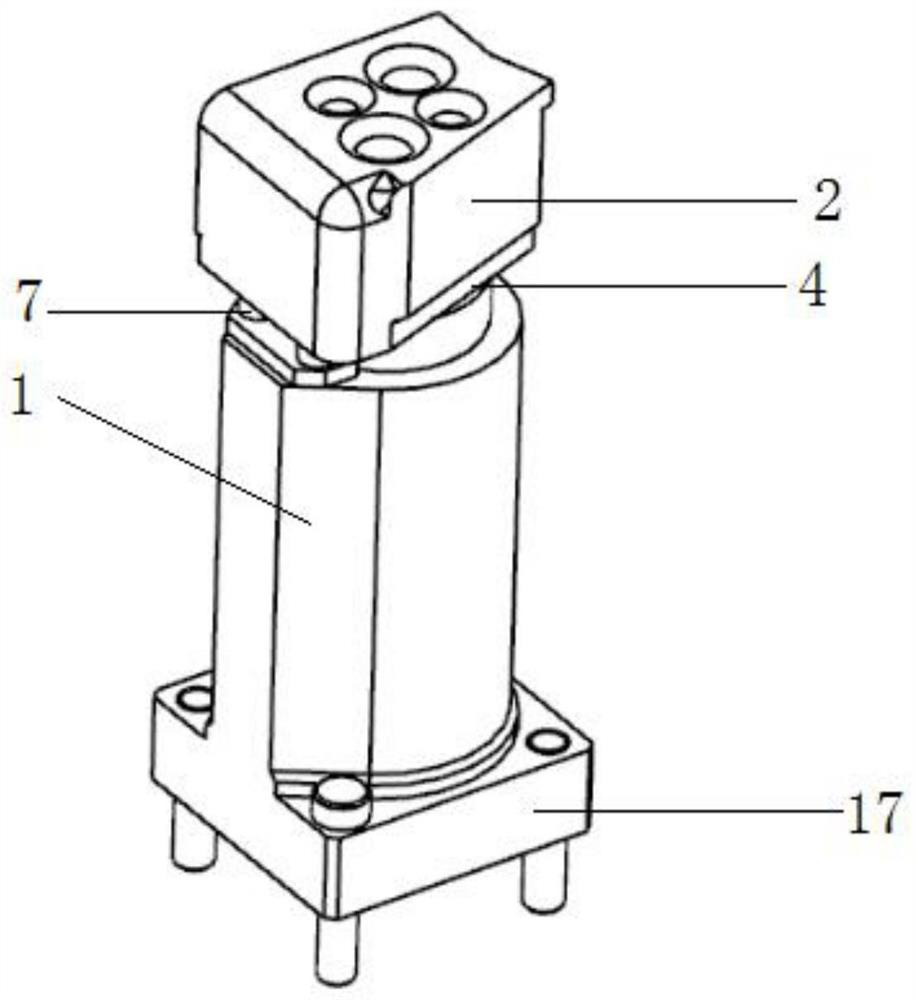

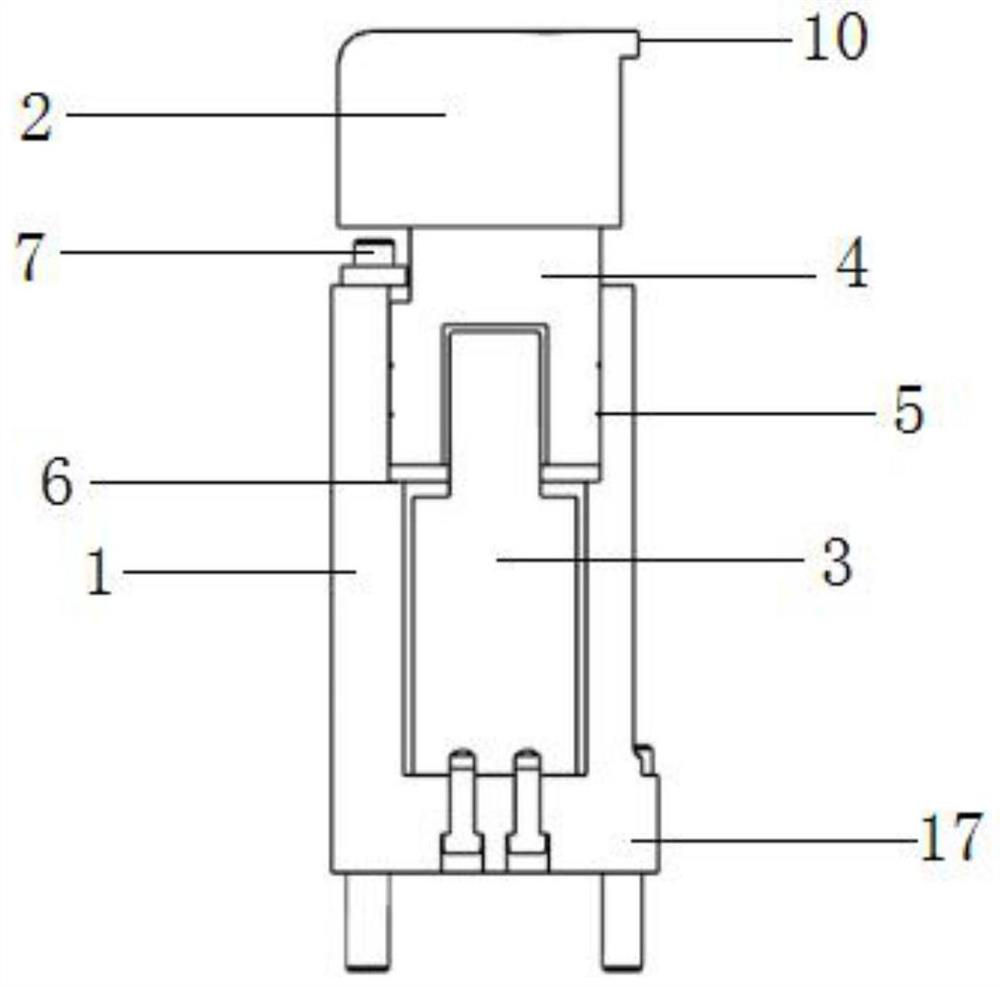

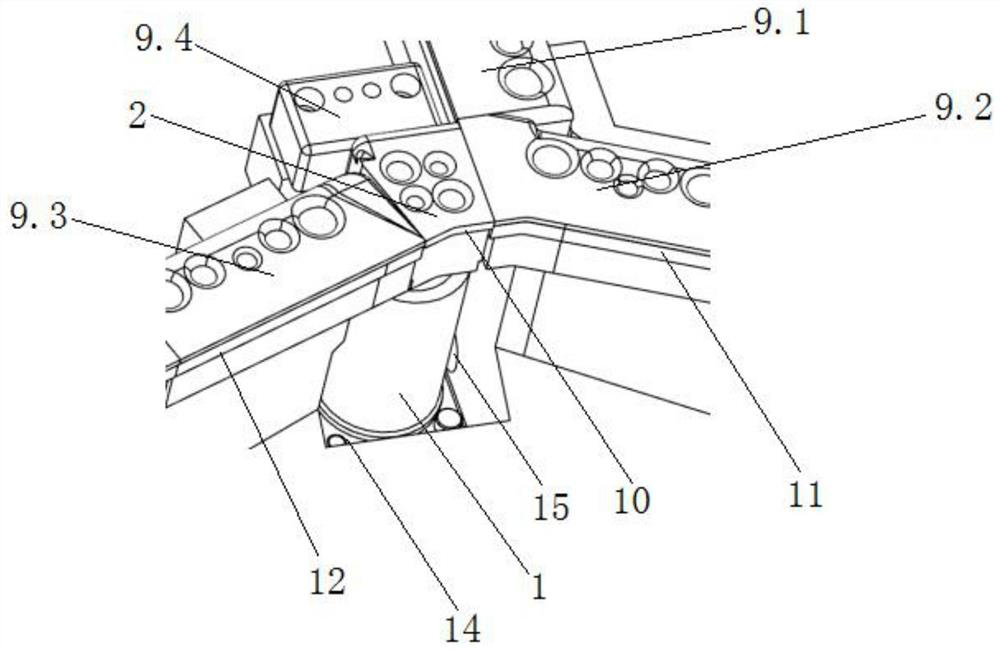

[0025] Such as figure 1 - The blanking floating knife structure shown in 2 includes a sleeve 1, a spring 3 and a drive block 4 coaxially fixed on the top of the spring 3 are coaxially arranged in the sleeve 1, and the bottom of the spring 3 is fixed to the sleeve 1 by screws Inside, the floating punch 2 is fixed on the top of the driving block 4, and one side surface of the floating punch 2 is provided with a floating chamfering surface 10 that can cooperate with the edge of the trimming knife, and the driving block 4 is coaxially fixed on the spring 3 The cylindrical driving block on the top, the upper annular inner surface of the sleeve 1 and the circumferential surface of the driving block 4 are clearance fit to avoid the radial shaking of the driving block 4. Lubricating oil is injected inside to ensure the stability of the axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com