Plate buckle belt

A plate buckle and belt technology, applied in the direction of fasteners, belt buckles, clothing belts, etc., can solve the problems of belt buckle weight, pin buckle hole deformation, and affect the appearance of automatic buckle belts, and achieve the effect of ensuring the appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

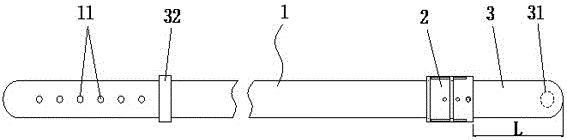

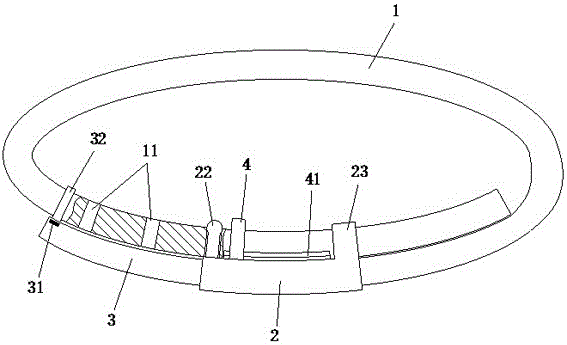

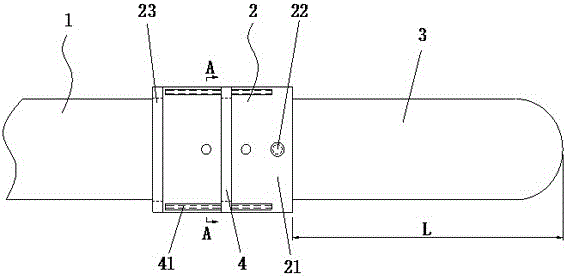

[0023] Embodiment one: if Figure 1~4 As shown, a buckle belt includes a belt body 1 and a buckle 2, the front part of the belt body is used to install the buckle 2, and several jacks 11 are uniformly distributed along the length direction of the belt body at the rear part, and the buckle 2 is arranged on the rear part of the belt body. A length of L-band head 3 is left between the buckle and the end of the belt body front.

[0024] In this embodiment, the buckle includes a fixing plate 21 for fixing the belt body. The rear end of the inner surface of the fixing plate is provided with an O-shaped guide sleeve 23 for the movable end of the belt body to pass through, and the middle part of the front end is provided with a The insertion rod 22 of the jack, the end of the insertion rod is provided with a ball head whose outer diameter is larger than the hole diameter of the jack; both sides of the inner surface of the buckle are provided with slide rails 41, and also include a bol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com