Hydraulic control system for reciprocating test beds

A technology of hydraulic control system and test bench, which is applied in the direction of fluid pressure actuation system components, fluid pressure actuation devices, accumulator devices, etc., can solve problems such as unsatisfactory operation status and complex structure, and achieve a high degree of automation , low operating cost, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

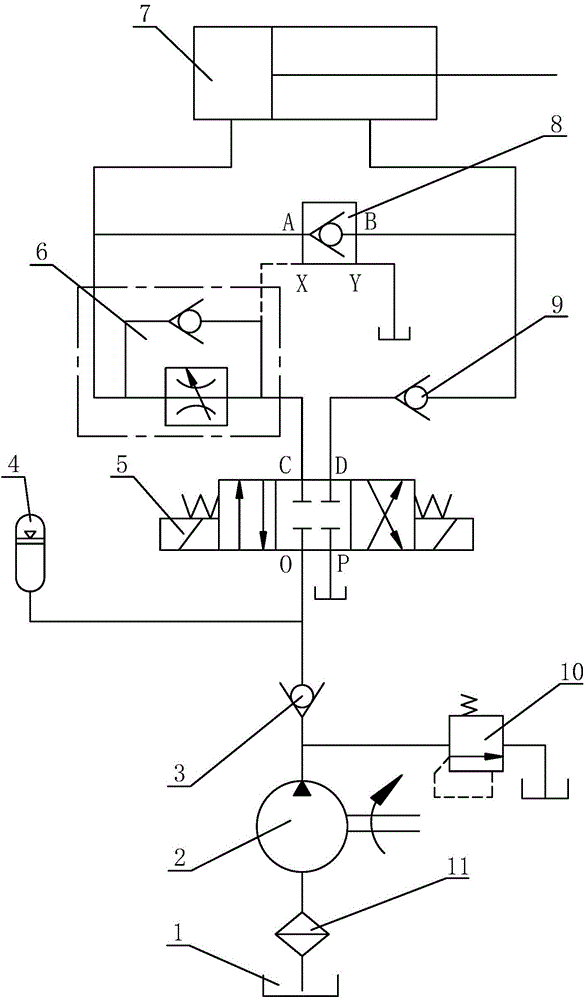

[0020] Such as figure 1 A hydraulic control system for a reciprocating test bench is shown, including an oil tank 1, a hydraulic pump 2 for supplying high-pressure hydraulic oil to the system, and a hydraulic cylinder 7 for driving the reciprocating motion of the component under test, as well as a reversing valve 5, a one-way speed regulation Valve 6 and hydraulic control check valve 8; port C and port D of the reversing valve 5 communicate with the rodless chamber and the rod chamber of the hydraulic cylinder 7 respectively, and port P of the reversing valve 5 communicates with the port O The ports are respectively communicated with the oil outlet of the oil tank 1 and the hydraulic pump 2, the oil outlet of the hydraulic pump 2 is provided with an accumulator 4, and the accumulator 4 can play a role when the hydraulic pump 2 is not working. The role of energy storage and pressure maintenance. The one-way speed regulating valve 6 is arranged on the pipeline between the port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com