Pipeline robot with pipe diameter self-adaption function

A technology of spiral pipes and robots, which is applied in the direction of pipes/pipe joints/fittings, special pipes, pipe components, etc., can solve the problems of lack of execution plans, etc., and achieve the effects of simple structure, increased size, and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

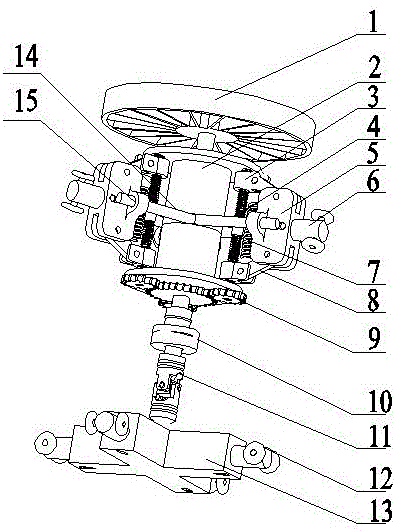

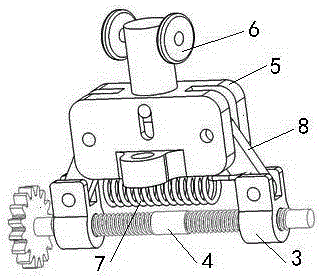

[0015] like Figure 1 to Figure 2 The shown pipe diameter adaptive spiral pipeline robot includes a planetary reducer 2, and the input end of the planetary reducer 2 is connected with a driving impeller 1; the output end of the planetary reducer 2 is connected with a fixed guide through a universal joint 11. There is a safety clutch 10 between the planetary reducer 2 and the universal joint 11; the outer shell of the planetary reducer 2 is provided with a number of ball screws 4 with opposite screw directions at both ends. Both ends are covered with nut pairs 3, and the nut pairs 3 are connected together by tension springs 7; the nut pairs 3 at both ends are connected with wheel bases 5 through connecting rods 8, and the wheel bases 5 are provided with rotating axial and The rotation axis of the planetary reducer 2 is not parallel to the drive wheel 6 ; the output end of the planetary reducer 2 and the input end of the ball screw 4 are connected together through a gear train 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com