Automatic metal plate bending equipment

A metal plate and plate technology, applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problem that the plate workpiece cannot be sent to the bending station, etc., and achieve the effect of convenient operation and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

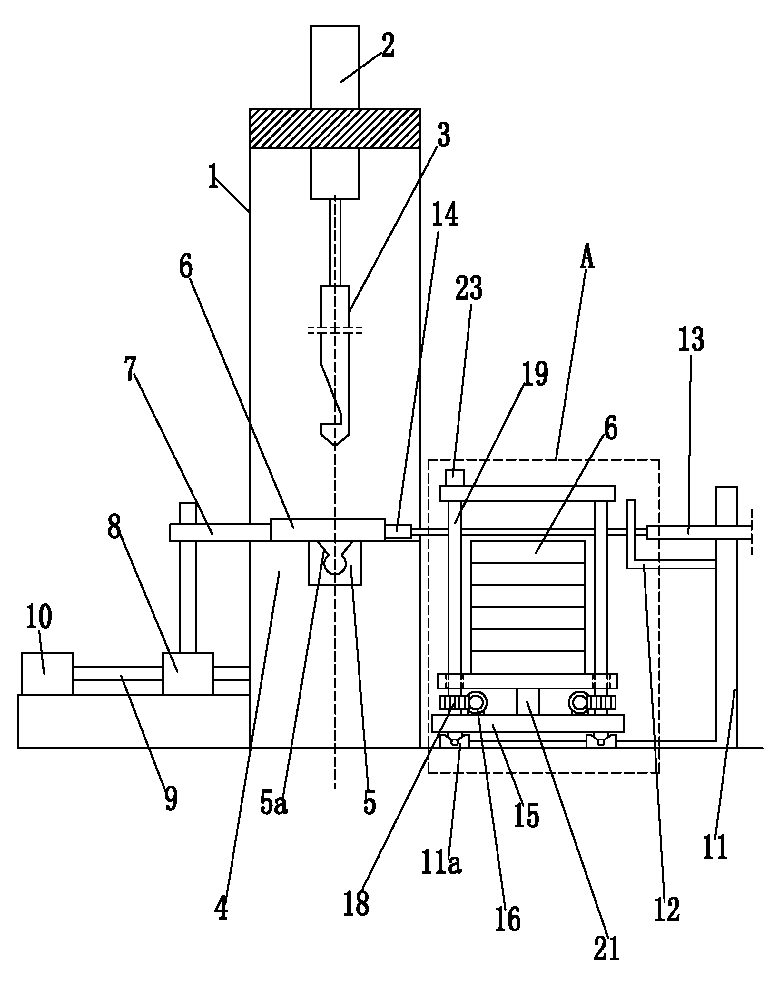

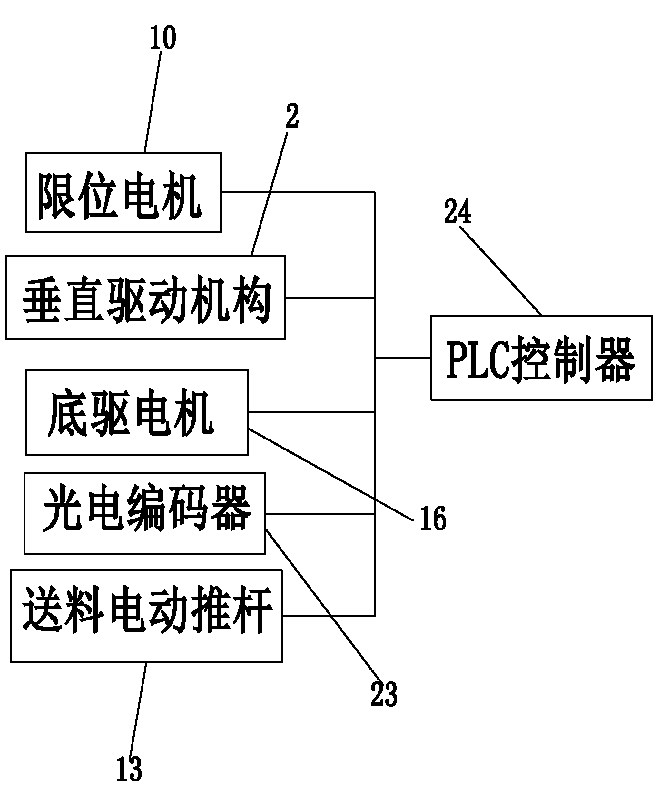

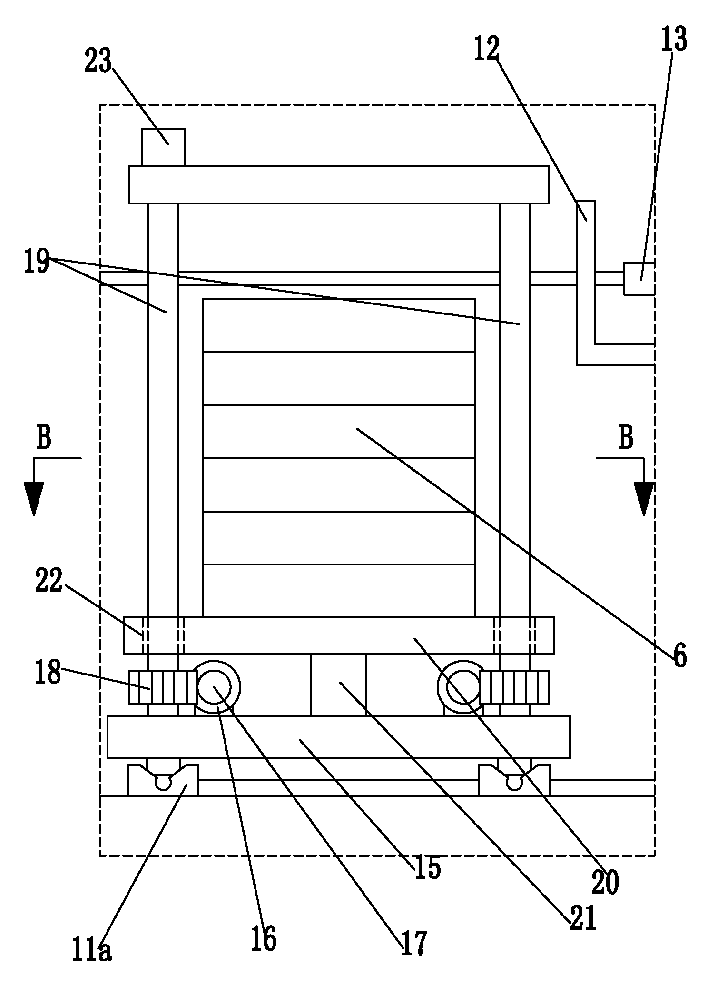

[0019] Such as Figure 1-4 As shown, a kind of automatic sheet metal bending equipment includes a main base 1, and also includes a loading platform 4 for placing sheet metal workpieces 6, and also includes a bending die 3 for bending sheet metal workpieces 6, and also includes a set The vertical drive mechanism 2 on the main base 1 for driving the bending die 3 to lift vertically to carry out the bending process also includes a concave module 5 installed on the material setting table 4 and provided with a concave mold groove 5a , also includes a PLC controller 24, also includes a pushing unit that can push the plate workpiece 6 onto the concave module 5, and also includes a movable limit mechanism for limiting the bending position of the plate workpiece 6, and the vertical drive mechanism 2 is controlled by PLC Device 24 control.

[0020] The above-mentioned movable limit mechanism includes a limit stop plate 7 for limiting the plate workpiece 6, and also includes a limit scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com