Adjustable composite pressure-boosting air intake system

A compressor and supercharger technology, applied in the direction of charging system, combustion air/combustion-air treatment, internal combustion piston engine, etc., can solve the problems of variable altitude power recovery, etc., to ensure power recovery and reduce the volume of the intake system , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the above objects, features and advantages of the present application more obvious and comprehensible, the present application will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

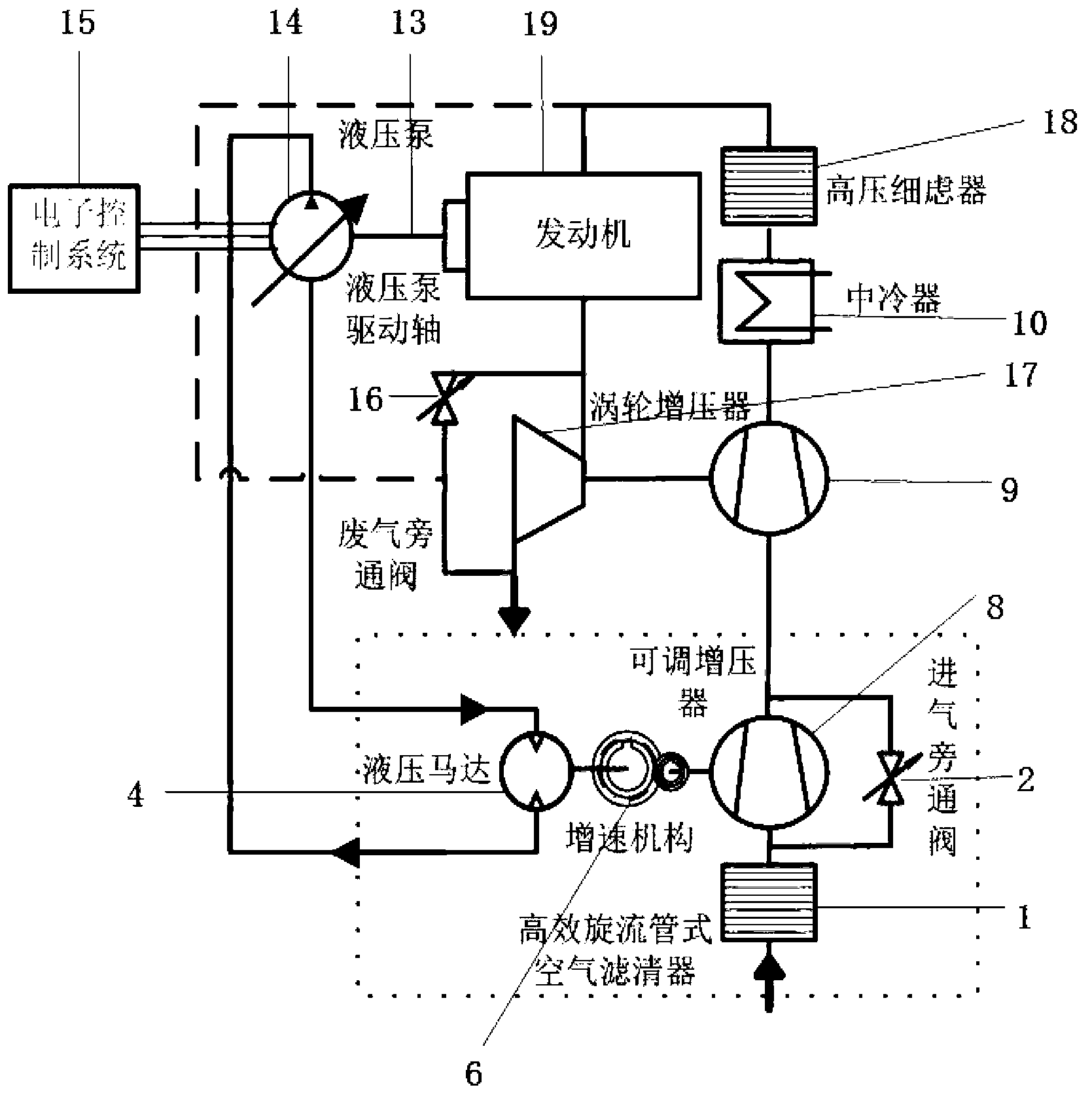

[0040] refer to figure 1 , which shows a structural diagram of an adjustable speed compound supercharging system described in the embodiment of the present application, which may specifically include:

[0041] Two-stage supercharger, where,

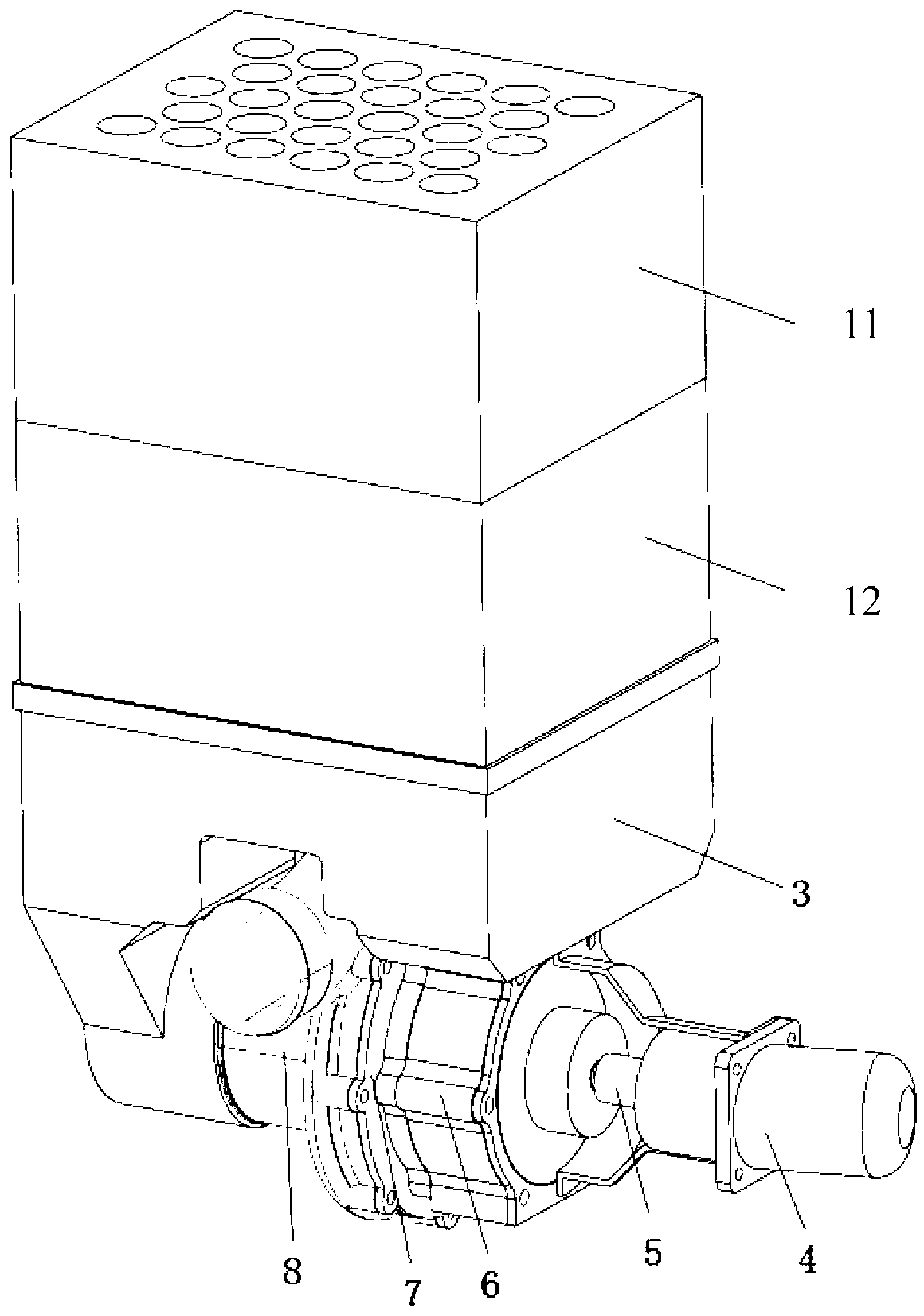

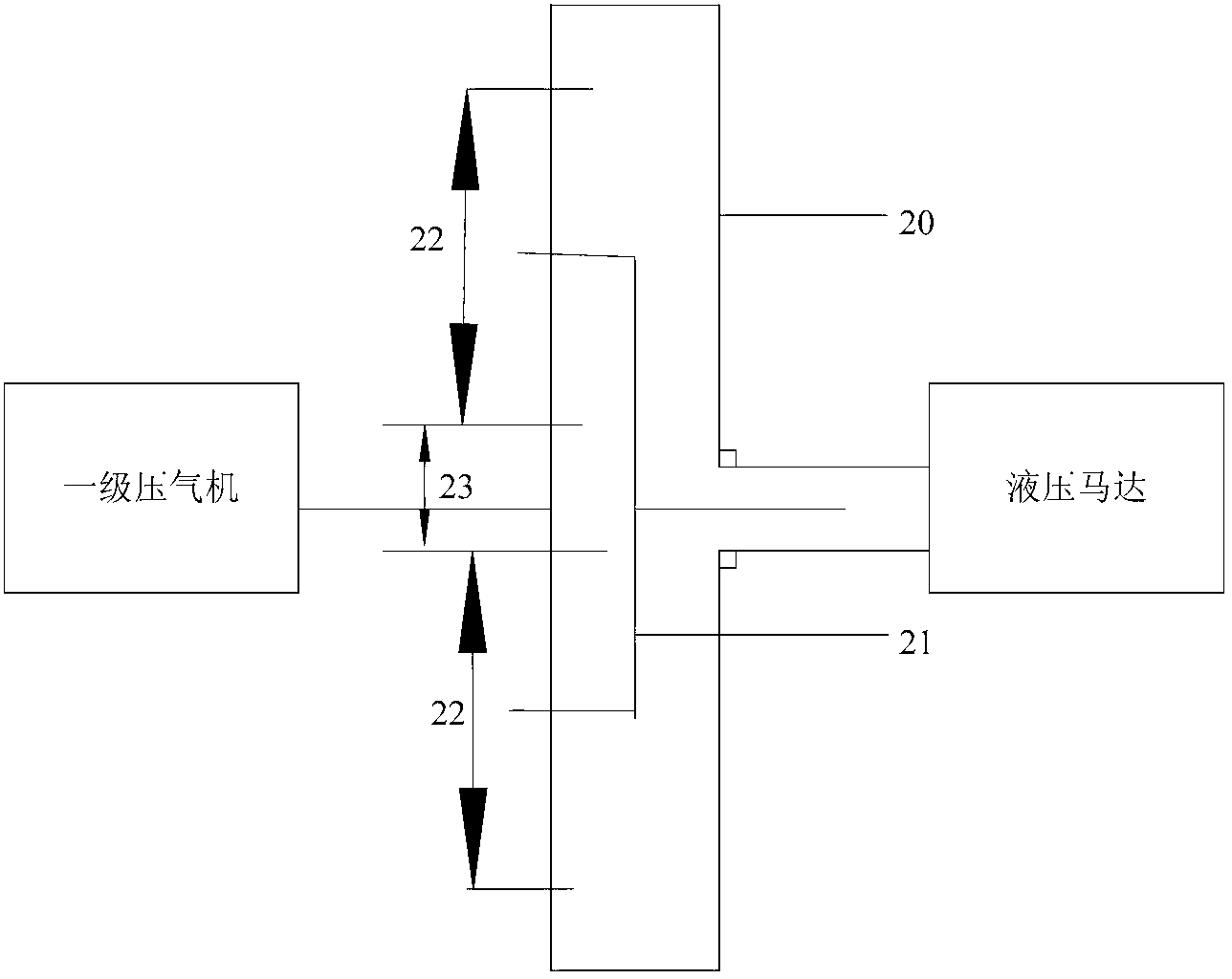

[0042] The first stage is an adjustable supercharger, and the adjustable supercharger includes a primary compressor 8, an intake bypass valve 2, a speed increasing mechanism 6, a driving device and an electronic control system 15; the primary compressor 8 is connected in parallel with the intake bypass valve 2, the primary compressor 8 is connected with the speed-up mechanism 6, the speed-up mechanism 6 is connected with the driving device, and the driving device i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com