Working and abrasion state on-line detection method for shield hob

A wear state and detection method technology, which is applied to measuring devices, devices and instruments that measure the time required to move a certain distance, etc., can solve the problems of complex detection devices or methods, affecting the accuracy of real-time monitoring, etc., and achieve a simple and convenient detection method. Easy to operate, ensure smooth progress, and ensure the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

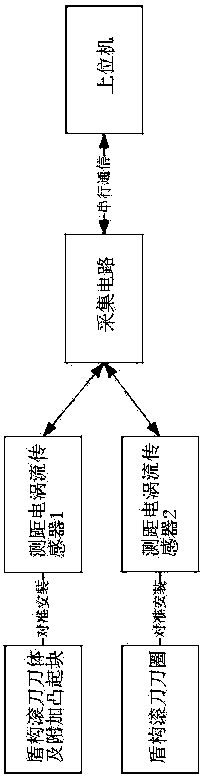

[0020] As attached figure 1 The shown shield hob motion state and wear online detection device consists of two eddy current sensors, a collection circuit and a host computer. Among them, a distance measuring eddy current sensor needs to be installed on the cutter body aligned with the shield hob, and Weld two symmetrical cemented carbide bumps on the cutter body; align the other ranging eddy current sensor at the cutter ring of the hob. The eddy current sensor aligned with the cutter body of the shield hob is used to measure the speed of the hob by distance measurement and the time of two bulges; the eddy current sensor aligned with the hob ring is used to measure the distance Change, judge the wear status of the hob. Among them, the acquisition circuit is a 4-20mA transfer serial port acquisition module.

[0021] The specific detection process is as follows:

[0022] First, the hob is used to measure the current and distance curve of the sensor for measuring the tool wear, reco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com