Slag micropowder grinding system and technology

A slag micropowder and grinding technology, applied in grain processing and other directions, can solve the problems of many mechanical and technological operation failures, limited application scope and high production cost, and achieve convenient system operation, ensure work efficiency, and the shape of micropowder finished products is good. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

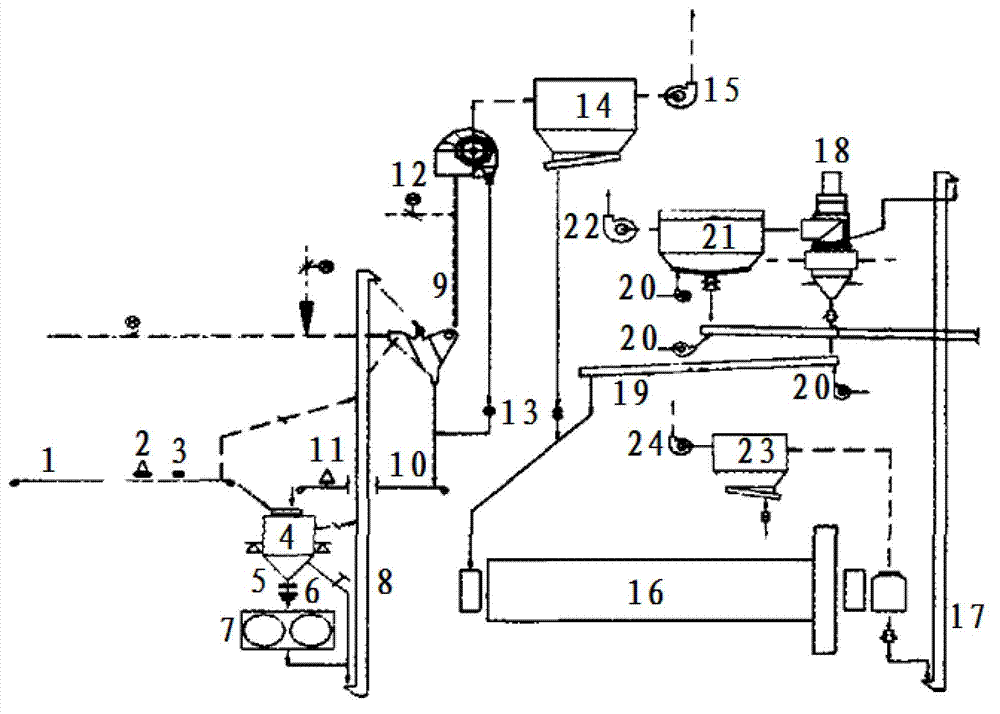

[0022] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings and through specific embodiments:

[0023] Please refer to figure 1 , The present invention provides a slag powder grinding system, which is composed of a roller press 7, an air classifier 9, a dynamic classifier 12, a ball mill 16 and a high-efficiency classifier 18.

[0024] Please refer to figure 1 , the cake elevator 8 is arranged between the roller press 7 and the air classifier 9, the output end of the air classifier 8 is connected with the dynamic classifier 12, and the dynamic classifier 12 is connected with the A first air box pulse bag dust collector 14 is arranged between the ball mills 16 , and an elevator 17 is arranged at the output end of the ball mill 16 , and the elevator 17 is connected to the high-efficiency powder separator 18 .

[0025] Please refer to figure 1 , the slag fine powder grinding system also includes a belt conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com