Cutting device for paper fireworks roll

A cutting device and paper tube technology, applied in metal processing and other directions, can solve the problems of operator cuts, dangerous pushing methods, low work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

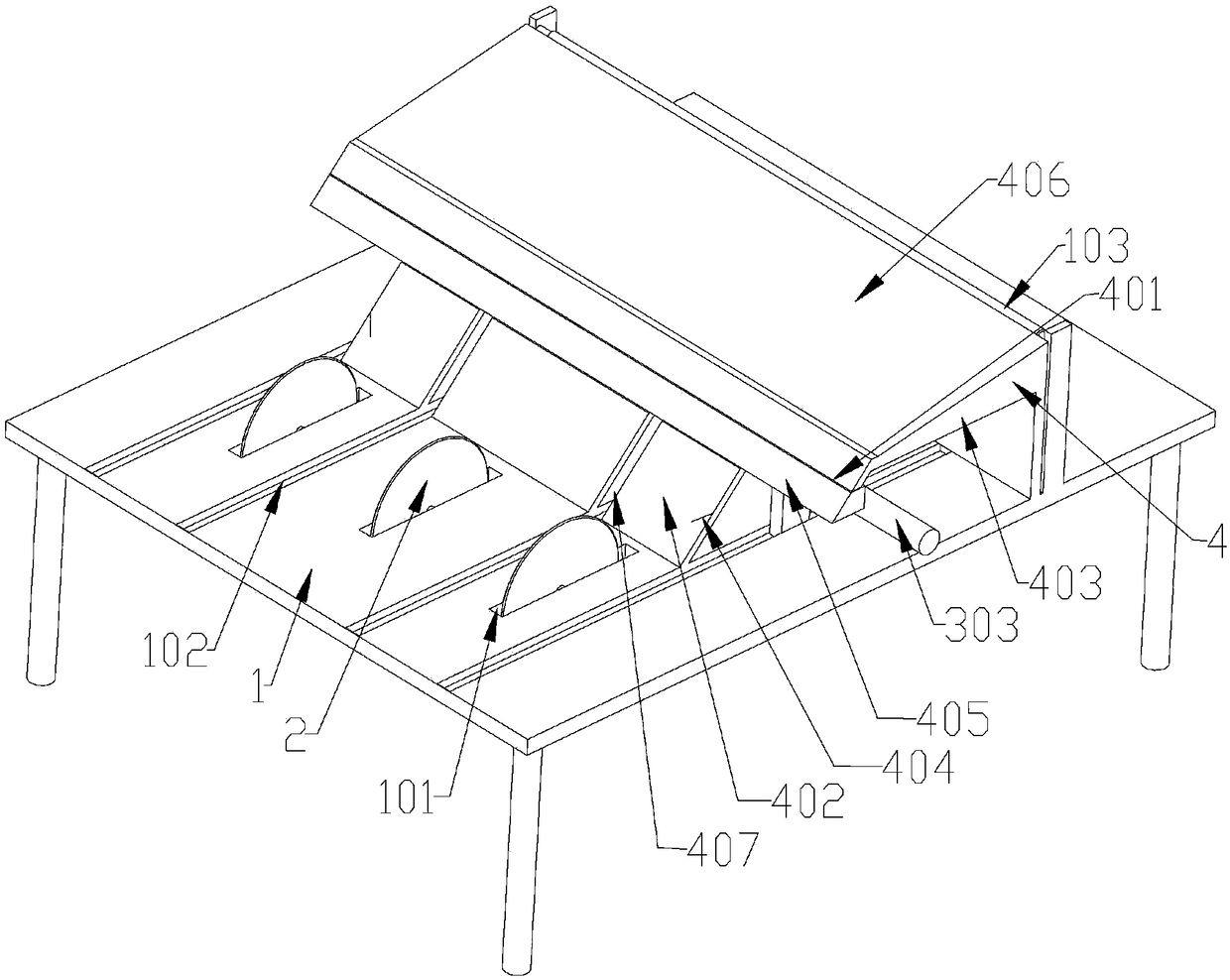

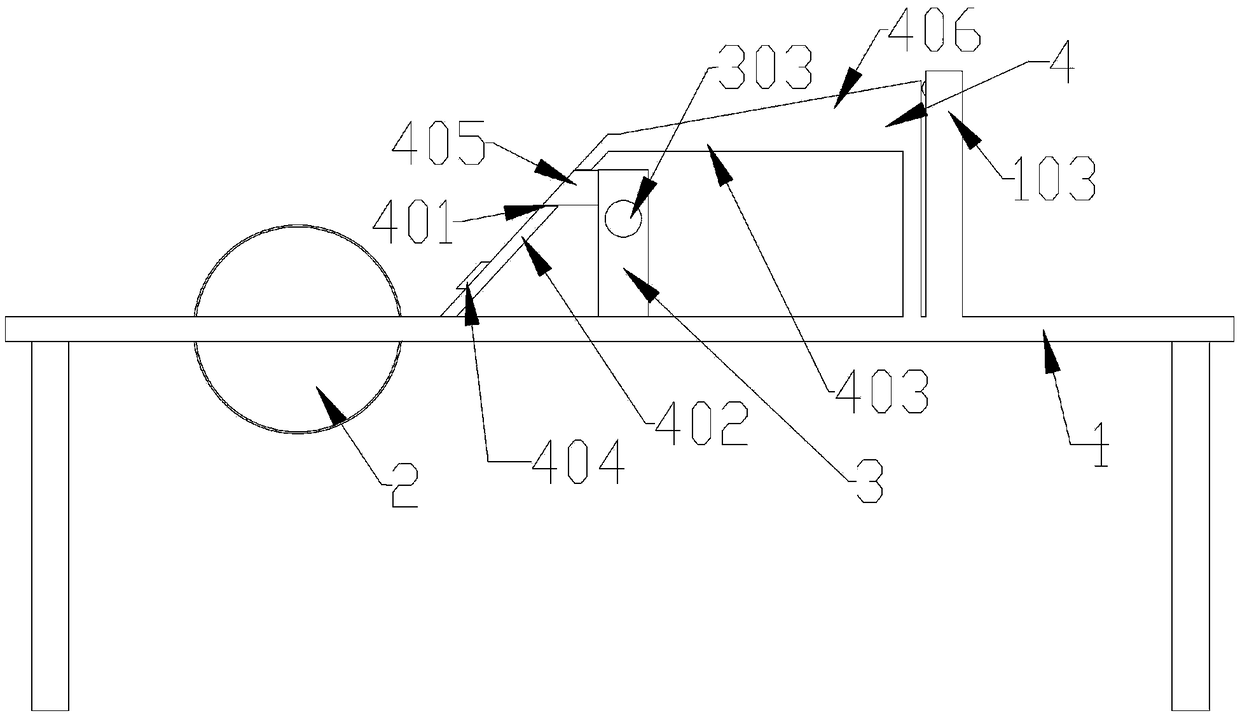

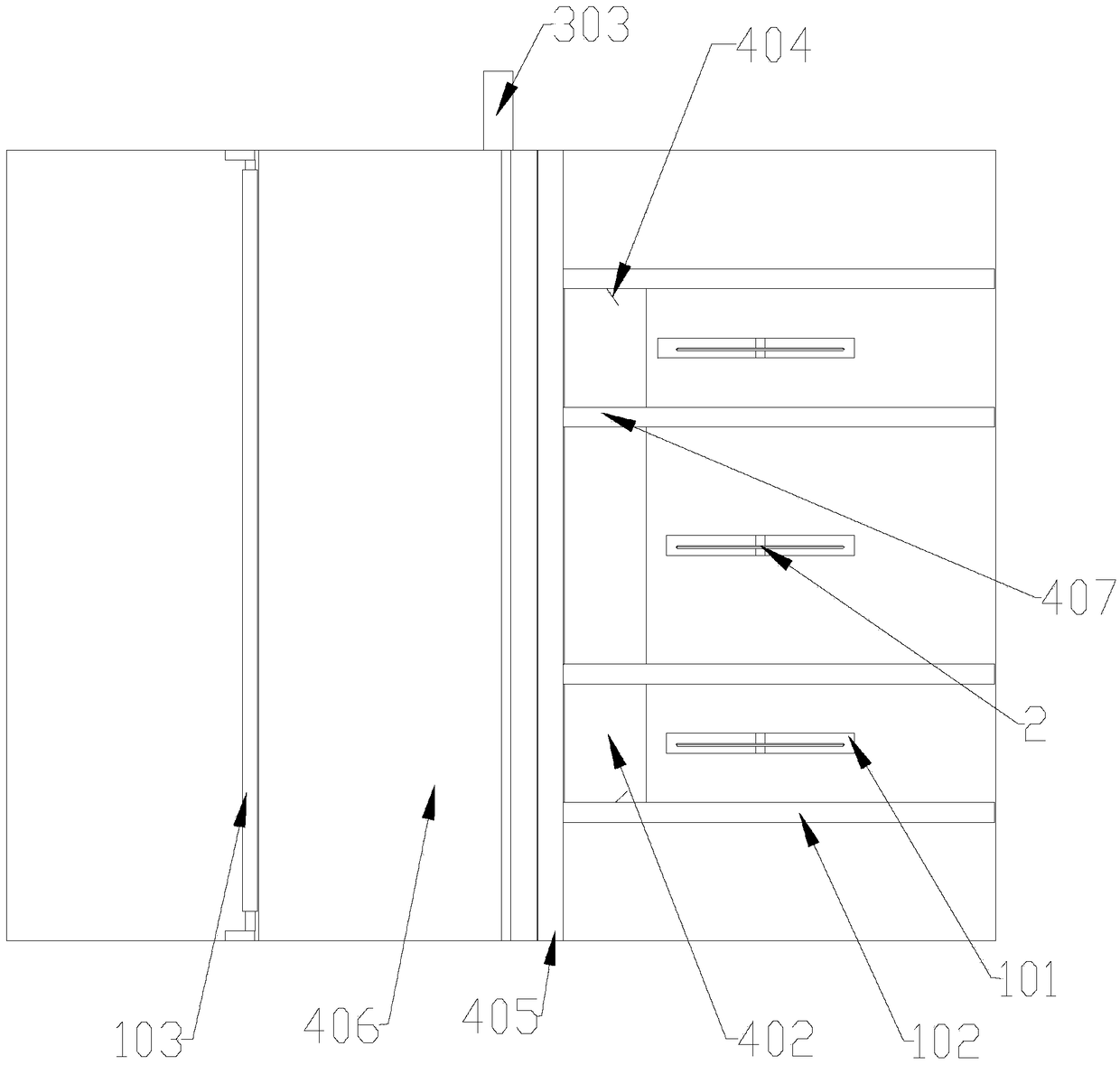

[0021] Embodiment 1: see figure 1 , figure 2 , image 3 , Figure 4 , the applicant has added a pushing mechanism and a firework paper tube to roll down by itself on the traditional cutting device. One side of the bevel structure continuously decreases towards the second guide plate side, so the fireworks paper tube will roll to the second guide plate along the inclined direction of the fourth guide plate under the action of gravity, and when the firework paper tube rolls to After the second guide plate, the fireworks paper tube will roll along the structure of the second guide plate to the second through hole between the first guide plate and the second guide plate. The plate will just fill the second through hole, so the fireworks paper tube will not collide or have a large angular displacement when rolling through the second through hole, and the firework paper tube will roll after rolling through the fourth guide plate in the first through hole. Insert the first guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com