Material splitting barrel

A barrel and barrel separation technology, which is applied in the field of material screening equipment, can solve the problems of heavy labor, low efficiency, and low degree of mechanization, and achieve the effect of accelerating the rolling speed and improving the screening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

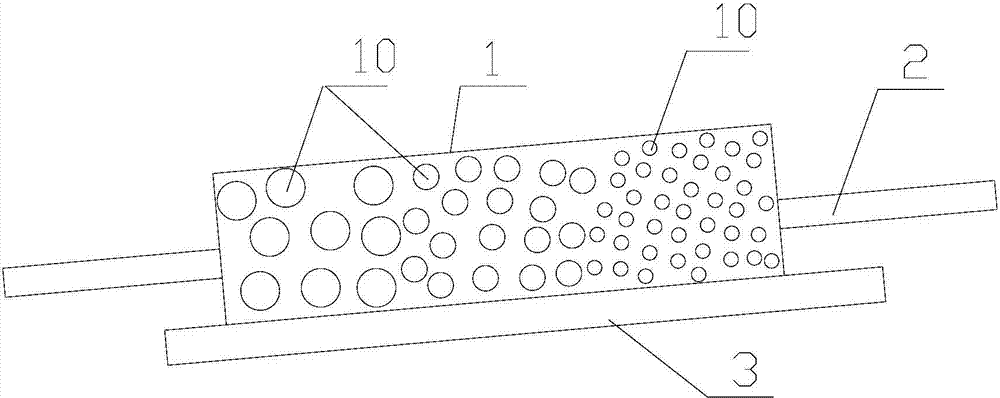

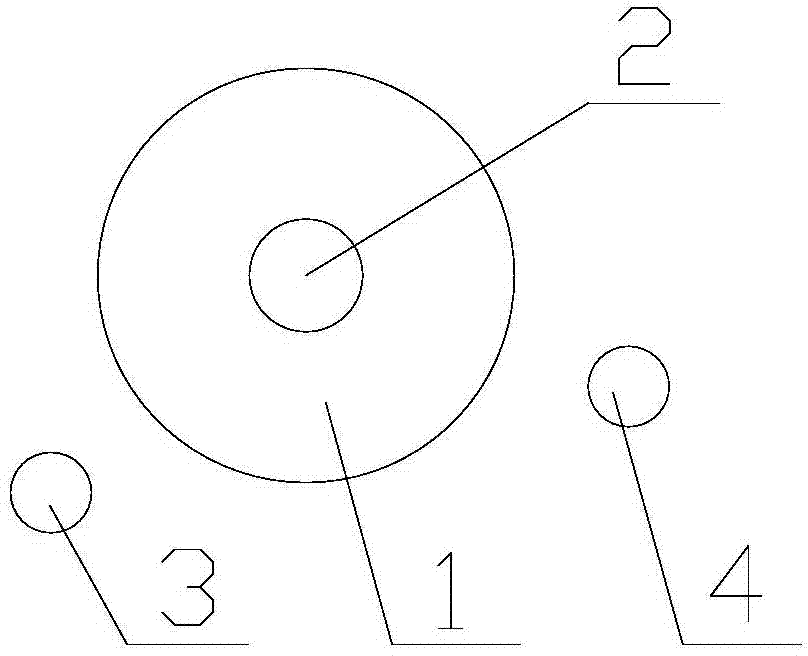

[0016] refer to figure 1 , figure 2 , a distribution cylinder proposed by the present invention includes a cylinder body 1, a bracket 2, a first brush rod 3, a second brush rod 4 and a driving mechanism.

[0017] The cylinder body 1 is mounted on the bracket 2 so as to be rotatable around the central axis and is arranged obliquely. The surrounding wall of the cylinder body 1 is provided with a plurality of sieve holes 10 distributed from small to large in diameter from the high end to the low end. Specifically, it can be understood that the cylinder body 1 is formed by sequentially connecting N sections of integrally formed sub-cylinders. In this embodiment, N=3, and the sieve holes 10 on each sub-tube have different aperture diameters, and the first sub-cylinder is located at the high end. , the third sub-cylinder is located at the lower end, and from the first sub-cylinder to the third sub-cylinder, and from the first sub-cylinder to the third sub-cylinder, the diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

| Slope | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com