Impurity separating equipment for soft sheet material

A technology of separation equipment and flakes, applied in the direction of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., can solve problems such as low separation rate, air pollution, and limited centrifugal separation effect, and achieve improved separation efficiency, improve the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

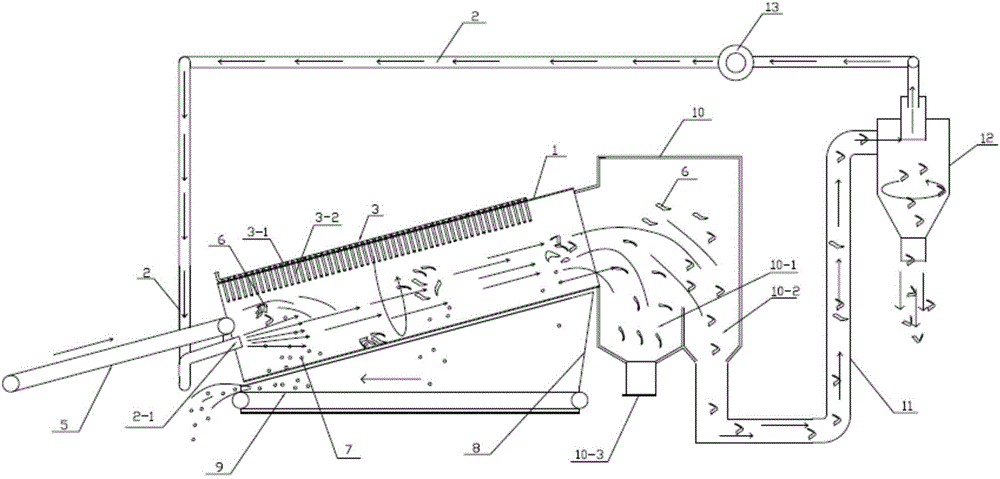

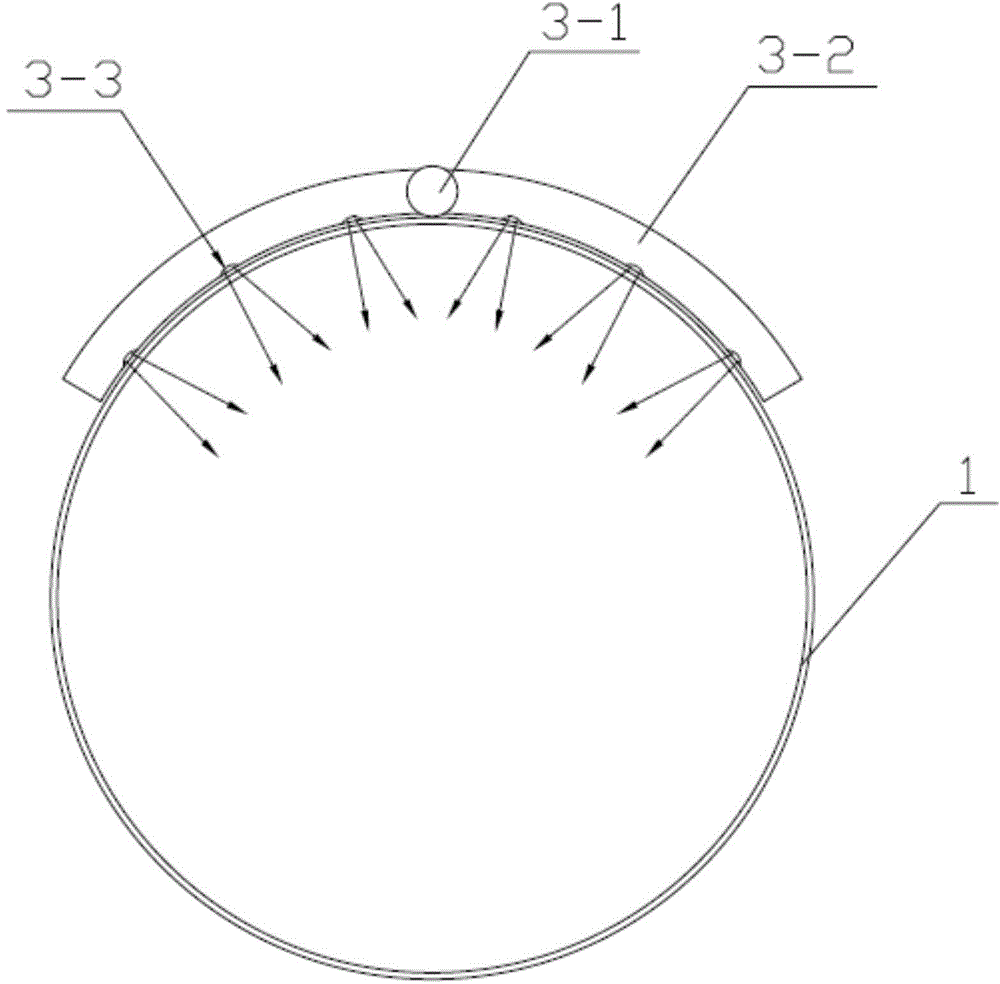

[0049] see figure 1 , The impurity separation equipment for soft flake materials in this embodiment includes an air supply device, a separation cylinder 1, a separation cylinder driving device for driving the separation cylinder 1 to rotate, a feeding mechanism, a secondary separation device for soft flakes, and a gas separation device for soft flakes. Wherein, the air supply device includes a fan and an air duct 2 connected with the fan. The wall of the separating cylinder 1 is provided with screen holes, and the two ends of the separating cylinder 1 are open, wherein the opening at one end is the feeding end, and the opening at the other end is the discharging end; the air outlet of the air duct 2 2-1 is set at the feeding end of the separation cylinder 1. The driving device of the separation cylinder 1 is composed of a ring gear arranged on the outer wall of the separation cylinder 1, a driving gear meshed with the ring gear and a motor connected with the driving gear. Th...

Embodiment 2

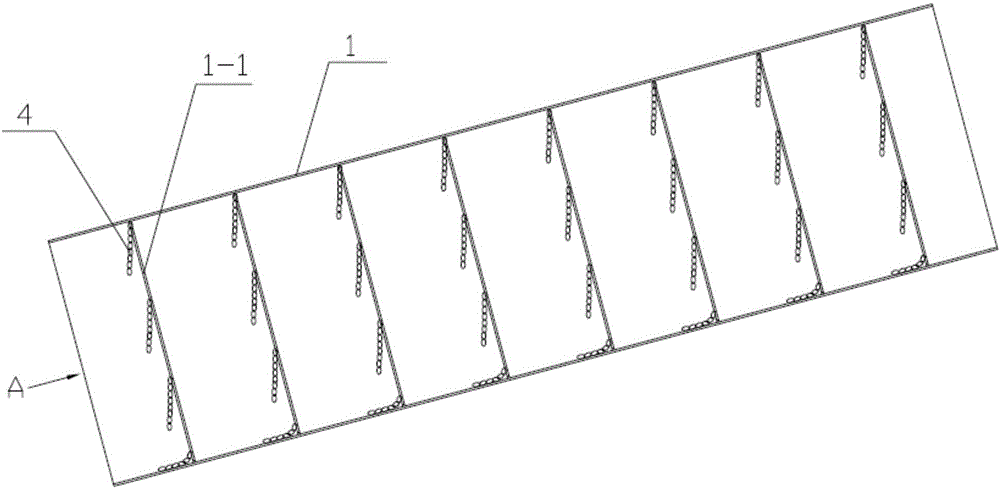

[0060] See 3~ Figure 5 In this embodiment, a hanging chain 4 is installed in the inner wall of the separation cylinder 1 to replace the pulse air flow device 3 in the embodiment 1, so as to prevent the clogging of the screen holes and improve the separation effect. The chains 4 provided on the inner wall of the separation cylinder 1 are multiple groups, the chains 4 are metal chains, and the multiple groups of chains 4 are distributed along the axial direction of the separation cylinder 1, and each group of chains 4 includes A plurality of hanging chains 4 distributed in the circumferential direction. Its working principle is: when the separation cylinder 1 is in a static state, the hanging chain 4 located at the upper part of the separation cylinder 1 hangs down naturally, and the hanging chain 4 at the bottom of the separation cylinder 1 lies on the separation cylinder 1; the separation cylinder 1 continuously Rotation, in the process of the separation drum 1 rotating one ...

Embodiment 3

[0065] see Figure 6 , In this embodiment, the pulse air flow device 3 in embodiment 1 and the chain 4 in embodiment 2 are used at the same time to better prevent the clogging of the screen hole and improve the separation effect.

[0066] Embodiments other than the above in this embodiment are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com