Forced circulating and crystallizing device for industrial wastewater treatment

A technology of forced circulation crystallization and forced circulation, applied in the direction of heating water/sewage treatment, etc., can solve the problems of inability to obtain high-quality distillate, compressor shutdown, compressor vibration, etc., to avoid blockage, reduce equipment cleaning, improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

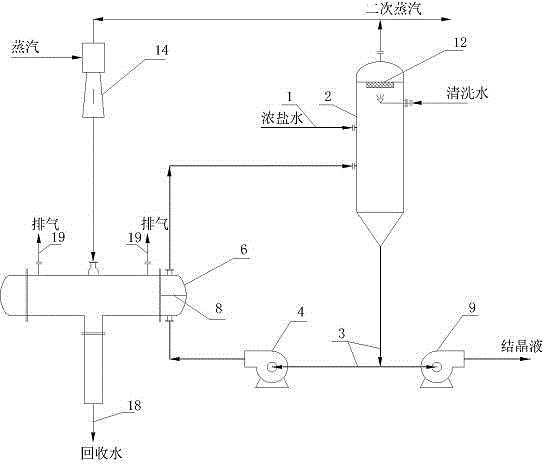

[0011] see figure 1 , the present invention includes a crystallizer 2 and a horizontal double-tube forced circulation heat exchanger 6 . The shell side wall of the crystallizer 2 is provided with a feed inlet 1, and the bottom of the crystallizer 2 is connected with a discharge pipe 3. The concentrated brine coming out of the discharge pipe 3 returns to the crystallizer 2 through the circulation pump 4 and the forced circulation heat exchanger 6 in sequence. The steam in the crystallizer 2 is drawn out from the top of the crystallizer 2 by an external thermal compressor 14 after passing through the demister 12 and enters the forced circulation heat exchanger 6 to heat and concentrate the concentrated brine. The demister 12 has two stages, the first stage adopts corrugated plate vertical flow equipment, and the second stage adopts wire mesh type equipment. The forced circulation heat exchanger 6 is provided with a horizontal partition 8, so that the concentrated brine enterin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com