Screening device for construction waste treatment

A construction waste and screening device technology, which is applied in sieve, magnetic separation, solid separation and other directions, can solve the problems of difficult separation of metal materials and non-metal materials, low efficiency, and single function of construction waste treatment devices. Achieve the effect of no dead point in motion, small footprint and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

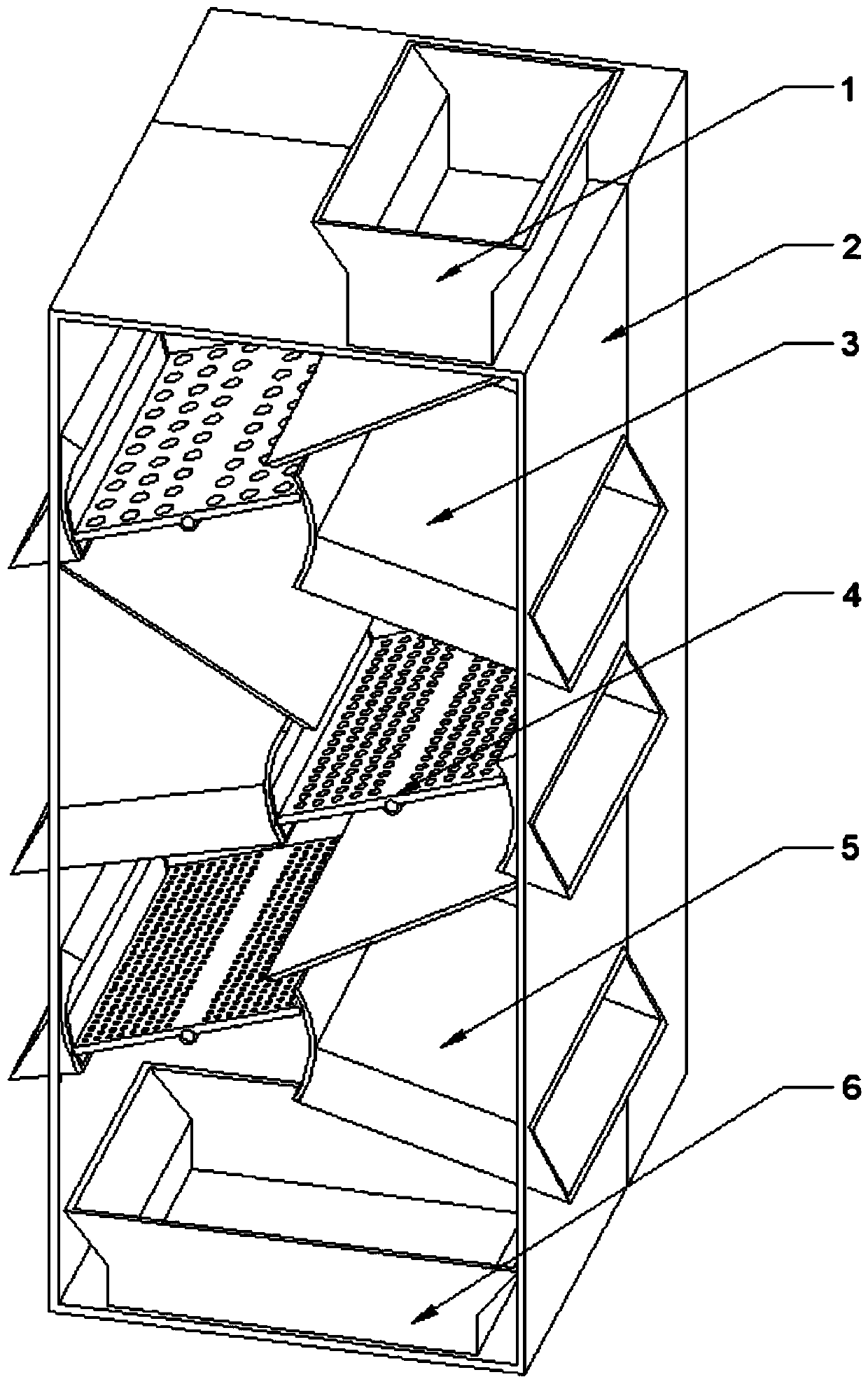

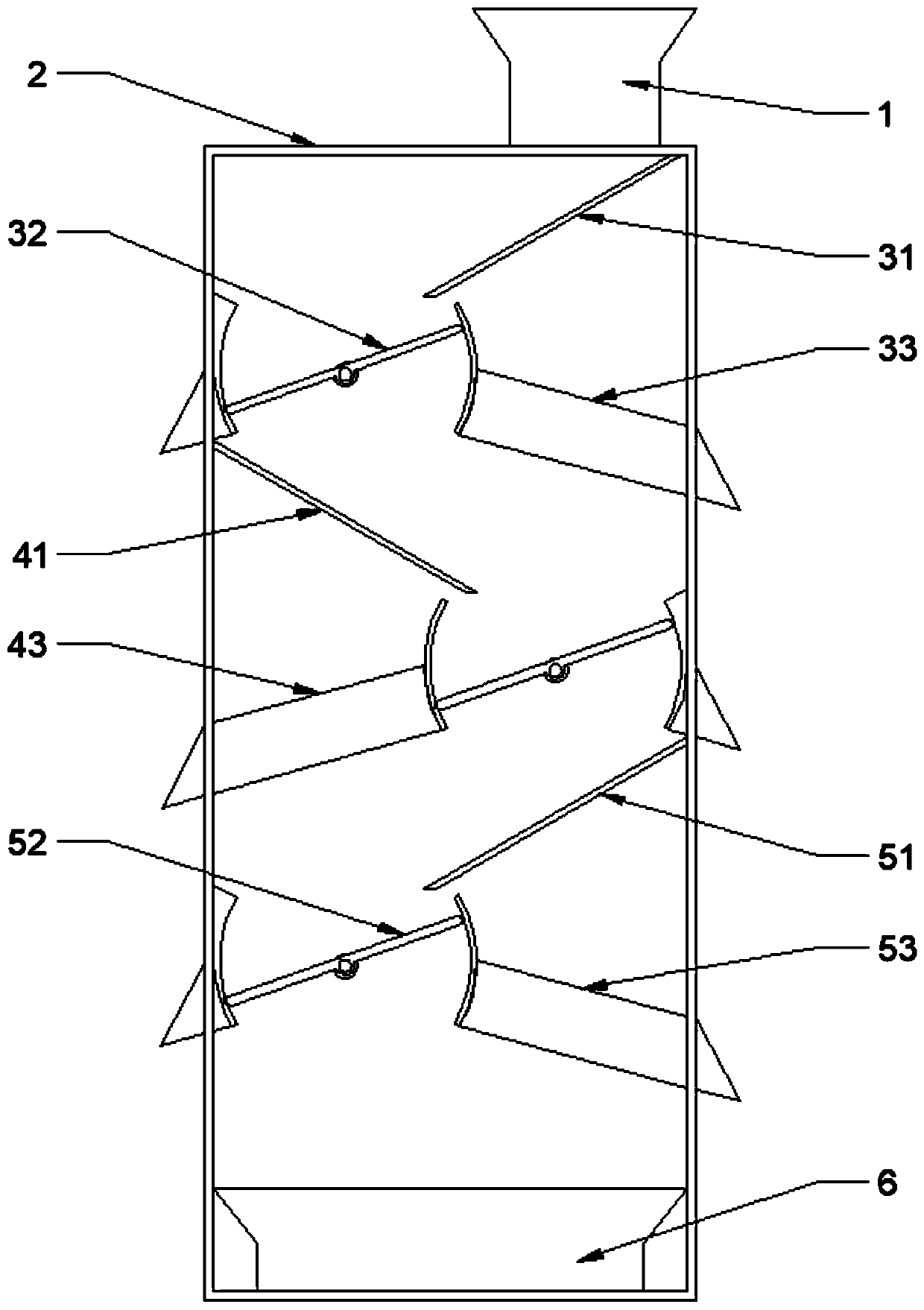

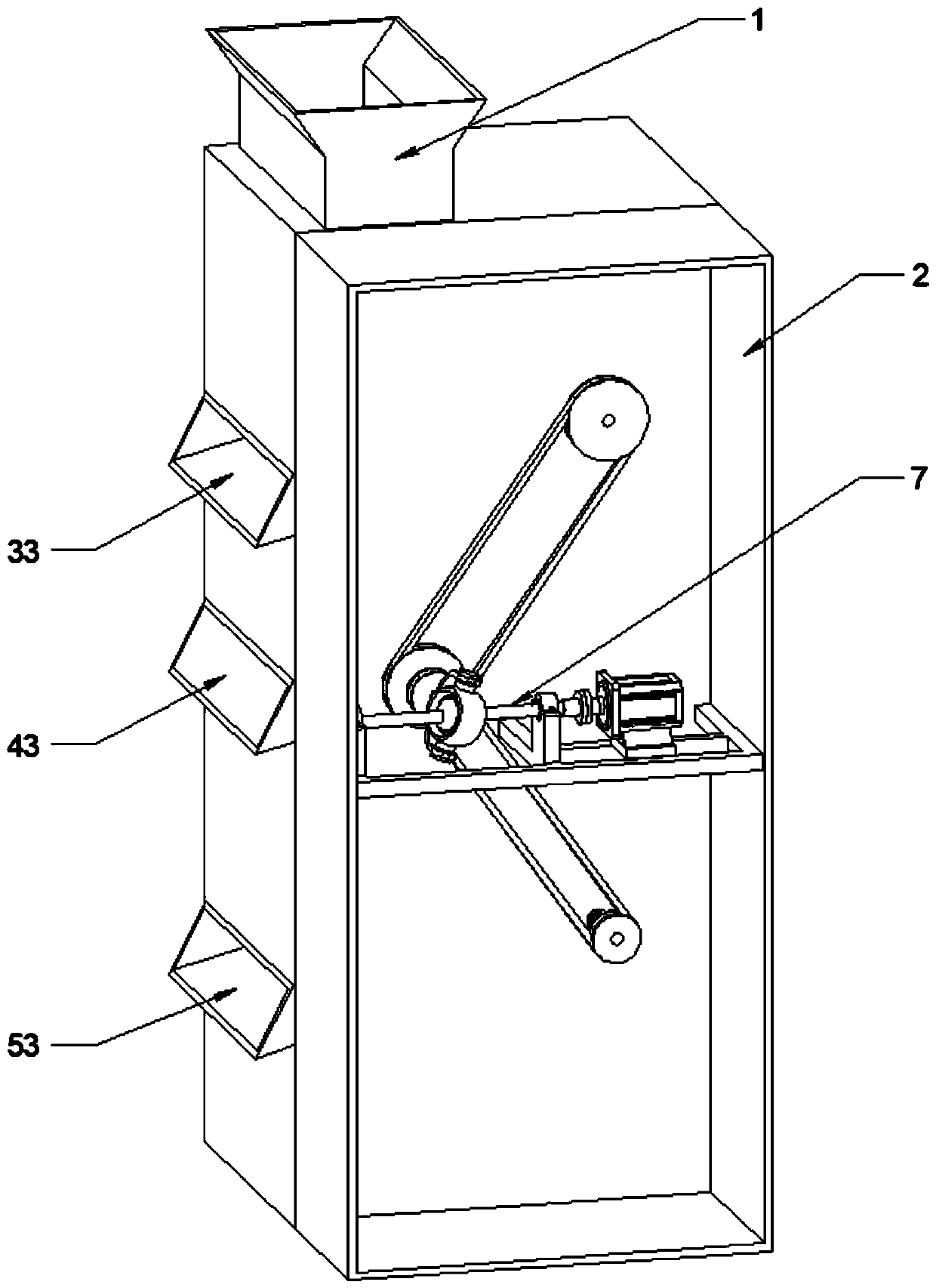

[0028] see Figure 1~5 , in an embodiment of the present invention, a screening device for construction waste treatment, including a box body 2 and a screening mechanism arranged inside the box body 2, a feeding hopper 1 is provided on one side of the top of the box body 2, and the box body 2 One side of the bottom of the body 2 is provided with a discharge hopper 6, the material enters the inside of the box body 2 from the feed hopper 1, is screened, and then discharged from the discharge hopper 6, and the screening mechanism is rotated by a driving mechanism 7, and the driving mechanism 7 An eccentric shaft 75 is arranged inside, and the eccentric shaft 75 is fixedly connected with the screening mechanism. By driving the eccentric shaft 75 to swing back and forth, the screening mechanism is driven to swing back and forth to achieve the purpose of screening.

[0029] The screening mechanism includes a first screening mechanism 3, a second screening mechanism 4 and a third scr...

Embodiment 2

[0035] see Figure 1~6 , in the embodiment of the present invention, a screening device for construction waste treatment, on the basis of the box body 2 of the embodiment, a discharge permanent magnet 8 is added, which is arranged obliquely above the discharge hopper 6 and below the third screening mechanism 5, It forms an angle of 30° with the horizontal direction. After three-stage screening, the fine materials that meet the minimum sieve hole diameter fall, and after further adsorption by the discharge permanent magnet 8, the small particles of metal in the fine materials are adsorbed, and the small particles of non-metal The material is discharged from the hopper 6 to improve the separation effect of metal.

[0036] The working principle of the present invention is:

[0037] During work, start the motor 74, drive the eccentric shaft 75 to do circular motion through the motor 74, and drive the swing rod 73 to swing back and forth through the swing collar 76, and simultaneo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com