Separation equipment for Fischer-Tropsch slurry bed reactor products

A separation equipment, slurry bed technology, applied in separation methods, dispersed particle separation, and cyclone axial reversal devices, etc. quality and other issues, to avoid entrainment of heavy components, prevent clogging, and meet production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is described in further detail below:

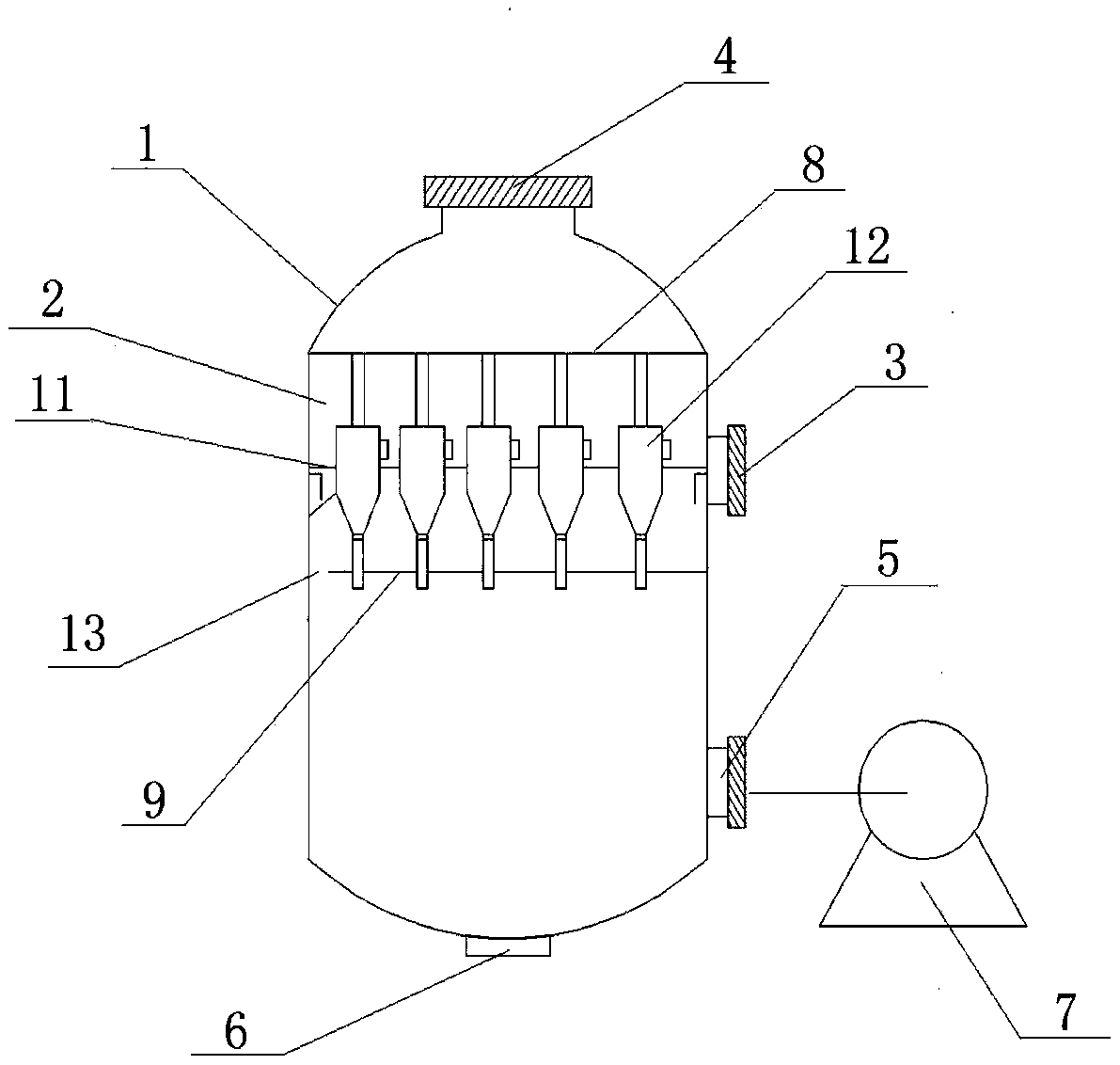

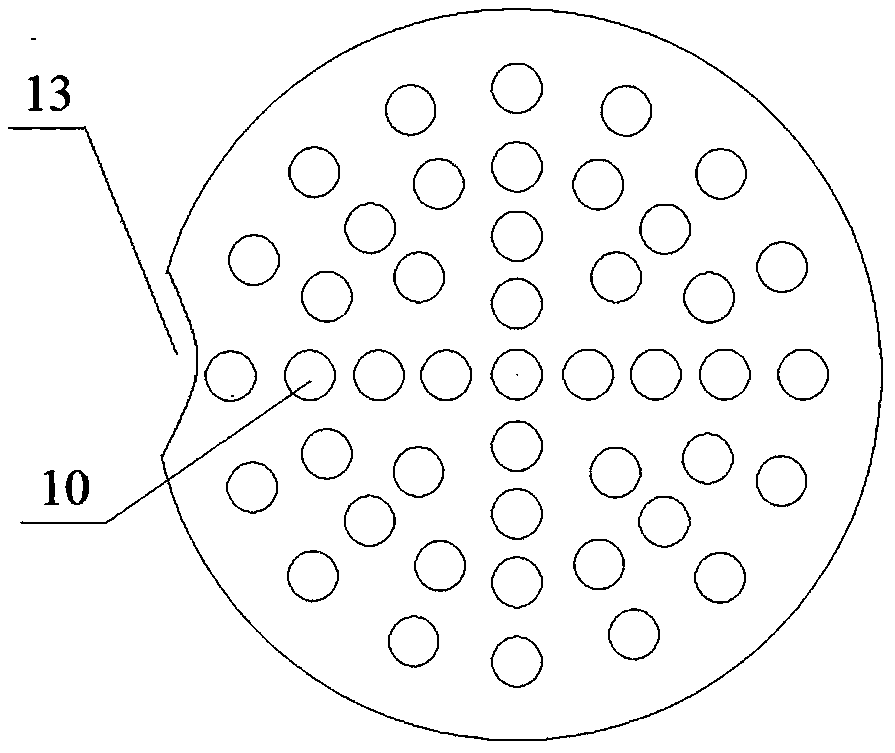

[0030] Such as figure 1 As shown, the separation equipment of the Fischer-Tropsch slurry bed reactor product includes a shell 1 and a cyclone separator group 2; the shell 1 includes a shell cavity, and the side wall of the shell 1 is provided with a mixed liquid feed port 3, and the cyclone separator Group 2 consists of several such as image 3 The shown cyclone separator 12 is located in the inner cavity of the housing.

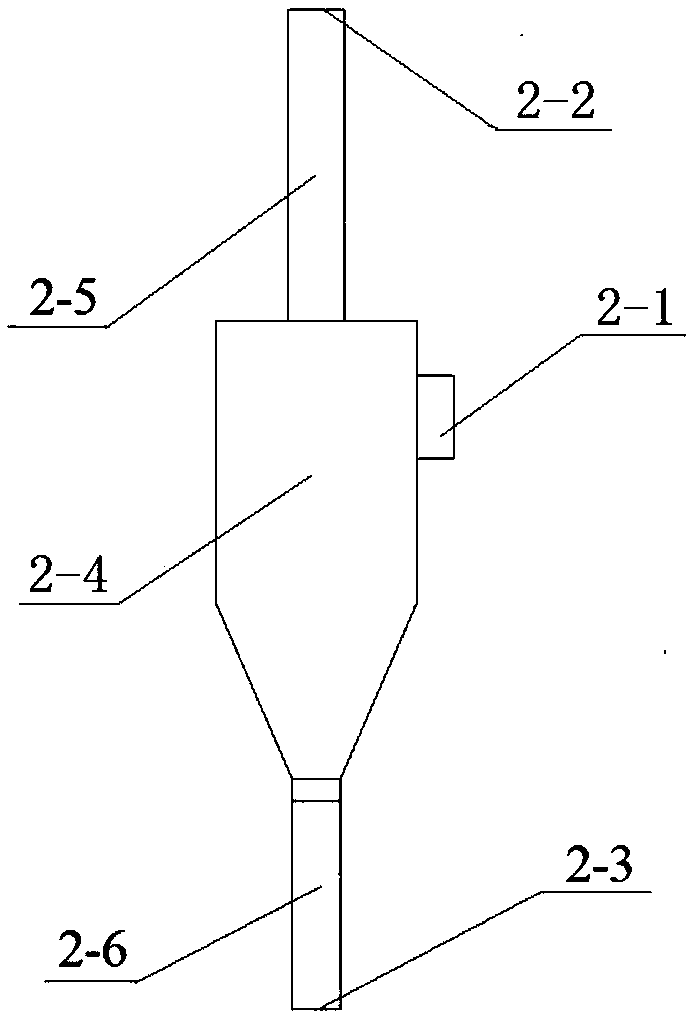

[0031] The reaction product of the Fischer-Tropsch slurry bed is transported to the feed port 2-1 of the cyclone separator 12 by the mixed liquid feed port 3, as image 3 As shown, the cyclone separator 12 is composed of three parts: the separation chamber 2-4, the gas riser 2-5 and the liquid downcomer 2-6. The feed inlet 2-1, the upper end outlet of the separation chamber 2-4 are connected with a gas riser 2-5, and the top of the gas riser 2-5 is provided with a gas phase component out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com