Scrap iron pressing device of machining center

A technology of a pressing device and a machining center, which is applied to metal processing equipment, metal processing machinery parts, presses, etc., can solve the problems of small amount of manual intervention, increased labor intensity, and pollution of occupied space, so as to improve environmental quality and save The effect of manipulating the space and improving the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

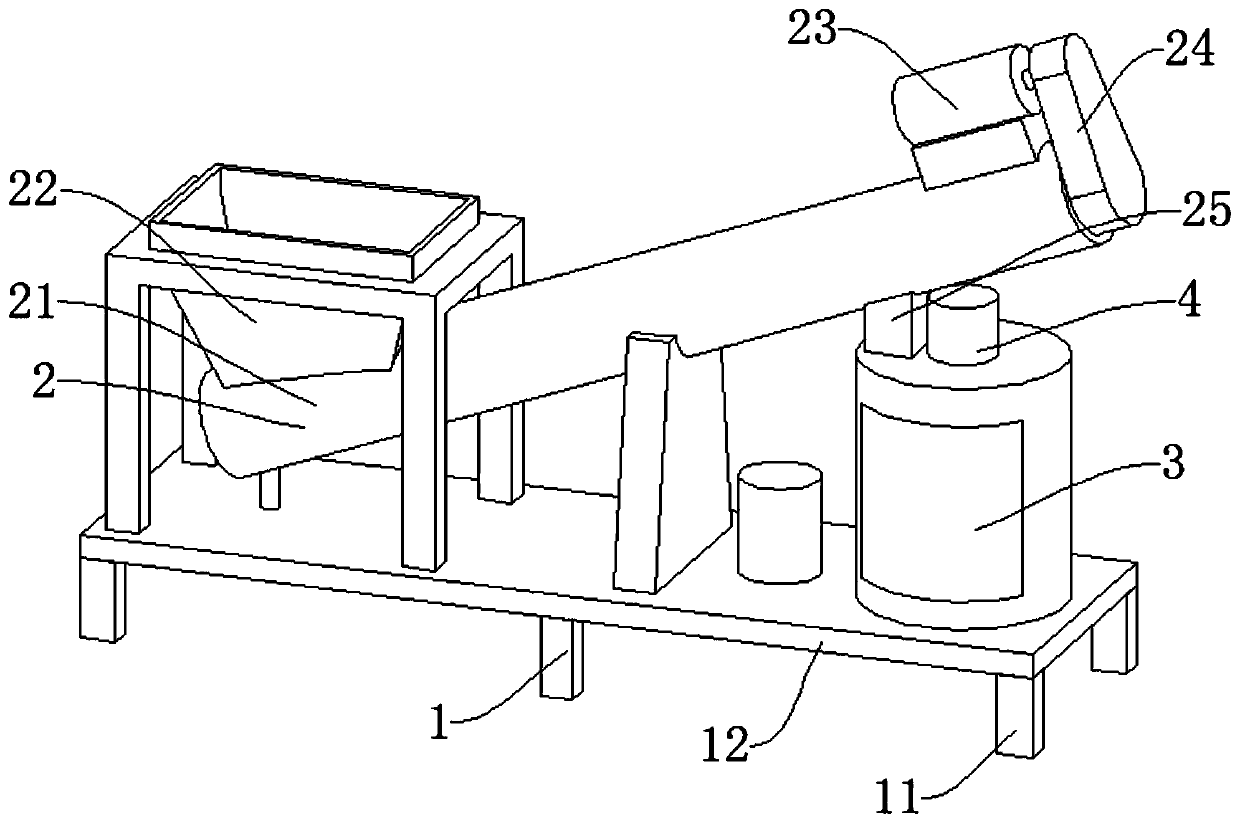

[0040] like Figure 1-Figure 3 , Figure 5-Figure 7 As shown, a chip pressing device of a machining center includes a feeding device 2 arranged above the supporting device 1, a rotating device 3 arranged on one side of the feeding device 2, and a compression device arranged inside the rotating device 3 Institution 4.

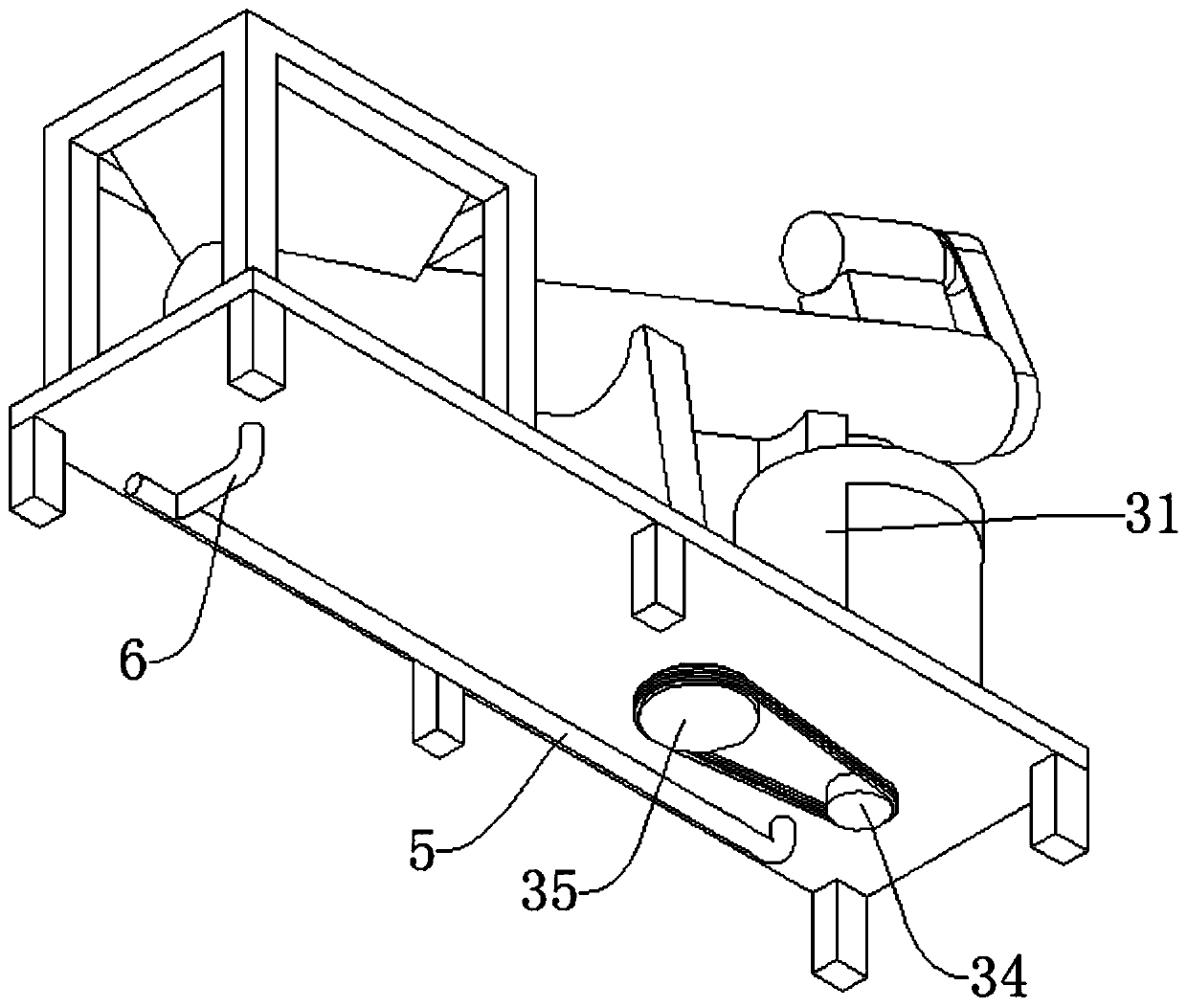

[0041]Preferably: the rotating device 3 includes an outer cylinder 31, the outer cylinder 31 is connected with the support device 1, an inner cylinder 32 is arranged inside the outer cylinder 31, a transmission shaft 33 is connected to the lower end of the inner cylinder 32, and a small pulley 34 is connected to the lower end of the transmission shaft 33 One side of the small pulley 34 is provided with a large pulley 35, the large pulley 35 is connected to the output end of the second servo motor 36, and the second servo motor 36 provides rotational power for the inner cylinder 32, so that the iron entering the inner cylinder 32 Chips rotate at a high speed in...

Embodiment 2

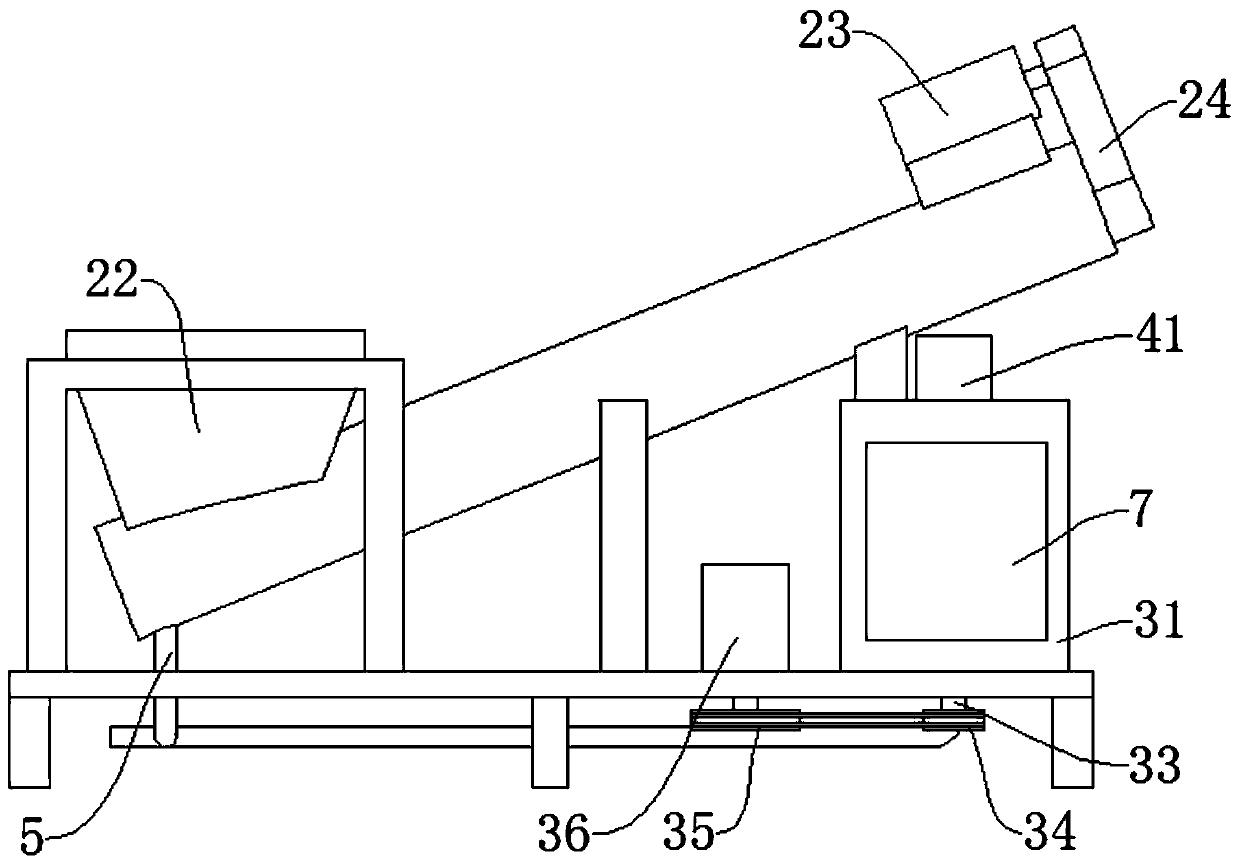

[0043] like Figure 4 , Image 6 , Figure 7 As shown, a chip pressing device of a machining center includes a feeding device 2 arranged above the supporting device 1, a rotating device 3 arranged on one side of the feeding device 2, and a compression device arranged inside the rotating device 3 Institution 4.

[0044] Preferably: the rotating device 3 includes an outer cylinder 31, the outer cylinder 31 is connected to the supporting device 1, the inner cylinder 32 is provided inside the outer cylinder 31, the lower end of the inner cylinder 32 is provided with a rotating groove through which the lower hydraulic cylinder 47 passes, and the lower end of the inner cylinder 32 is connected to Transmission shaft 33 is arranged, and transmission shaft 33 lower ends are connected with small belt pulley 34, and small belt pulley 34 side is provided with large belt pulley 35, and large belt pulley 35 is connected on the second servomotor 36 output ends, passes through second servom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com