Adjustable cyclone separator

The technology of a cyclone separator and a cyclone cylinder is applied in the direction of a cyclone device, a device in which the axial direction of the cyclone can be reversed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

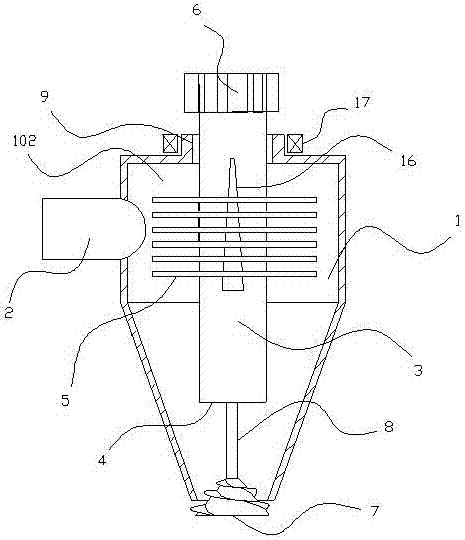

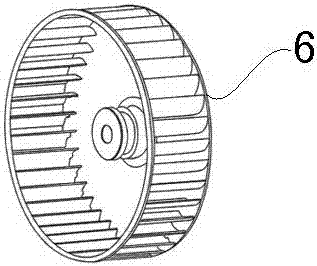

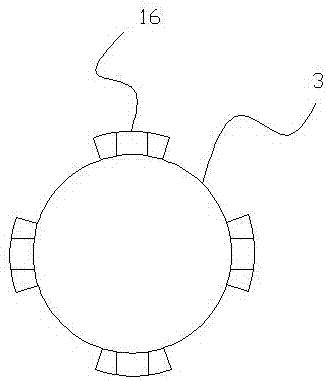

[0024] Such as figure 1 , 2 , As shown in 3 and 4, an adjustable cyclone separator includes a cyclone cylinder body 1, an air inlet pipe 2, an exhaust pipe 3, and a lower port 4 of the cyclone cylinder body composed of a cylindrical chamber and a conical chamber Unicom. The exhaust pipe is rotatably matched with the cyclone cylinder, for example, the two can be matched in a gap. The exhaust pipe is covered with a plurality of discs 5 that can move freely along the exhaust pipe axis. A trapezoidal bump 16 with a small top and a big bottom is arranged in the axial direction, and the disc is provided with a gap 501 that matches the bump. , there is a certain distance between the discs, and the discs can move upwards from the locking point. The discs are soft iron sheets, and an electromagnet 17 for attracting the discs is arranged on the cyclone cylinder. There is a space for storing discs in the upper cyclone cylinder, such as Figure 5 As shown, the discs can be sucked toget...

Embodiment 2

[0028] Such as Figure 6 , 7 As shown, the difference from Embodiment 1 is that in the above-mentioned adjustable cyclone separator, the upper end of the exhaust pipe extends into the transverse air duct 10, and a control exhaust pipe is arranged between the upper end of the exhaust pipe and the transverse air duct. The centrifugal lifting control mechanism for air pipe lifting. The centrifugal lifting control mechanism includes a connecting rod connected between the upper end of the exhaust pipe and the horizontal air guide pipe. The connecting rod is equipped with a flying ball. The structural principle is the same as that of the Watt governor (or called Flying ball governor) is the same, that is, a rotating shaft 11 is set on the transverse air duct, the rotating shaft and the upper end of the exhaust pipe are directly connected with a connecting rod 12, and the hinge connection between the connecting rods is connected with a flying ball 13. When the rotation speed of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com