Preparation method of gold nanoparticle modification based open tubular column

A gold nanoparticle and open-tubular column technology, which is applied to measuring devices, instruments, scientific instruments, etc., to achieve good reproducibility, improve the effect of small open-tubular columns and strong bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of open-tube column for capillary electrochromatography with gold nanoparticles bonded to dodecyl mercaptan:

[0024] (1) Synthesis of gold nanoparticles (reference: Southeast University Journal, 2003, 33(4): 471-474.): Take 100mL of pure water and heat it to 100-120℃, and take 1-2% chlorine 1mL of gold acid aqueous solution, heat and stir for 15-20min, then quickly add 3mL of 1-2% sodium citrate aqueous solution, stir for 30-60min, cool to room temperature, and set aside;

[0025] (2) Pretreatment of capillary tube: 1) 1mol / L HCl rinse for 20-40min; 2) secondary water rinse for 20-40min; 3) 1mol / L NaOH rinse for 15-18h; 4) secondary water rinse for 20-40min; 5) 0.1mol / L HCl rinse for 20-40min; 6) secondary water rinse for 20-40min; 7) acetone rinse for 20-40min; 8) 180℃ N 2 Next, blow dry for 3h.

[0026] (3) Silanization of the capillary: Take a pretreated capillary of appropriate length, inject 10-20vol% tetramethoxysilane in anhydrous toluene solution, and rea...

Embodiment 2

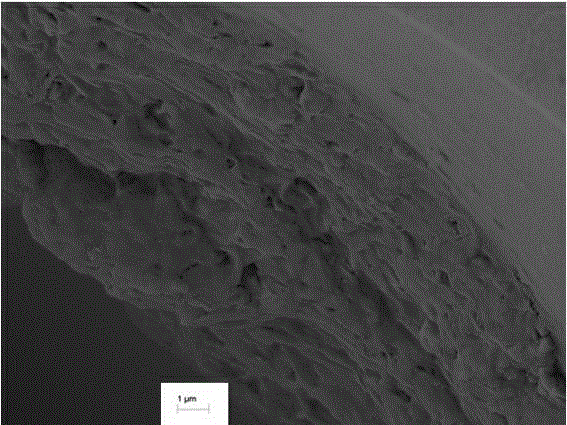

[0029] The transmission electron microscope of the open column of capillary electrochromatography with gold nanoparticles bonded to dodecyl mercaptan is shown as figure 1 Shown.

Embodiment 3

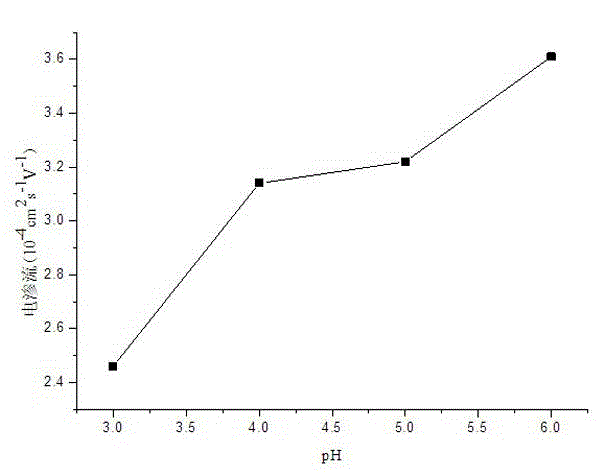

[0031] The electroosmotic flow characteristics of a capillary electrochromatographic open-tube column with gold nanoparticles bonded to dodecyl mercaptan under different pH conditions.

[0032] The electroosmotic flow characteristics of open-tube capillary electrochromatographic columns with gold nanoparticles bonded to dodecyl mercaptan under different pH conditions are as follows figure 2 Shown. The capillary inner diameter of the open column is 50μm, the capillary column length is 60cm (effective length 35cm), phosphate buffer (pH 3.0, 5mmol / L) is the mobile phase, the separation voltage is +15kV, the detection wavelength is 214nm, and thiourea is the electroosmotic flow marker Things.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com