Volatile organic matter condensing device

A volatile organic compound and condensation device technology, which is applied in steam condensation, chemical instruments and methods, separation methods, etc., can solve the problems of large waste water, high moisture content, and must be reprocessed, and achieves improved separation effect, improved recovery quality, Improve the effect of capture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

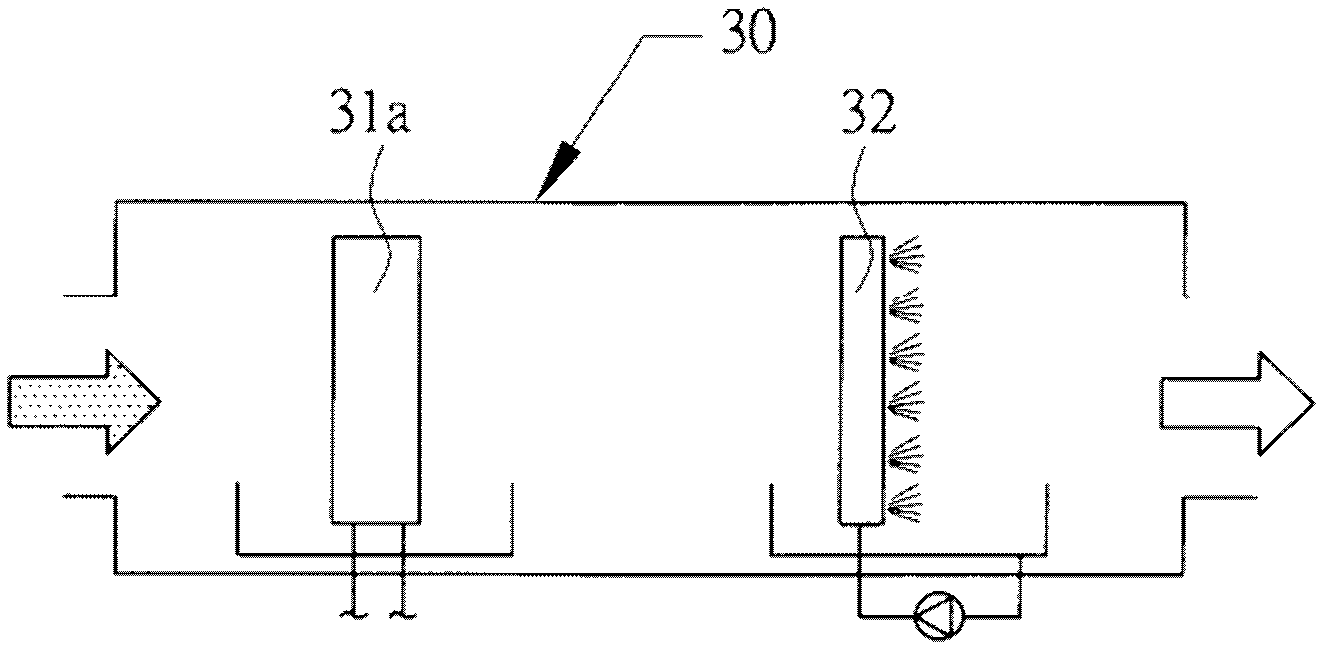

[0046] First, see image 3 As shown, in the first embodiment of the present invention, a first condenser 31a is arranged inside an exhaust gas flow channel 30, and a sprinkler 32 is arranged at the downstream end of the first condenser 31a, and firstly the first condenser 31a separates most of the water-soluble volatile organic compounds, and then the sprinkler 32 sprays water mist on the passing exhaust gas flow, so that the remaining water-soluble volatile organic compounds are separated by the adsorption of water droplets.

[0047] Next, see Figure 4 As shown, the second embodiment of the present invention is further provided with a second condenser 31b at the downstream end of the sprinkler 32, and the first condenser 31a and the second condenser 31b can be condensing coils or plate condensers , a shell-and-tube condenser or a finned condenser; thus, due to the effect of spraying water mist by the sprinkler 32, the exhaust gas flow entering the second condenser 31b is he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com