Positive material for lithium ion battery and its preparation method

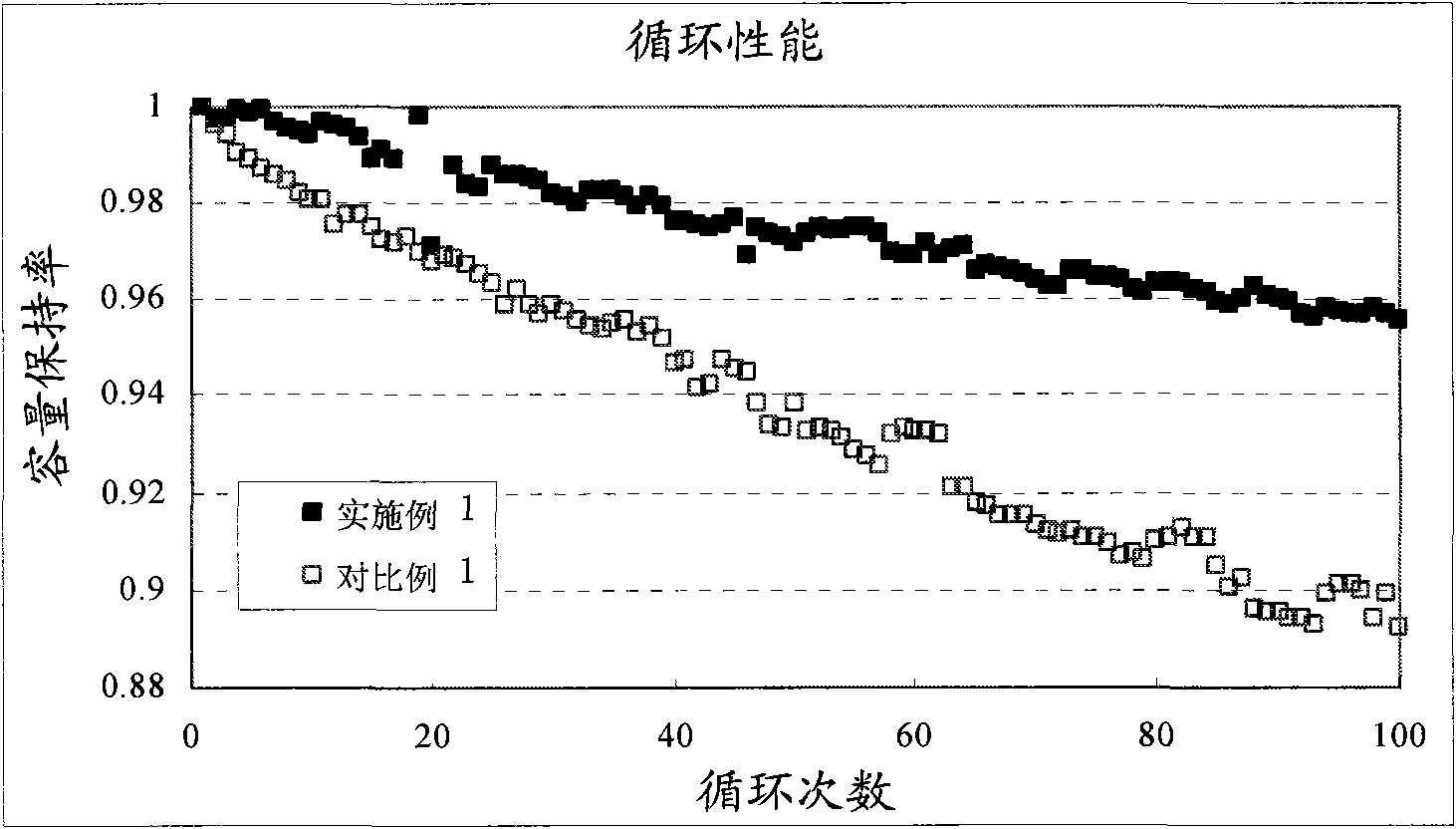

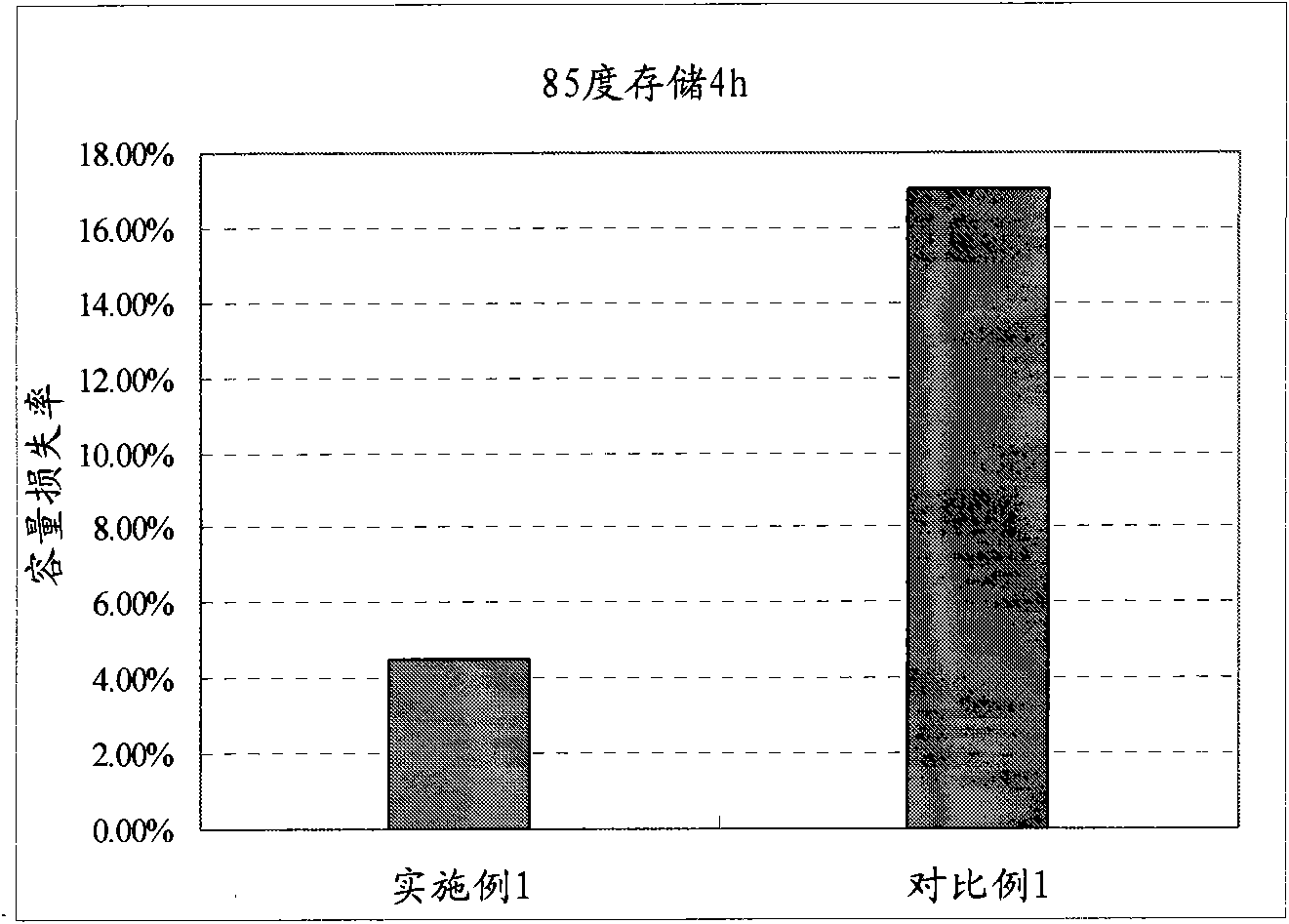

A lithium-ion battery, cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of insignificant improvement in thermal stability and capacity, reduction in material specific capacity, and reduction in initial discharge capacity, etc. Good performance and thermal stability, easy industrial production, and the effect of inhibiting the expansion of the lattice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Lithium carbonate and cobalt oxyhydroxide with a Li:Co molar ratio of 1.04:1 were mixed for 6 hours, sintered at 700°C for 14 hours, cooled to room temperature, crushed and sieved to obtain the precursor.

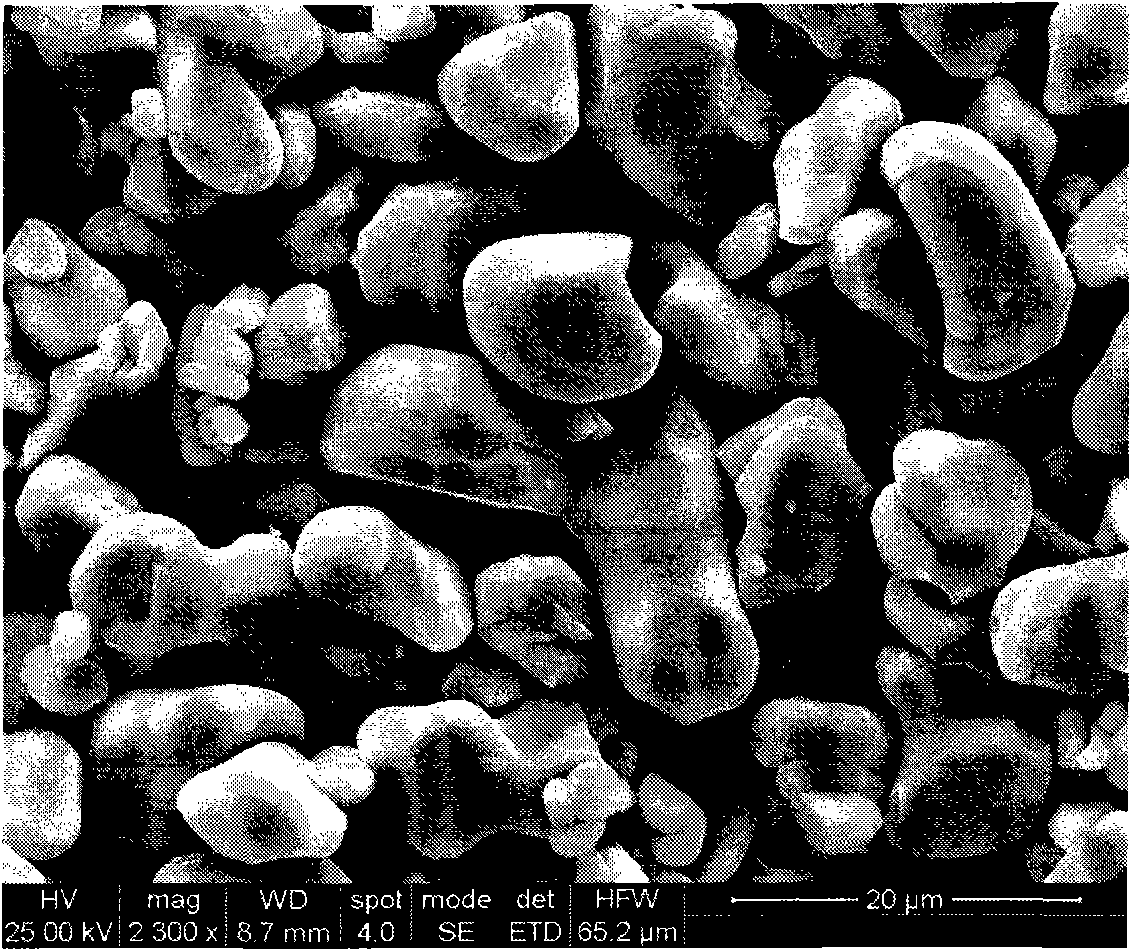

[0030] The precursor, MnO with a molar ratio of 1:0.01:0.005 2 、Al 2 o 3 Mix for 4 hours, sinter at 900°C for 6 hours, cool to room temperature, crush and sieve to obtain the modified lithium cobaltate material, such as figure 1 As shown, the particle size of the primary particle is about 12-25 μm, and the electrical properties of the product are shown in Table 1.

Embodiment 2

[0032] Lithium hydroxide, cobalt oxalate, and manganese dioxide with a molar ratio of Li:Co:Mn of 0.95:1:0.02 were mixed for 5 hours, sintered at 1200°C for 14 hours, cooled to room temperature, crushed and sieved to obtain the precursor.

[0033] The precursor, ZrO with a molar ratio of 1:0.001:0.05 2 、K 2 C 2 o 4 ·H 2 O mixed for 4 hours, sintered at 300°C for 6 hours, cooled to room temperature, crushed and sieved to obtain the modified lithium cobaltate material.

Embodiment 3

[0035] Lithium carbonate, cobalt tetroxide, and boron pentoxide with a molar ratio of Li:Co:B of 1.08:1:0.05 were mixed for 8 hours, sintered at 1000°C for 14 hours, cooled to room temperature, crushed and sieved to obtain the precursor.

[0036] The precursor, Y with a molar ratio of 1:0.005:0.01 2 o 3 , Mg(OH) 2 Mix for 4 hours, sinter at 900°C for 6 hours, cool to room temperature, crush and sieve to obtain the modified lithium cobalt oxide material. The particle size of the primary particles is about 12-18um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com