High-temperature and High-Salt resisting gel water packing-off method

A high-temperature-resistant, gel-based technology, which is applied in earthwork drilling, wellbore/well components, sealing/isolation, etc., can solve problems such as oil plugging but not water blocking, low strength, and lack of selective plugging ability. To achieve the effect of improving the success rate and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Indoor core plugging test

[0025] At 125°C, the cemented quartz sand unfractured cylindrical core and the cemented quartz sand fractured square core were plugged with the main agent of modified tannin extract plugging agent. The results are shown in Table 1 and Figure 4 .

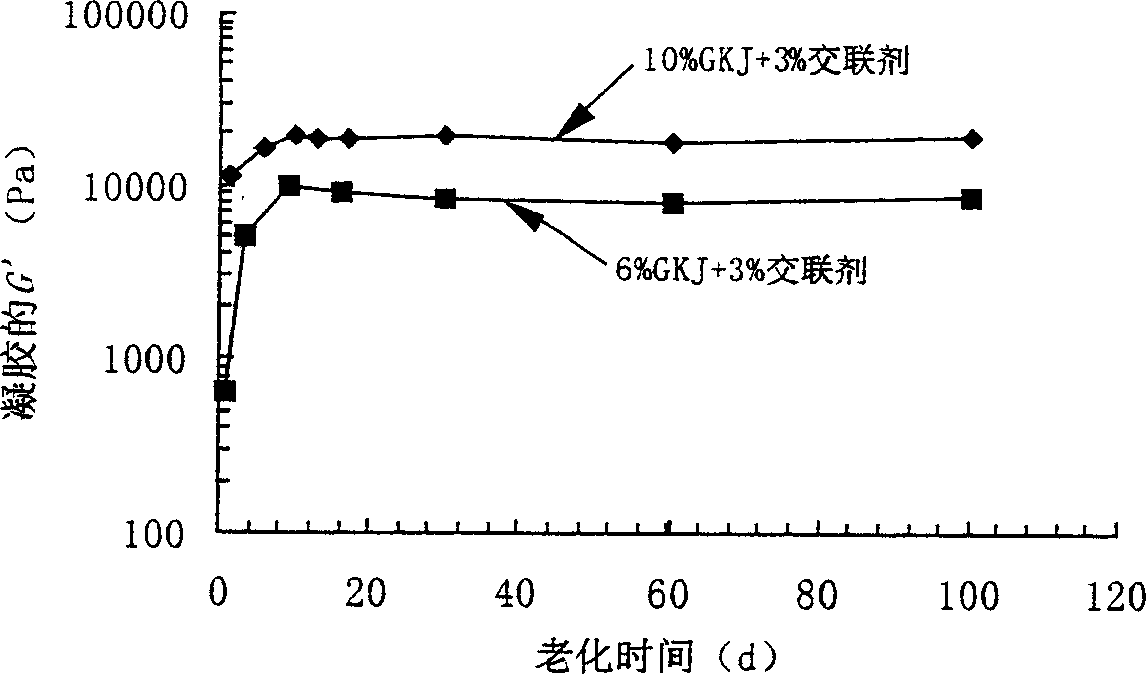

[0026] Water phase permeability of unfractured core (K w ) is 1870.95×10 -3 μm 2 , The plugging agent formula is: 10% GKJ+3% HMTA+1% NaOH. Sol injection equilibrium pressure is 0.011MPa, resistance coefficient (F r ) is 25. At a constant temperature of 125°C for 5 days, the formation water was used to displace the core at a Darcy velocity of 0.879m / d, the measured breakthrough pressure was 0.44MPa / cm, and the residual resistance coefficient (F rr1 ) was 24000, the core was almost completely blocked, and the permeability dropped to 0.08×10 -3 μm 2 . Continue constant temperature aging, after 28d the residual resistance coefficient (F rr2 ) is 20000, indicating that the thermal s...

Embodiment 2

[0030] Example 2 Field Test of Carboniferous Deep Well Bottom Water Plugging in Shixi Oilfield

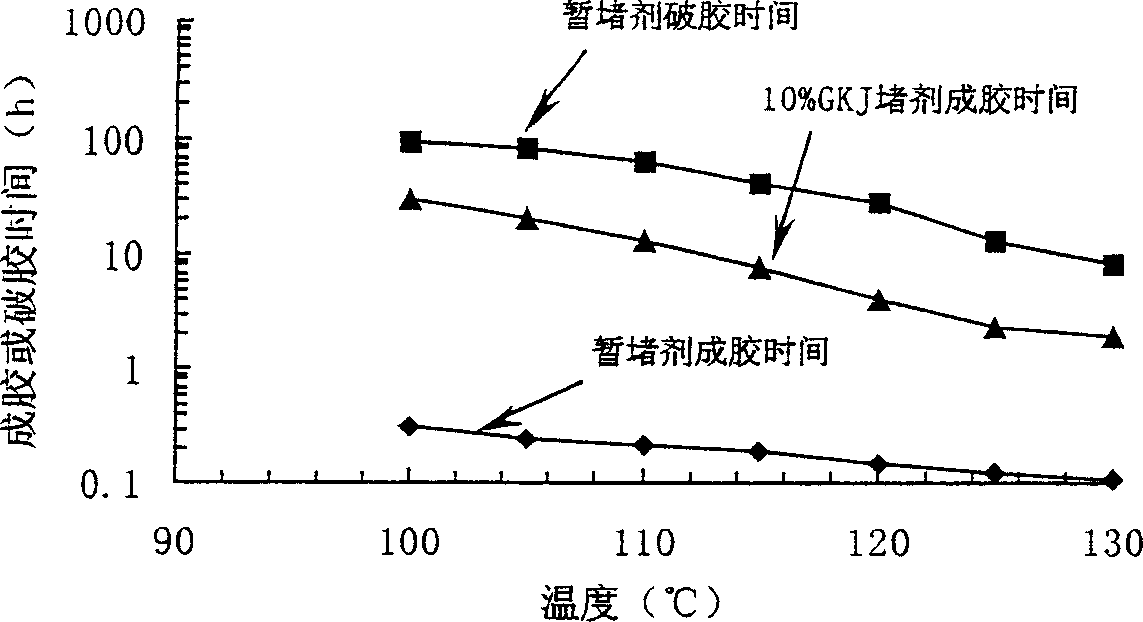

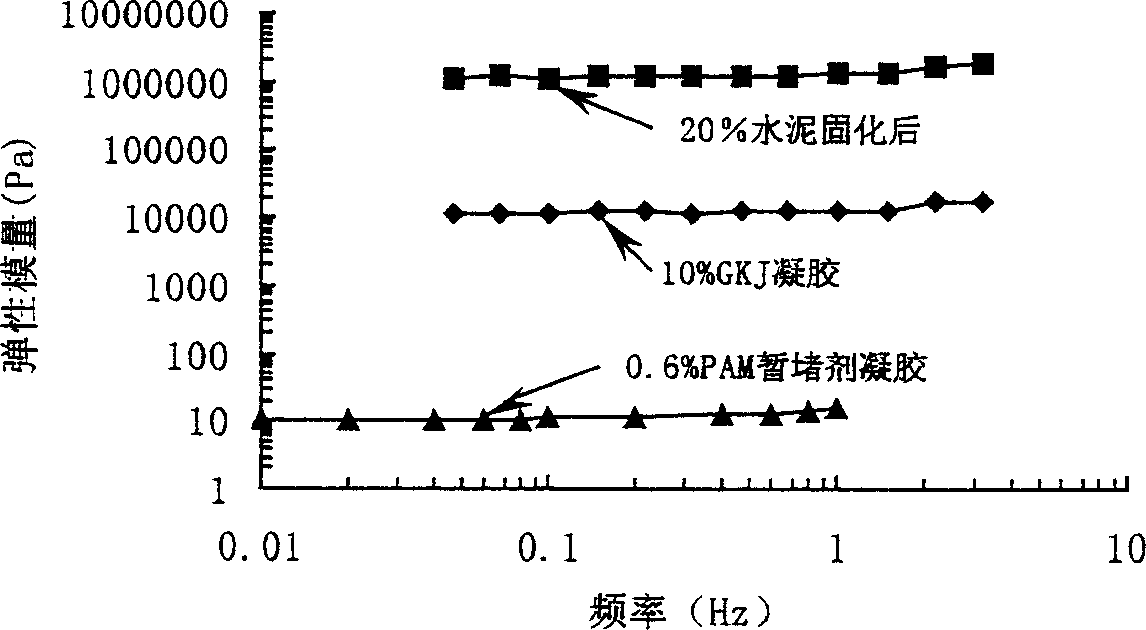

[0031] On October 27, 2001, the on-site construction of Carboniferous deep well bottom water sealing in Shixi Oilfield was carried out. The basic data of Well SH1104 are shown in Table 2. Since the production has been stable for nearly 3 years, the amount of movable oil underground may not be much. Aiming at the serious water flooding of the well and the high outlet pressure that may cause the main agent of the plugging agent to not easily enter the water layer, a special plugging method of temporary plugging agent-modified extract plugging agent main slug-cement sealing slug was adopted. Among them, the formula of the temporary plugging agent is: 0.6% polyacrylamide + 0.1% sodium dichromate + 0.3% anhydrous sodium sulfite; the formula of the modified extract is: 10% GKJ + 3% HMTA + 1% NaOH; the sealing section The plug is: 20% cement + 4% soil + 0.15% sodium borate. It is expect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water phase permeability | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

| Breakthrough pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com