Blood plasma bag air blister squeezer

A technology of extrusion machine and plasma bag, which is applied in the field of plasma bag bubble extrusion machine, can solve the problems of low accuracy, rupture of plasma bag, slow speed, etc., and achieve the effect of improving accuracy and uniform pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

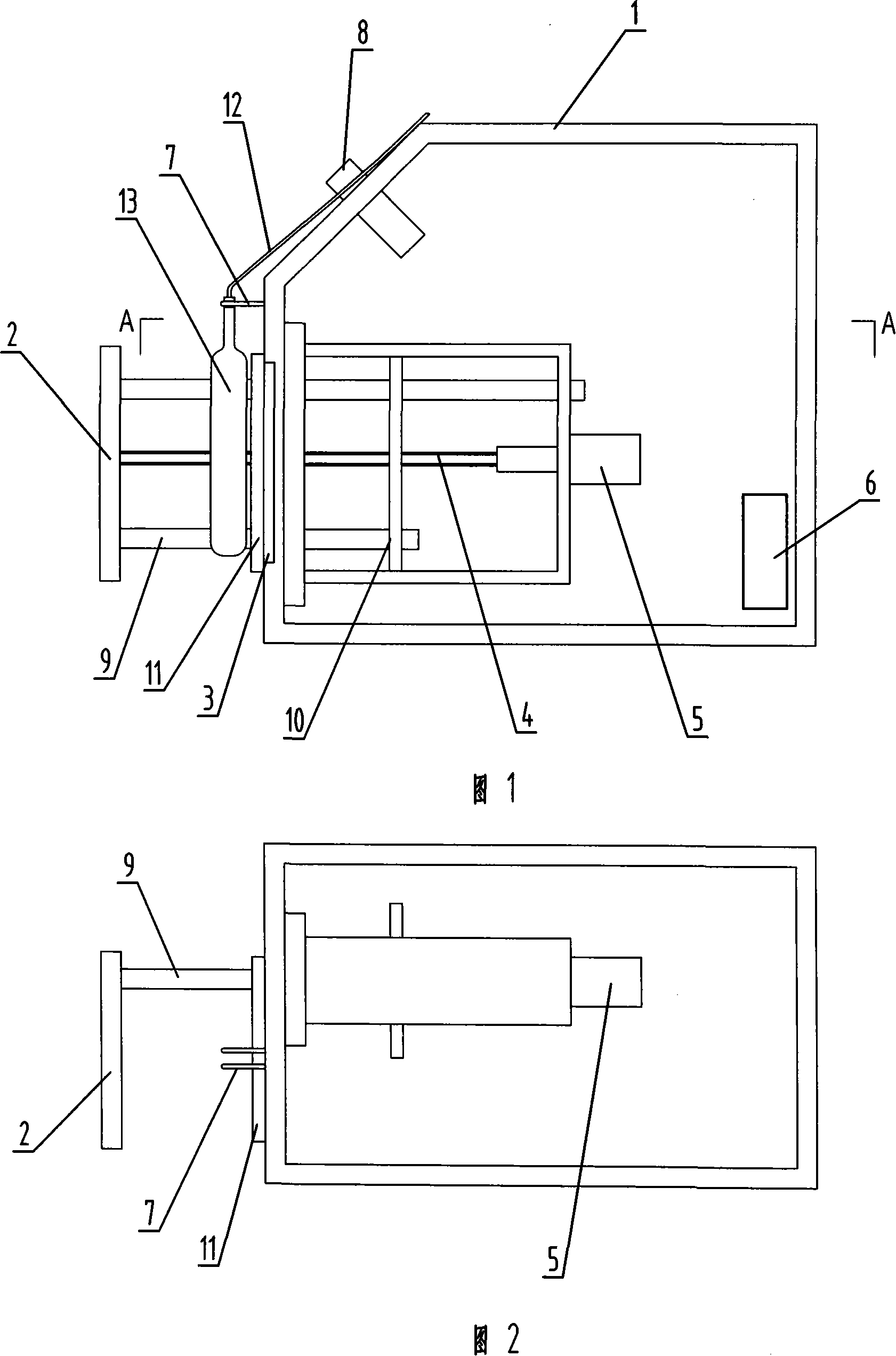

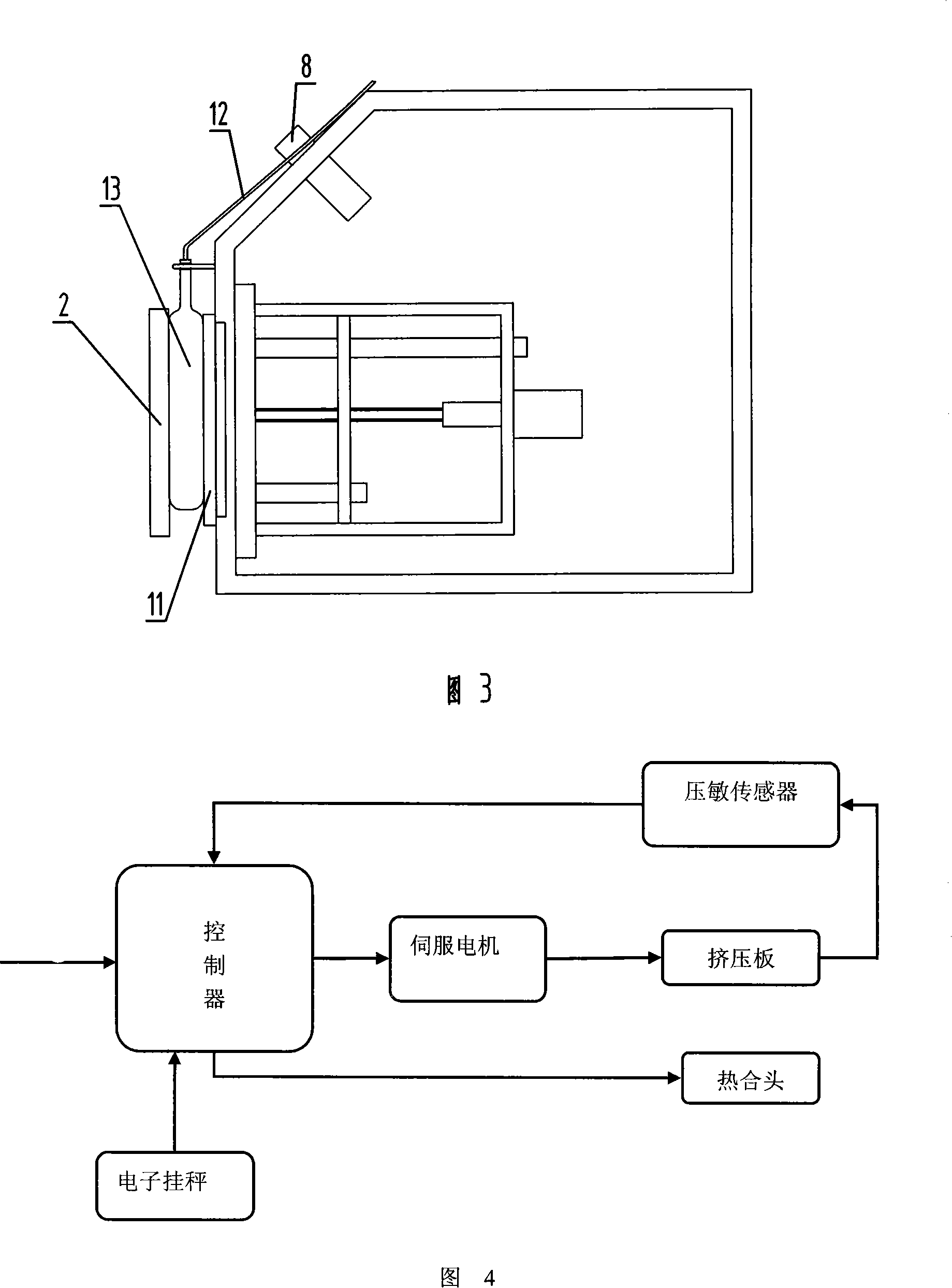

[0024] As shown in Figures 1 and 2, the plasma bag bubble squeezer includes a housing 1, a squeeze plate 2, a screw propulsion mechanism for pushing the squeeze plate 2, a pressure sensor 3, a controller 6, Heat sealing head 8, electronic hanging scale 7. The extruding plate 2 is arranged outside the housing 1 , and the extruding plate 2 is parallel to the outer wall of the housing 1 corresponding to the extruding plate 2 .

[0025] Screw mandrel propulsion mechanism comprises screw mandrel 4, is used to promote the motor 5 of screw mandrel 4, extrusion plate 2 moves guide rod 9, the guide groove 10 of guide rod 9; Motor 5 is a servo motor, and motor 5 is controlled by controller 6. One end of the screw rod 4 is connected with the extruding plate 2 , and the motor 5 is arranged in the casing 1 . One end of the guide rod 9 is connected to the extrusion plate 2 , and the guide groove 10 is arranged in the housing 1 .

[0026] The pressure sensor 3 is arranged on the outer wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com