Eraser carrying micro liquid by itself

A wiper and liquid technology, which is applied in the field of storage and wiping equipment, can solve the problems of complex processing technology, difficulty in opening, and increased manufacturing costs, and achieve the effect of simple process, natural and convenient opening, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

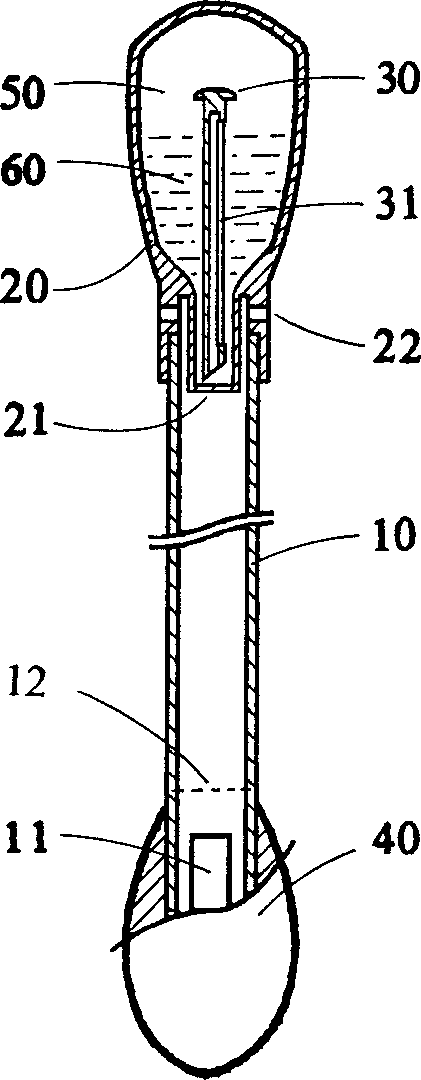

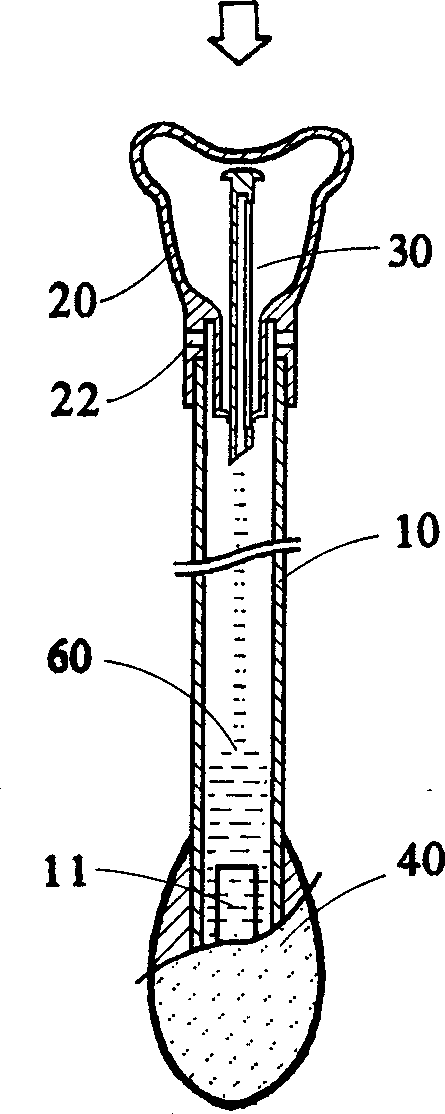

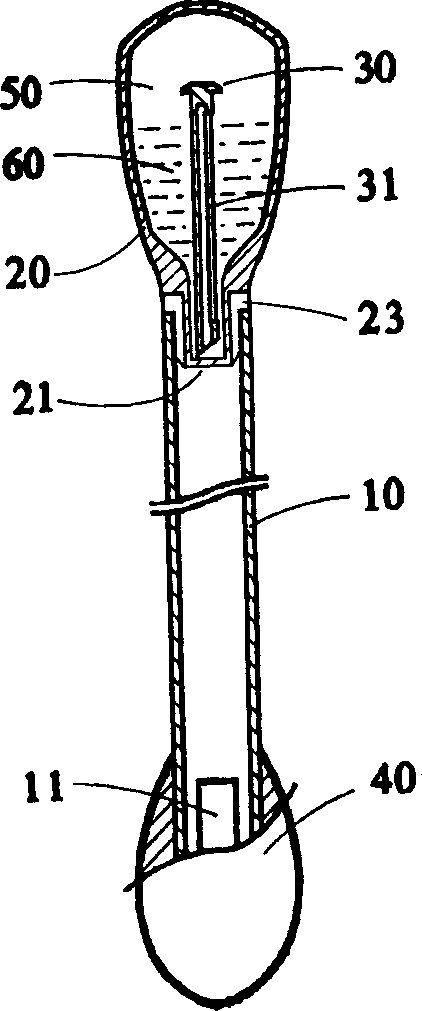

[0051]One of the embodiments: a micro-volume self-carrying liquid wiper, comprising a catheter 10 with two open ends and a capsule container 20 placed at the upper end of the catheter and a soft absorbent body 40 placed at the lower end of the catheter 10, its characteristics In that: the bottom of the capsule container 20 is fused and sealed with an end pipe 21 connected to its inner cavity, so that the capsule container 20 forms a self-closed chamber; an opening element 30 is placed in the self-close chamber; the self-close Gas 50 and working liquid 60 are also placed in the chamber; the lumen at the upper end of the catheter 10 communicates with the outside of the tube.

[0052] The sac-shaped container 20 is a pyramid-like sac-shaped container whose lower part communicates with the end tube 21 of the inner cavity and extends into the lumen of the catheter 10 and is socketed with the catheter 10 through the outer end tube.

[0053] The gas 50 contained in the self-enclosed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com