High-wear-resistant irradiation crosslinked halogen-free flame-retardant automotive wire cable material and preparation process thereof

A technology for automotive wire and cable materials, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., which can solve the problems of high wear resistance, high temperature resistance, oil resistance, rapid extrusion, and non-compliance of automotive wire materials at the same time , to achieve high physical and mechanical properties and improve wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

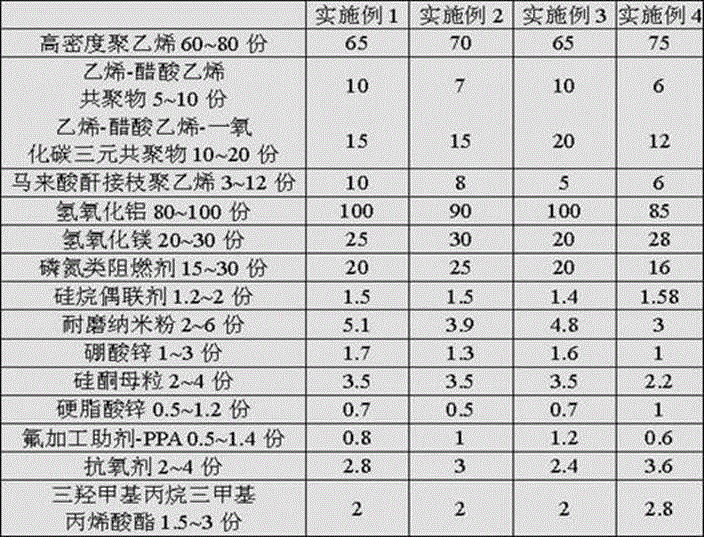

[0042] Embodiments 1~4: high wear-resistant radiation cross-linked halogen-free flame retardant automotive wire and cable material, consisting of the following components by weight:

[0043] Table 1

[0044]

[0045] The above wear-resistant nano powder is ST-NM-001 from Shanghai Paddy Field, with a particle size distribution of about 20 nm;

[0046] The total parts by weight of above-mentioned high-density polyethylene, ethylene-vinyl acetate copolymer, ethylene-vinyl acetate-carbon monoxide terpolymer and compatibilizer are 100 parts;

[0047] The melt index of the above-mentioned high-density polyethylene is 0.08~2g / 10min;

[0048] The vinyl acetate content in the above-mentioned ethylene-vinyl acetate copolymer is 20 to 40%, and the melt index is 0.2 to 5 g / 10min;

[0049] The carbon monoxide content in the above-mentioned ethylene-vinyl acetate-carbon monoxide terpolymer is 8~12%, and the vinyl acetate content in the ethylene vinyl acetate copolymer EVA is 24~30%;

Embodiment 1

[0050] The weights of the silane coupling agents in Examples 1 to 4 are aluminum hydroxide, magnesium hydroxide, phosphorus-nitrogen flame retardants, wear-resistant nano-powders, and the proportions of the total weight of zinc borate are as follows: Example 1 is 1.02%, implementation Example 2 was 0.99%, Example 3 was 0.96%, and Example 4 was 1.19%;

[0051] The melt index of above-mentioned ethylene-vinyl acetate-carbon monoxide terpolymer is 35g / 10min;

[0052] The weights of the fluorine processing aids-PPA of Examples 1 to 4 are the proportions of the weight of the ethylene-vinyl acetate-carbon monoxide terpolymer as follows: Example 1 is 5.33%, Example 2 is 6.7%, and Example 3 is 6% %, Example 4 is 5%.

[0053]The antioxidant in Example 1 is tetrakis[beta-(3,5-di-tert-butyl-4-hydroxyphenyl)propionic acid] pentaerythritol 1010, and the antioxidant in Example 2 is dilauryl thiodipropionate DLTP, The antioxidant in Example 3 is 2-mercaptobenzimidazole zinc salt, and the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com