Multi-functional wet axle of 5-10 T fork-lift truck

A multi-functional, wet technology, applied in the directions of axles, wheels, vehicle parts, etc., can solve the problems of easy slippage between friction plates and spacers, slow braking response time, low safety, etc., to shorten the braking response time, The effect of stable and reliable braking and simplified assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

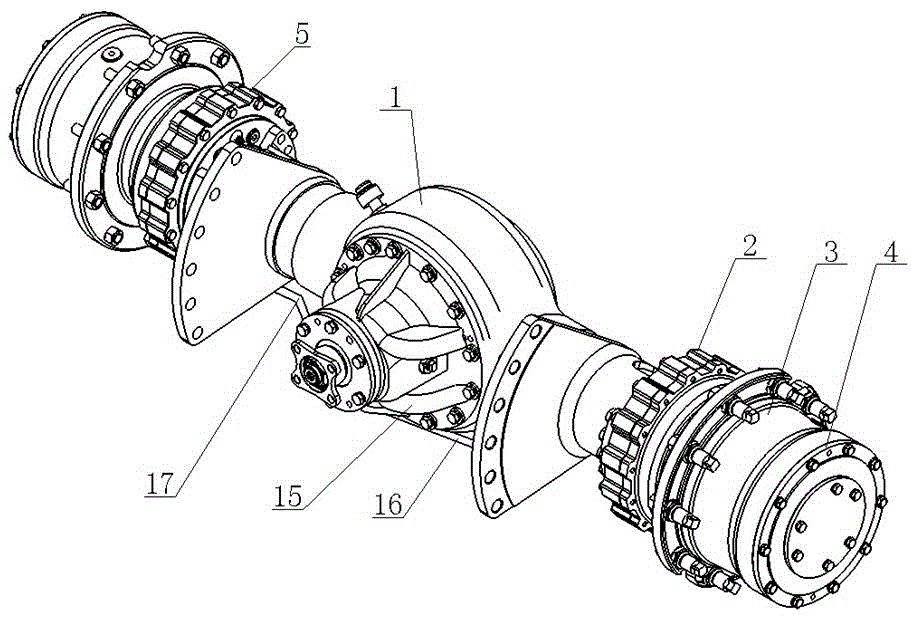

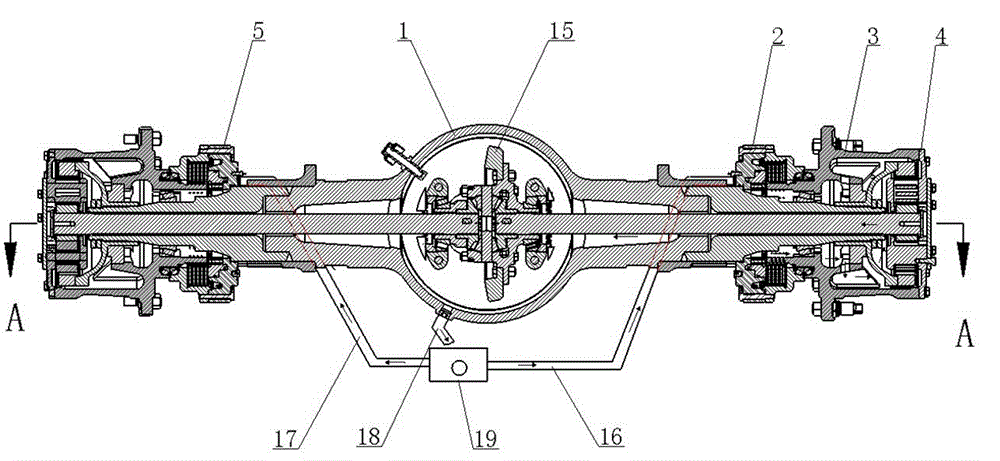

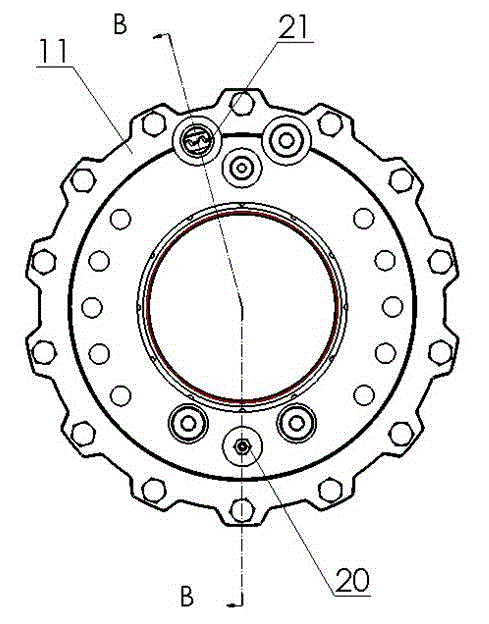

[0026] see figure 1 , figure 2 , Figure 5 , the multi-functional wet axle of a 5-10 ton forklift includes a drive axle housing 1 and a final reducer assembly 15, the left and right sides of the drive axle housing are respectively installed with a right brake 2 and a left brake 5 in sequence, and the outer side of the right brake 2 and the A wheel hub assembly 3 and a wheel-side planetary reduction mechanism 4 are respectively installed on the drive axle housing 1 outside the left brake 5; both the right brake 2 and the left brake 5 are wet brakes. The first lubricating oil passage 21 is opened on the end surface of the inner housing 11 of the brake corresponding to the final reducer assembly 15, and the first lubricating oil passage 21 of the brakes on both sides is respectively connected with one end of the right cooling oil pipe 16 and the left cooling oil pipe. 17, the other end of the right cooling oil pipe 16 is connected to the first port of the tee pipe 19, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com