Powder for preparing polyethylene microporous membrane and its preparation method and application

A polyethylene microporous membrane and polyethylene technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of narrowing the application range of products, demanding polymerization conditions, destroying crystallinity, etc., and achieve molecular weight And the distribution can be adjusted, the effect of improving processing efficiency and high processing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

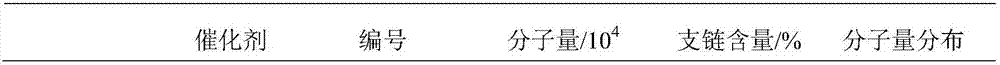

Embodiment 1-6

[0052] Preparation of polyethylene material A:

[0053] Preparation of Mg-Ti-based Ziegler-Natta catalysts: by preparing new eco-magnesium halides, reacting with electron donors, and reacting with titanium compounds (Ti:Mg=0.05) to form Mg-Ti-based Ziegler-Natta catalysts Cat1. For the specific preparation method, refer to the preparation of the catalyst in Example 1 of patent ZL200610116967.1.

[0054] Preparation of Mg-Ti Ziegler-Natta catalysts: magnesium halides react with alcohols to form magnesium compounds, magnesium compounds react with silicon compounds having at least one halogen group to form intermediates, intermediates react with titanium compounds (Ti:Mg =0.1) to form Mg-Ti Ziegler-Natta catalyst Cat2, the specific preparation method refers to the preparation of the catalyst in Example 1 of ZL200710042467.2.

[0055] Polymerization reaction: Heat a 2-liter stainless steel jacketed reactor to 100°C, vacuumize for 3 hours, add 2kg of refined high-purity sodium ch...

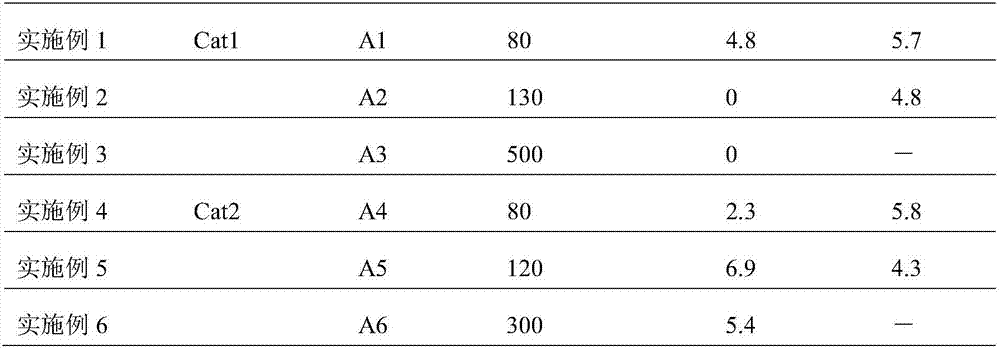

Embodiment 7-12

[0060] Preparation of polyethylene material B:

[0061] The single-site catalyst Cat3 was prepared by supporting pentamethyl-cyclopentadienyl titanium trichloride on triethylaluminum-modified magnesium chloride alcoholate. For the specific preparation method, refer to the first catalyst in Example 1a of patent ZL201210396049.4 Preparation of components.

[0062] The single-site catalyst Cat4 was prepared by loading rac-dimethylsilylbis(1-indenyl)zirconium dichloride on styrene-acrylic acid copolymer. For the specific preparation method, refer to the preparation of the first catalyst component in Example 1a of patent ZL201110355606.3.

[0063] Polymerization reaction: Heat 2 liters of stainless steel jacketed reactor to 100°C, vacuumize for 3 hours, add 1 liter of refined high-purity n-hexane after cooling, add catalyst and cocatalyst methyl aluminoxane, control Al:Ti in 100-150. Raise the temperature to 50°C, feed 0.5Mpa ethylene, and react for 4 hours. During the polymeriz...

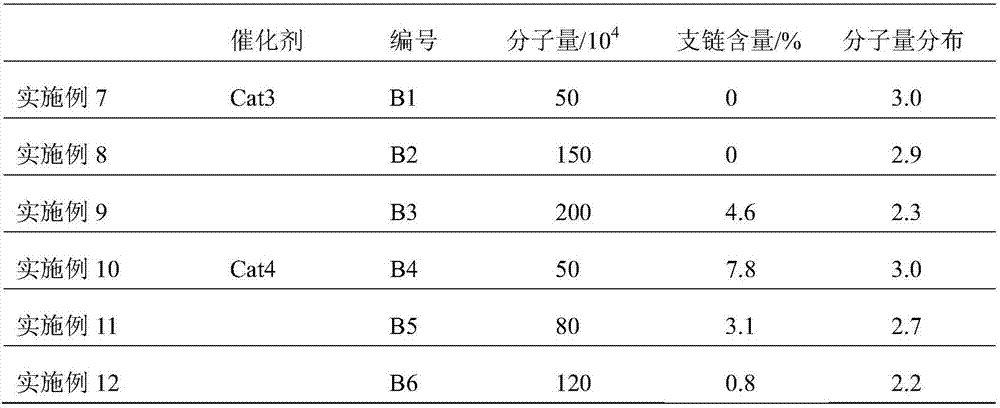

Embodiment 13-23

[0067] A kind of powder material for preparing polyethylene microporous membrane:

[0068] The prepared polyethylene powder A and polyethylene powder B are mixed in a certain proportion to obtain a powder for preparing polyethylene microporous membrane. The results are shown in Table 3.

[0069] Table 3: A kind of powder for preparing polyethylene microporous membrane

[0070]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com