Double-85 (temperature of 85 DEG C and humidity of 85%) yellowing-resistant and low-odor flame-retardant transparent material for optical cable sheaths

A transparent material, low odor technology, applied in the field of double 85 yellow-resistant and low-odor flame retardant transparent materials for optical cable sheath, can solve the problems of moisture resistance, optical cable failure, easy cracking, etc., and achieve excellent low odor performance, The effect of good temperature resistance and yellowing resistance and good flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

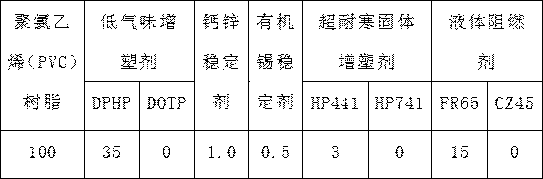

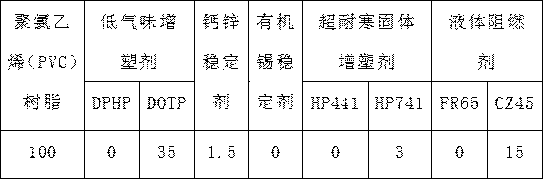

Embodiment 1

[0046] The preparation method of double 85 anti-yellowing low odor type flame retardant transparent material for a kind of optical cable sheath in embodiment one, embodiment two and embodiment three comprises the following steps:

[0047] (1) Weigh the raw materials according to the weight percentage, first add polyvinyl chloride (PVC) resin, low-odor plasticizer and liquid flame retardant into the high-speed mixer and mix at high speed until the temperature rises to 80°C-90°C;

[0048] (2) Add the weighed calcium-zinc composite stabilizer and organotin stabilizer to the high-speed mixer in step (1) for high-speed mixing until the temperature rises to 115°C;

[0049] (3) Add the weighed super cold-resistant solid plasticizer into the high-speed mixer in step (2), mix until the temperature rises to 120°C, put it into a twin-screw extruder to extrude and granulate, and then obtain the double plasticizer for optical cable sheath. 85 Anti-yellowing and low-odor flame-retardant tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com