Yellowing-resistant flame-retardant transparent material for optical cable sheath and preparation method thereof

A transparent material and anti-yellowing technology, which is applied in the field of anti-yellowing flame-retardant transparent materials for optical cable sheaths and its preparation, can solve the problems of easy cracking, optical cable failure, and moisture resistance, and achieve low odor performance and good flame retardancy Characteristics, the effect of good moisture resistance and temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

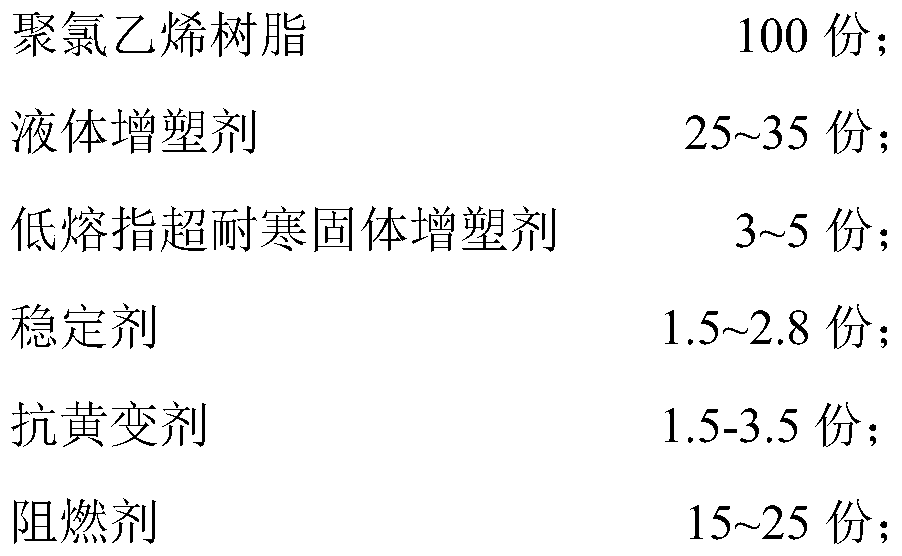

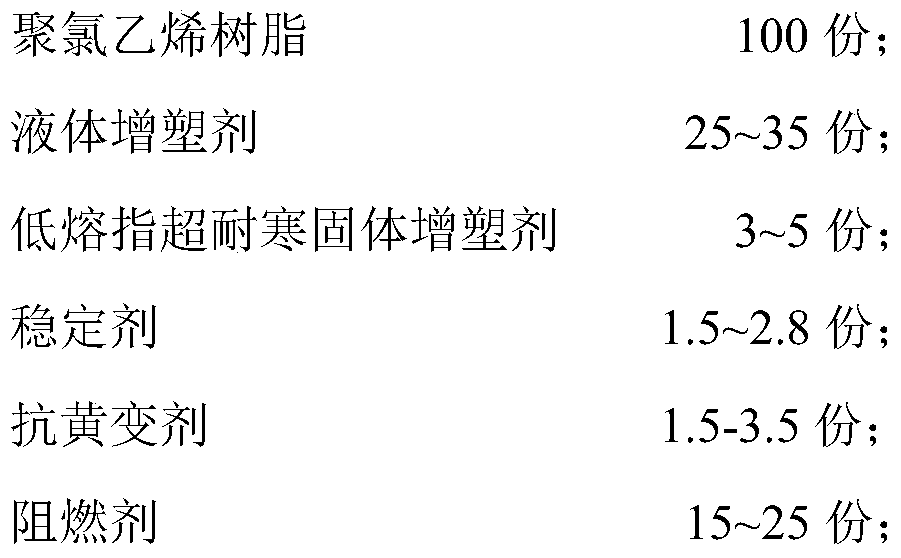

Method used

Image

Examples

preparation example Construction

[0033] Second object of the present invention is to provide a kind of preparation method of anti-yellowing flame retardant transparent material for optical cable sheath, comprising the steps:

[0034] (1) Weigh polyvinyl chloride resin, liquid plasticizer, and flame retardant, add them to a high-speed mixer and mix at high speed until the temperature rises to 80°C to 90°C;

[0035] (2) Add the weighed stabilizer and anti-yellowing agent to the high-speed mixer in step (1) and mix at a high speed until the temperature rises to 115°C;

[0036] (3) Add the weighed low-melting super cold-resistant solid plasticizer into the high-speed mixer in step (2), mix until the temperature rises to 120°C, and put it into a twin-screw extruder to extrude and granulate to obtain the described The cable sheath is made of anti-yellowing and flame-retardant transparent material.

[0037] Wherein, the temperature setting range of the twin-screw extruder is 120°C-165°C, the screw speed is 30-40rpm...

Embodiment 1

[0052]Example 1 added 1.5 parts of calcium-zinc stabilizer and 2.5 parts of anti-yellowing agent, embodiment 2 added 1.0 part of organotin stabilizer and 2.5 parts of anti-yellowing agent, embodiment 3 and embodiment 4 are calcium-zinc stabilizers , organotin stabilizer and anti-yellowing agent three compound system, then as can be seen from the numerical value of double 85, the numerical value of embodiment 1 and 2 is lower than embodiment 3 and 4, it can be seen that the compounding of the three The effect is better than that of non-combined. And the double 85 effect of embodiment 4 is better than embodiment 3, can find out from formula component, the addition of calcium zinc stabilizer, organic tin stabilizer and anti-yellowing agent of embodiment 4 is all higher than embodiment 3, The value of double 85 is better.

[0053] In addition, the yellowing-resistant transparent material used for the sheath of the optical cable of Example 4 and Comparative Example 2 is irradiated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com