Meatball extrusion molding machine for food processing

A food processing and forming machine technology, applied in the direction of processed meat, meat processing equipment, applications, etc., can solve the problems of labor-intensive, unrounded meatball shape, poor forming effect, etc., achieve simple and convenient position adjustment, and avoid loose meatballs , Squeeze convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

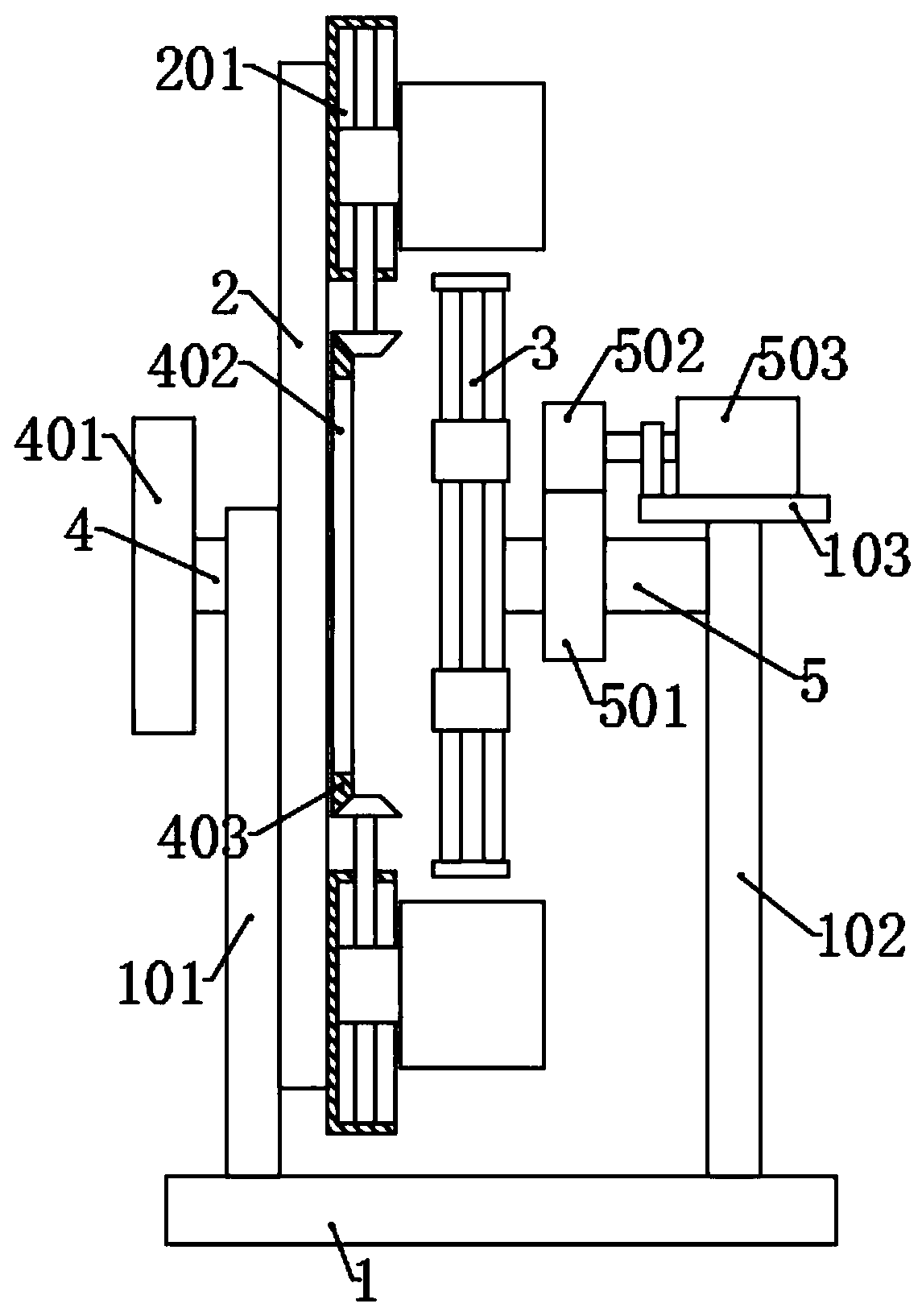

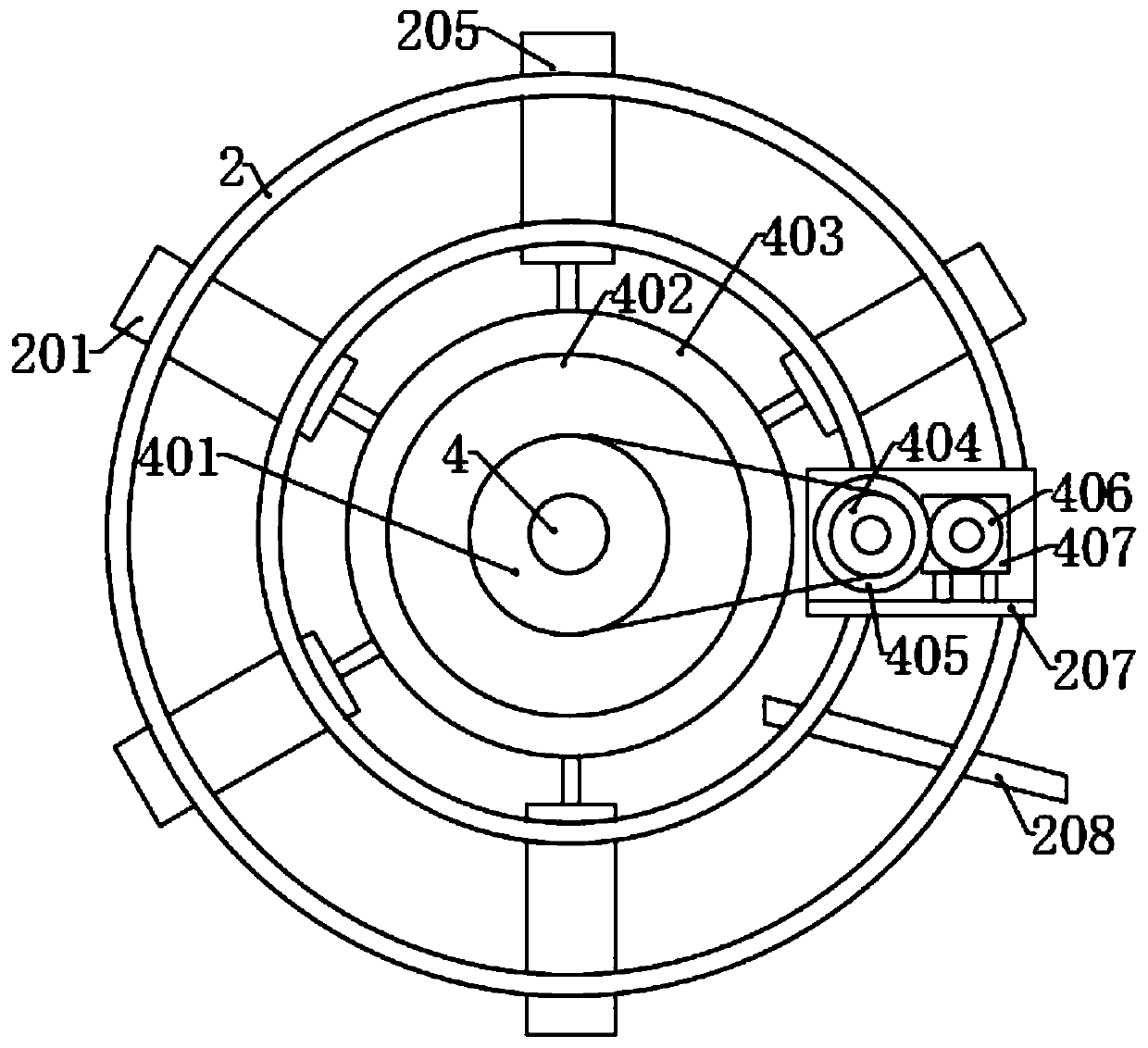

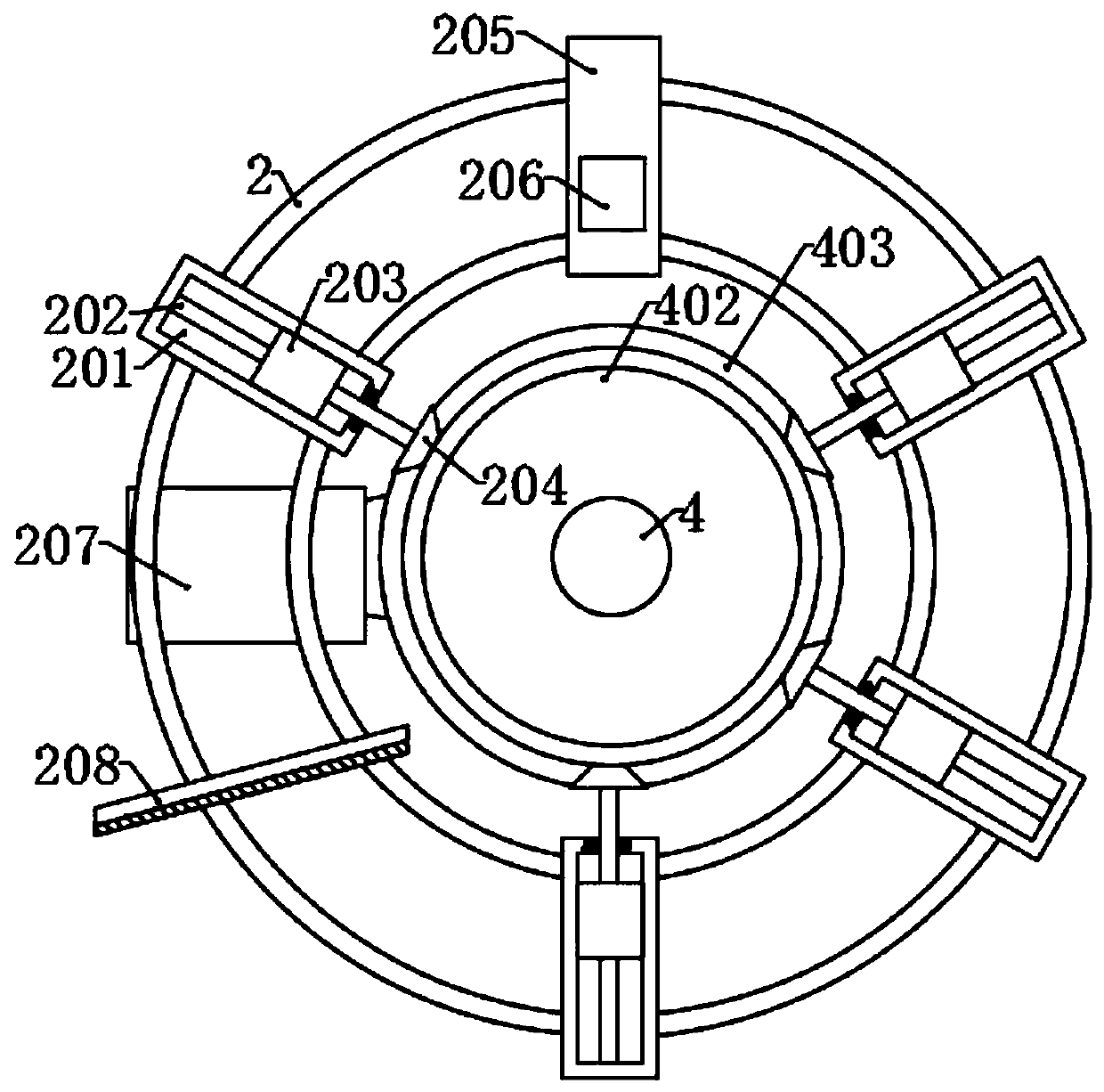

[0042] Please refer to the accompanying drawings, the present invention provides a technical solution: a ball extrusion molding machine for food processing, comprising a base 1, a left bracket 101 and a right bracket 102 are respectively fixed on both sides of the base 1, the left bracket 101 is fixed with a fixed frame 2, and the right bracket 102 is rotatably connected with a turret 3, and the fixed frame 2 is sequentially and uniformly arranged with a scraping mechanism 9, a cleaning mechanism 8, a powder brushing mechanism 7, and a feeding mechanism along the circumferential direction. 6. The extrusion mechanism 10 and the blanking plate 208, the fixed frame 2 is also provided with a driving mechanism, the first driving mechanism is connected with the scraping mechanism 9, the cleaning mechanism 8, the powder brushing mechanism 7 and the extrusion mechanism 10, The turret 3 is evenly provided with six extruding assemblies along the circumferential direction, and is connecte...

Embodiment 2

[0053] On the basis of the first embodiment, a spring piece 303 is provided between the installation plate 11 and the installation platform, and a vibrator is also provided on the installation platform.

[0054] When blanking, there may be a situation where the balls stick to the bottom of the extrusion cylinder 1101 and cannot be automatically unloaded. Therefore, when the extrusion cylinder 1101 rotates to the blanking plate 208, open the vibrator on the mounting plate 11, The mounting plate 11 and the extruding cylinder 1101 are vibrated, so that the meatballs are separated from the extruding cylinder 1101 and fall to the blanking plate 208, effectively avoiding the problem of the sticking of the meatballs and improving the feeding speed.

Embodiment 3

[0056] On the basis of the second embodiment, it also includes a controller, the controller and the first motor 503, the second motor 407, the third motor 709, the fourth motor 802, the fifth motor 902, the sixth motor and the seventh motor, so that each The motor is set according to the working principle to work at the corresponding time and corresponding speed, so as to realize automatic processing, save time, improve work efficiency and accuracy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com