Test clamp suitable for high-temperature lasting creep deformation of plate-like test sample

A technology for plate-shaped specimens and creep tests, which is applied to measuring devices, instruments, scientific instruments, etc., can solve the problems of test result influence, reduce data reliability, increase test failure, etc., so as to reduce the probability of test failure and improve test performance. Flexibility, avoiding the effect of data inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

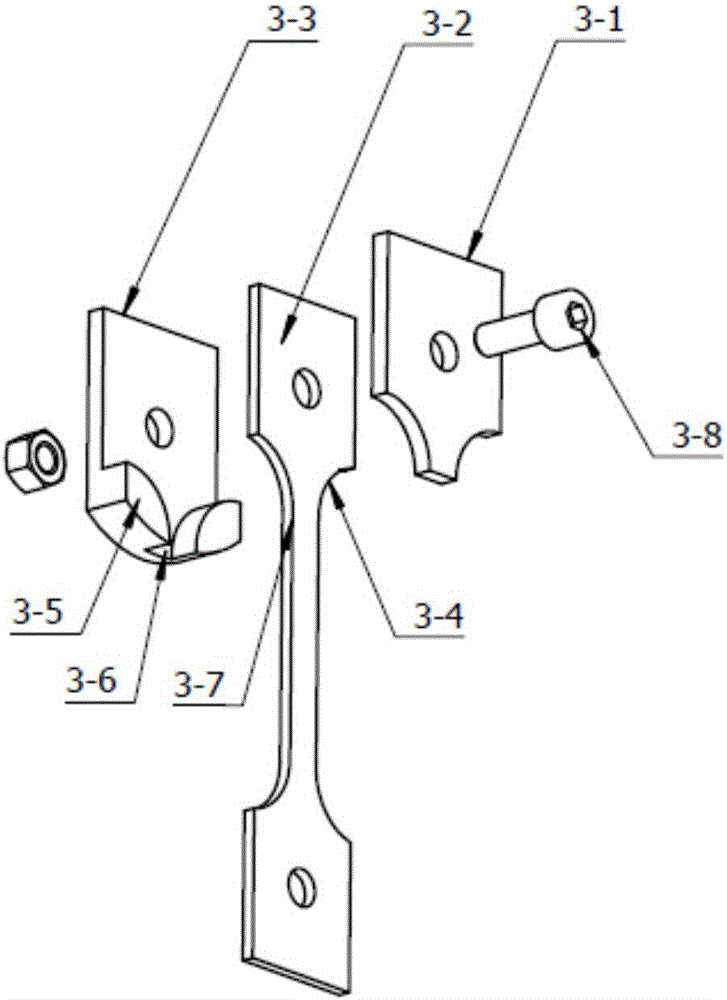

[0032]In the example, the thickness of the sample is 1.5mm, and the block assembly of the corresponding specification is selected to carry out the test. Before the test, the clamping of the plate sample and the pad assembly is completed on the operating platform. When clamping the sample, the nuts do not need to be tightened too tightly, as long as the components 3-1, 3-3 and the clamping end 3-2 of the sample are in good contact. Then, place the pad assembly and the plate-shaped sample as a whole into the arc-shaped groove at the bottom of the inner cavity of the fixture to complete the connection between the fixture and the plate-shaped sample.

[0033] For materials with limited size, the size of the clamping end of the plate-shaped sample can be appropriately reduced. If necessary, the clamping end of the plate-shaped sample can not be processed with round holes, which will not affect the clamping of the sample and the durable creep test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com