Liquefied natural gas tanker container nesting method

A technology of liquefied natural gas and tank trucks, which is applied to fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc., and can solve problems such as long construction time, difficult pumping, and damage to the insulation layer of the inner tank. Achieve the effects of shortened operation time, high safety and precise positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention is provided by the following embodiments, which will be described below in conjunction with the accompanying drawings.

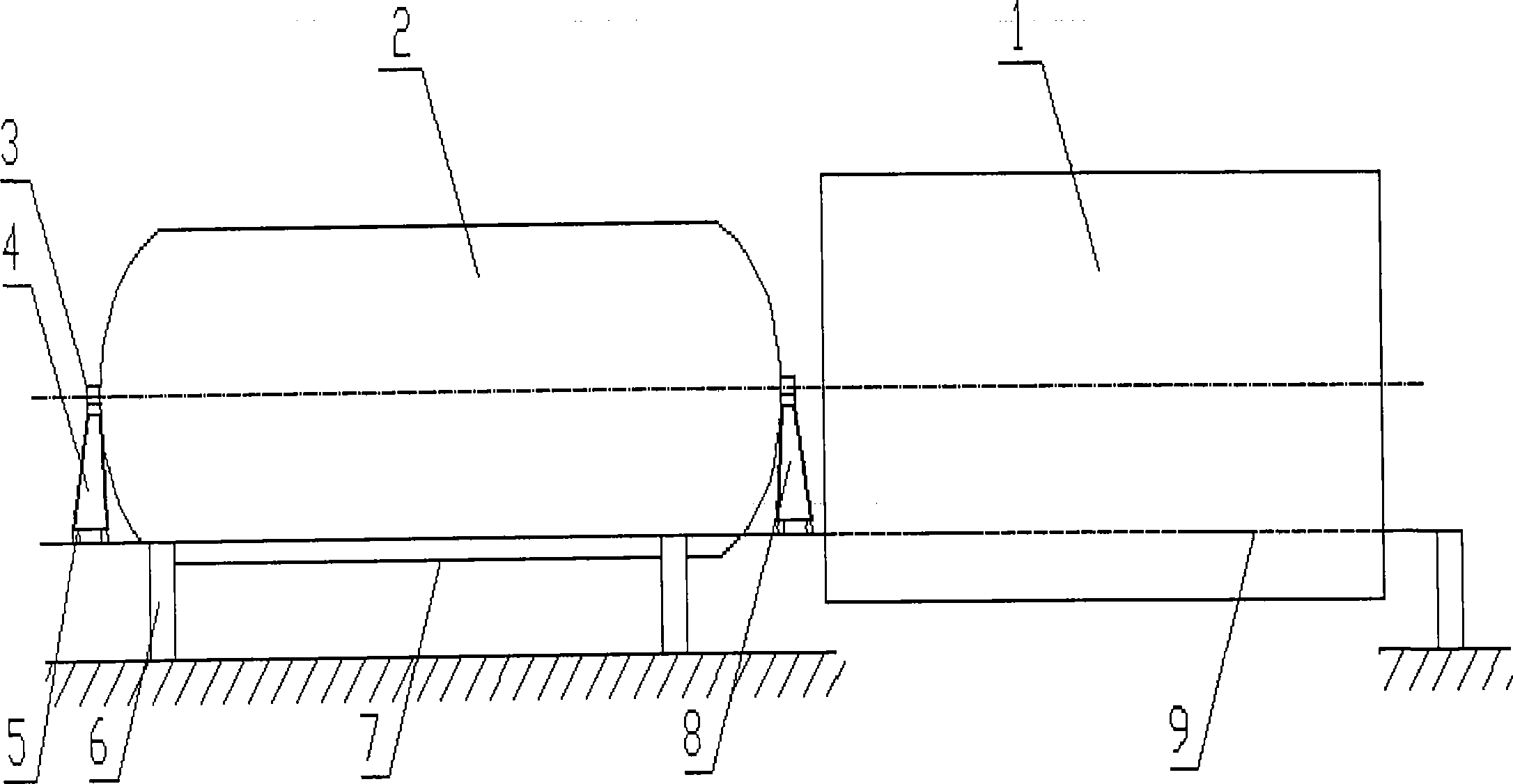

[0011] As shown in Figure 1, the present invention consists of an outer tank body 1, an inner tank body 2, an assembly process tube 3, a rear end support frame 4, a concave wheel 5, a guide rail support 6, an outer guide rail 7, a front end support frame 8, and an inner guide rail 9, the inner side of the outer tank body forms an angle of 30° with the center vertical line, and two angle steel guide rails 9 are longitudinally welded parallel to the central axis of the cylinder body. The length of an inner tank body 2, the outer guide rail 7 has a reliable support 6. The inner tank body 2 is set up at the assembly process tube place 3 at the two ends of the inner tank body 2 through the front end support frame 8 and the rear end support frame 4. The concave wheel 5 that the internal guide rail 9 cooperates, the front end support f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com