Thin-wall tube body fastening device

A fastening device, a technology of thin-walled cylinder, applied in the direction of expanding the mandrel, etc., can solve the problems of low machining accuracy, large deformation of the cylinder, low coaxiality of the two ports of the cylinder, etc., and achieves high machining accuracy and fixed Simple, highly coaxial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

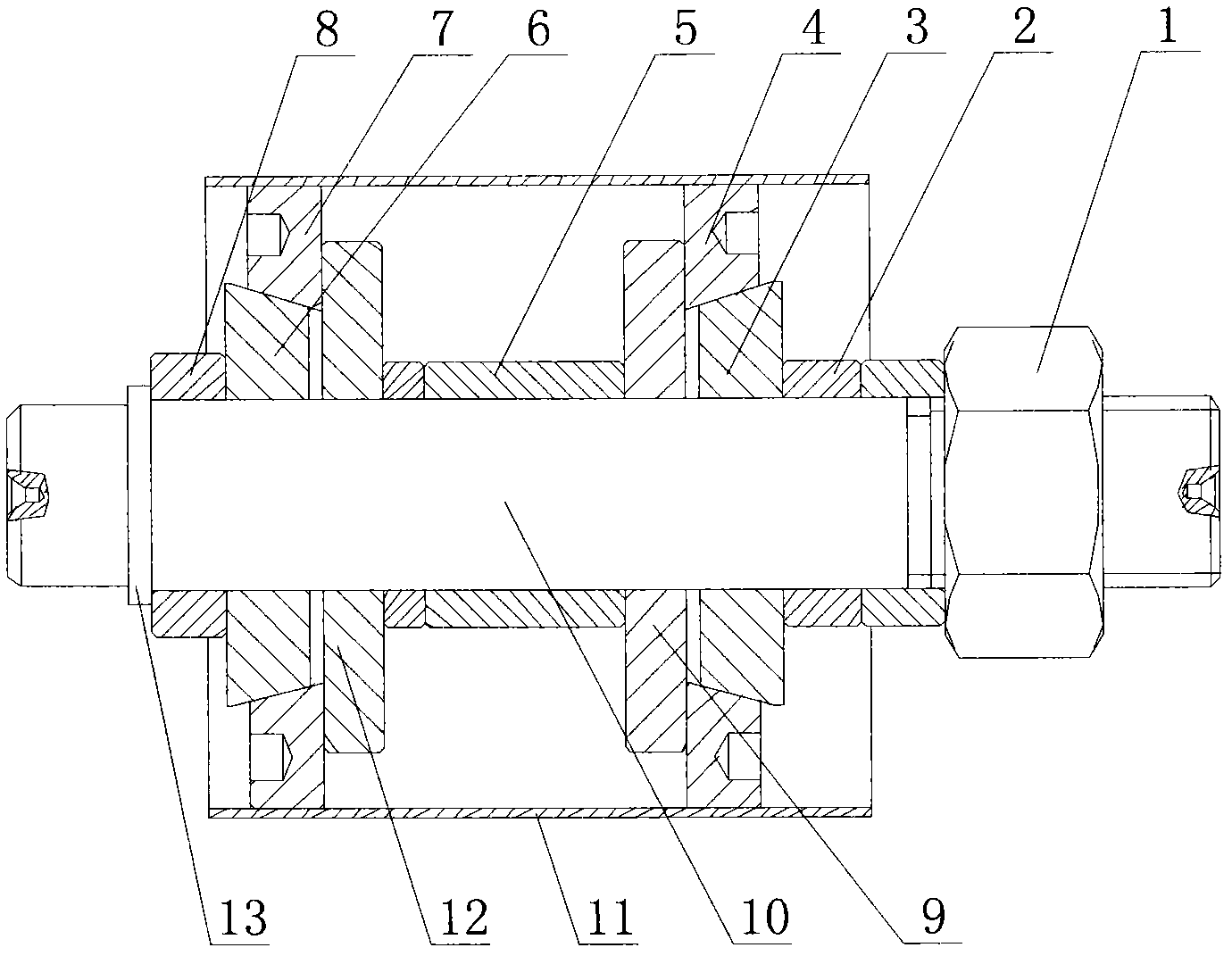

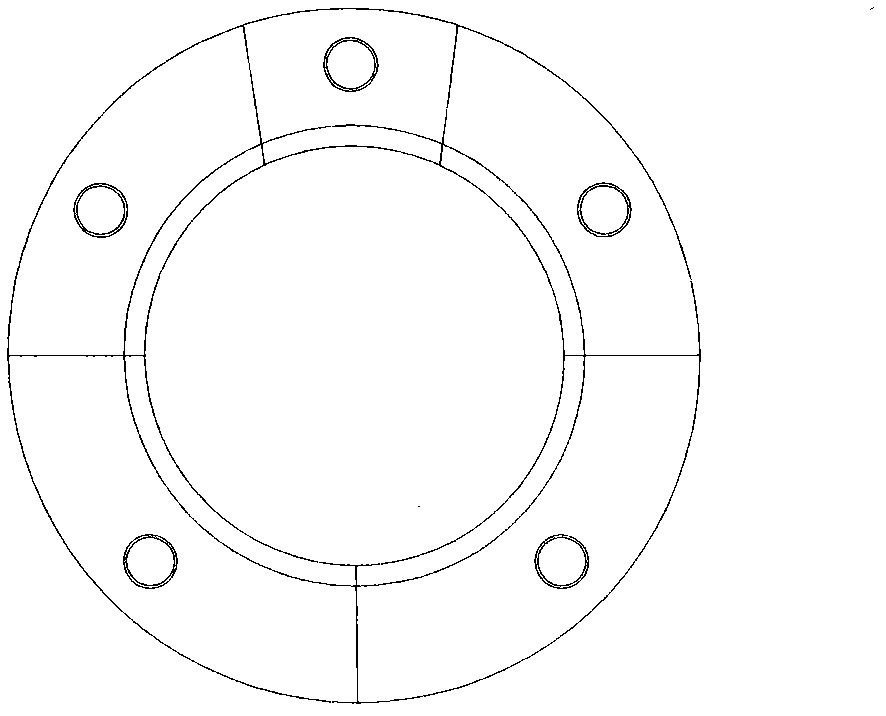

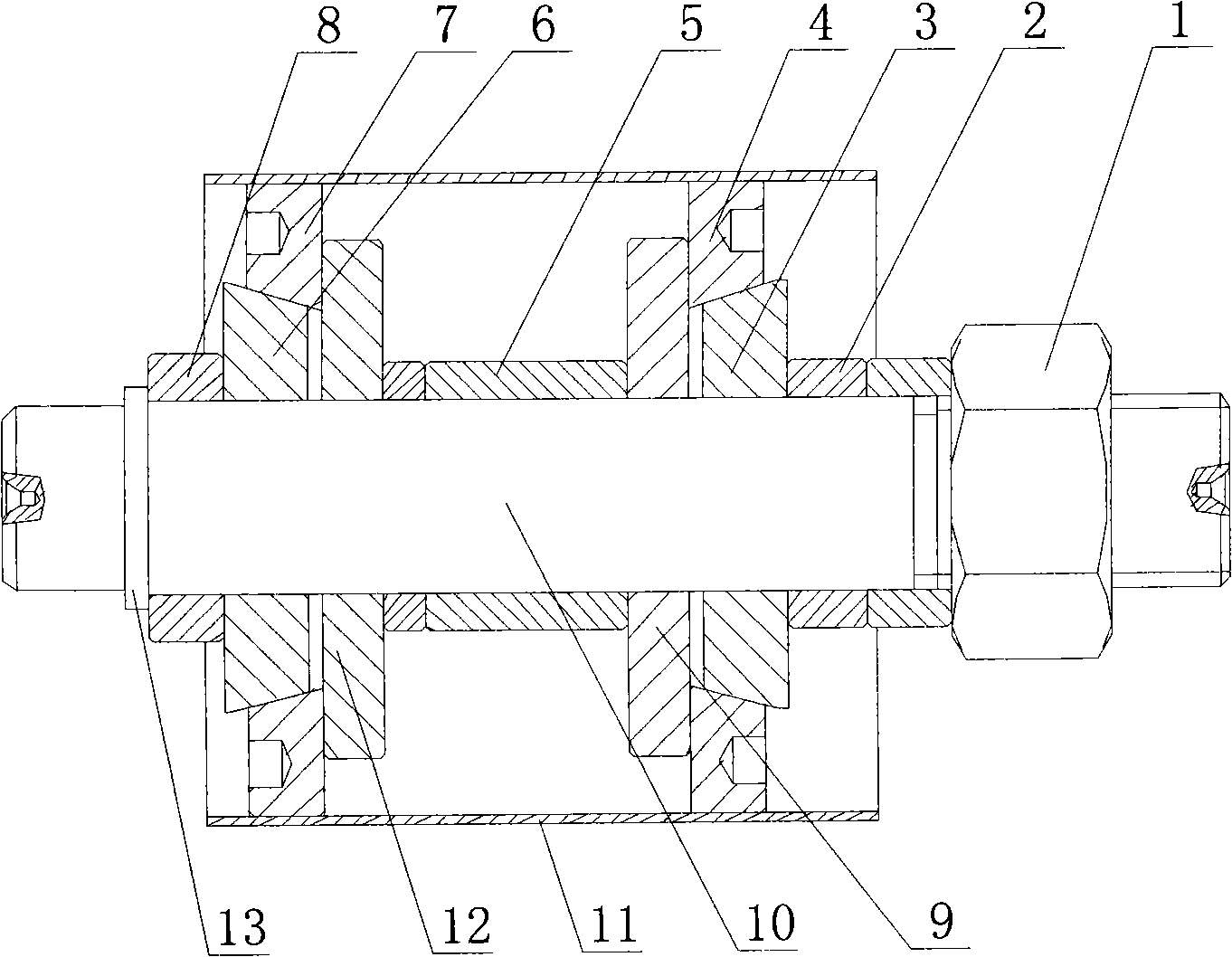

[0007] Such as figure 1 , figure 2 The shown thin-walled cylinder fastening device is provided with a mandrel 10, a spacer 5 is provided in the center of the mandrel 10, and a left baffle 12, a left taper sleeve 6, Left pressing block 8, retaining ring 13, right baffle plate 9, right taper sleeve 3, right pressing block 2, spacer sleeve 10, left baffle plate 12, left taper sleeve 6 are arranged in sequence on the mandrel 10 on the right side of spacer 5 , the left briquetting block 8, the right baffle plate 6, the right taper sleeve 3, and the right briquetting block 2 can all slide on the mandrel, the left baffle plate 12 and the left taper sleeve 6, the right baffle plate 9 and the right taper sleeve 3 respectively There is an axial gap, the retaining ring 13 is fixedly arranged on the mandrel 10, the mandrel 10 on the right side of the right pressure block 2 is provided with a fastening nut 1, and the outer peripheral tapered surfaces of the left taper sleeve 6 and the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com