Novel ultra-high-power cementing equipment integrated with remote control

A remote control, ultra-high power technology, applied in the direction of mechanical equipment, wellbore/well components, liquid fuel engines, etc., can solve the problems of high single operation cost, complicated pipeline connection, and many operators, and achieve single operation cost The effect of low cost, simple pipeline connection and low maintenance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

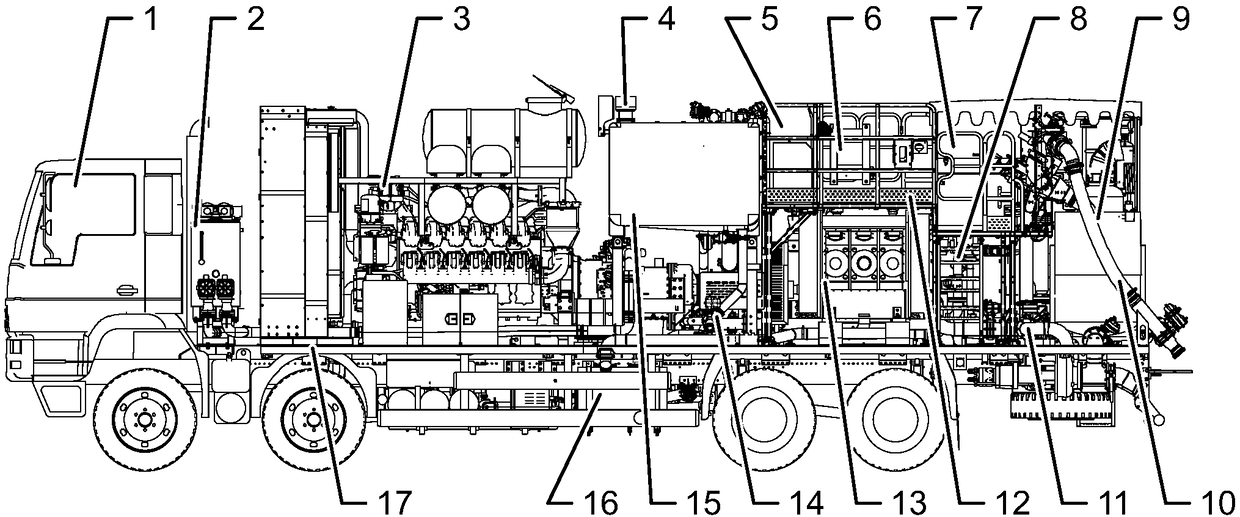

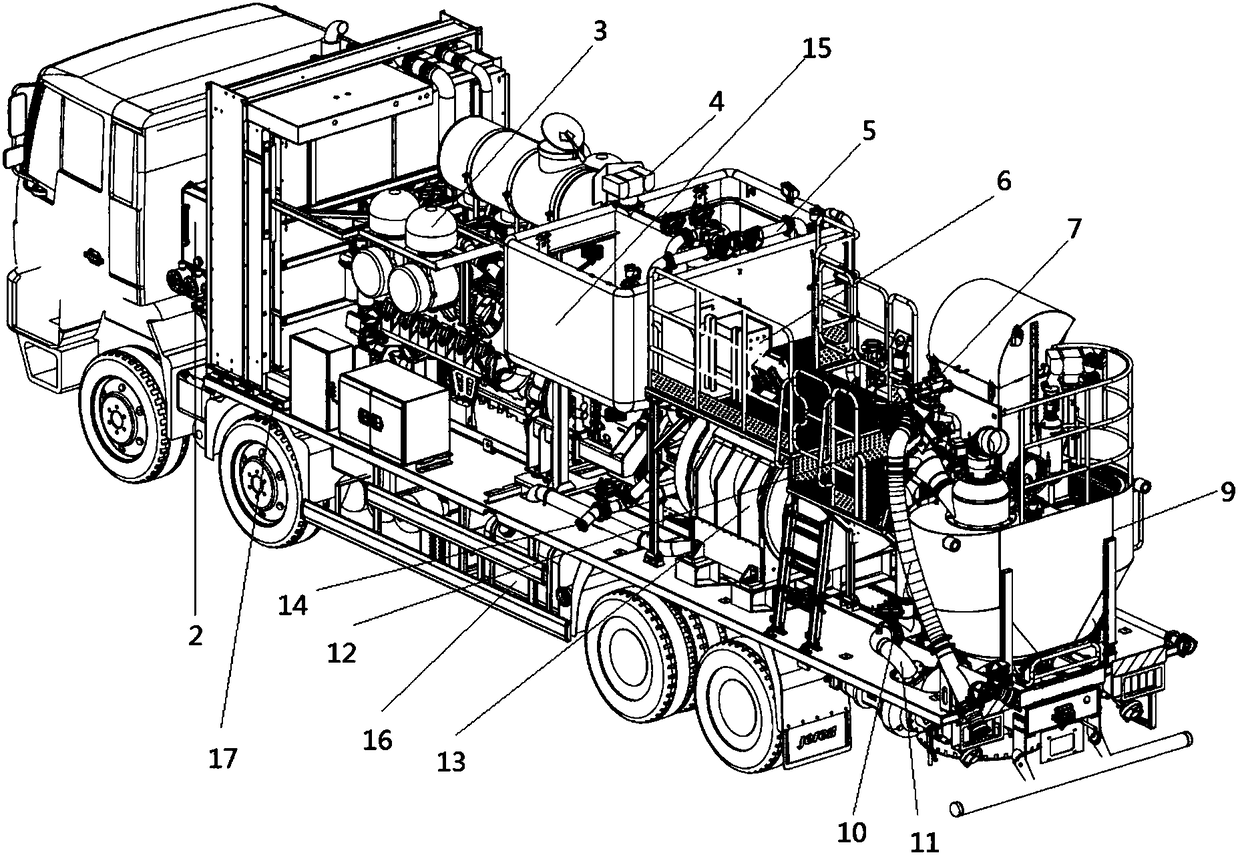

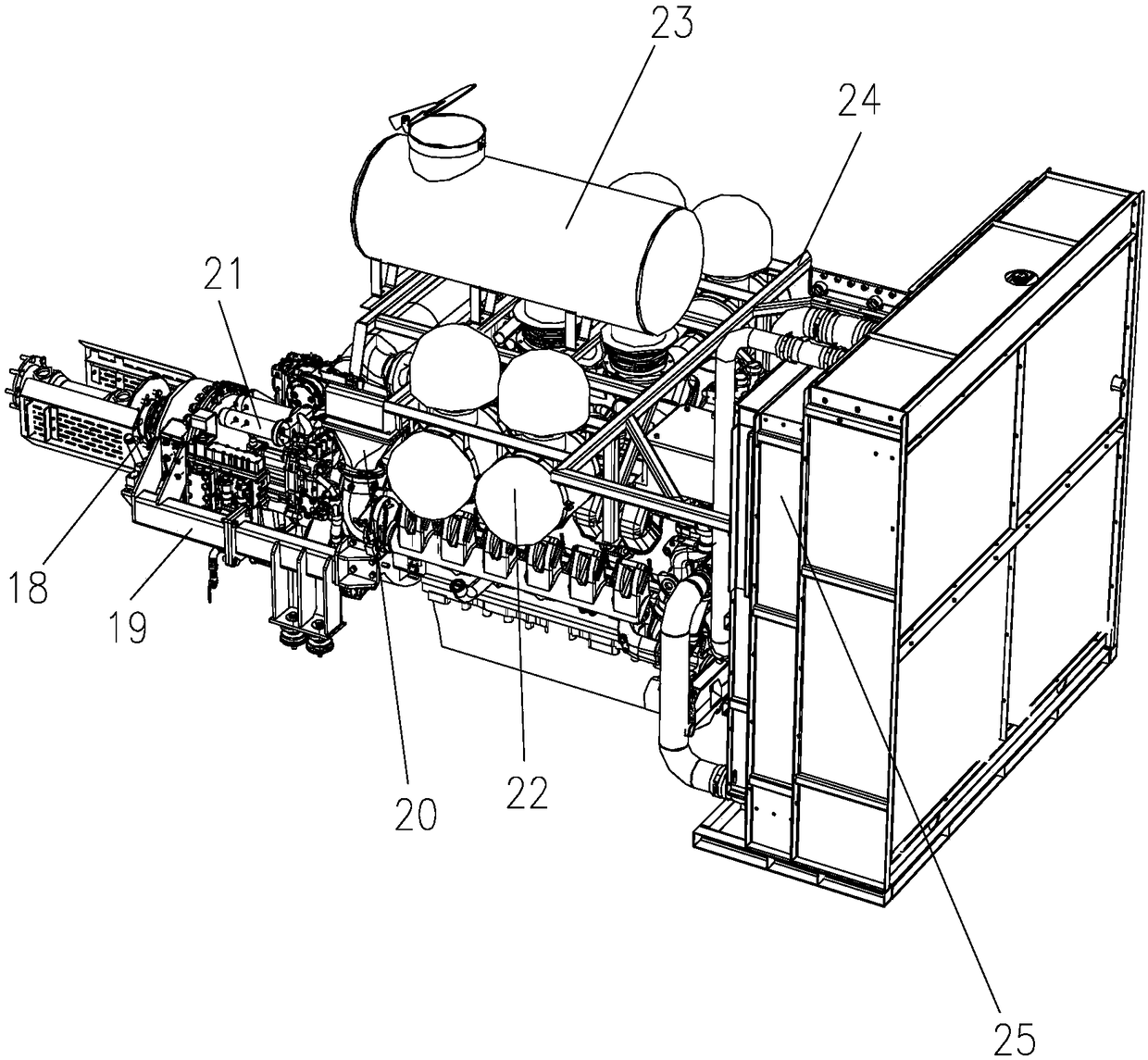

[0052] Such as Figure 1-3 Shown: a new type of ultra-high-power cementing equipment with remote control, including a loading system 1 and a sub-beam 17, the sub-beam 17 is connected to the loading system 1, and the sub-beam 17 is connected to the hydraulic system 2 and the power transmission system in sequence from front to back 3. Measuring tank 15, low-pressure manifold system, operating platform 12 and electrical system 4, gas system 5, control system 7, plunger pump 13, high-pressure manifold 8 and mixing system 9 arranged on the upper end of operating platform 12; column The plunger pump 13 is located at the lower part of the gas circuit system 5. The rated input power of the plunger pump 13 is ≥ 1200hp. The plunger pump 13 is connected to the high-pressure discharge system. The switch, the downstream end of the plug valve is provided with a filter pressure reducing valve, which is used to adjust the working pressure of the whole system and filter the gas entering the sy...

Embodiment 2

[0066] A new type of ultra-high-power cementing equipment with remote control, including a loading system 1 and a sub-beam 17, the sub-beam 17 is connected to the loading system 1, and the sub-beam 17 is connected to the hydraulic system 2, the power transmission system 3, and the metering system from front to back. Tank 15, low-pressure manifold system, operating platform 12 and electrical system 4, gas circuit system 5, control system 7, plunger pump 13, high-pressure manifold 8 and mixing system 9 arranged on the upper end of the operating platform 12; plunger pump 13 Located at the lower part of the gas circuit system 5, the rated input power of the plunger pump 13 is ≥1200hp, and the plunger pump 13 is connected to the high-pressure discharge system. The gas circuit system 5 is provided with a plug valve, which is the main switch of the gas circuit system. The downstream end of the valve is provided with a filter pressure reducing valve, which is used to adjust the working...

Embodiment 3

[0080] A new type of ultra-high-power cementing equipment with remote control, including a loading system 1 and a sub-beam 17, the sub-beam 17 is connected to the loading system 1, and the sub-beam 17 is connected to the hydraulic system 2, the power transmission system 3, and the metering system from front to back. Tank 15, low-pressure manifold system, operating platform 12 and electrical system 4, gas circuit system 5, control system 7, plunger pump 13, high-pressure manifold 8 and mixing system 9 arranged on the upper end of the operating platform 12; plunger pump 13 Located at the lower part of the gas circuit system 5, the rated input power of the plunger pump 13 is ≥1200hp, and the plunger pump 13 is connected to the high-pressure discharge system. The gas circuit system 5 is provided with a plug valve, which is the main switch of the gas circuit system. The downstream end of the valve is provided with a filter pressure reducing valve, which is used to adjust the working...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com