Cold sterilization and fresh-keeping technology and method with high-voltage electric field low-temperature plasma for low-salt pickled vegetables

A low-temperature plasma and high-voltage electric field technology, applied in the direction of food electric treatment, preservation of fruits/vegetables by radiation/electric treatment, climate change adaptation, etc., to extend shelf life, improve storage stability, and avoid loss of sensory quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

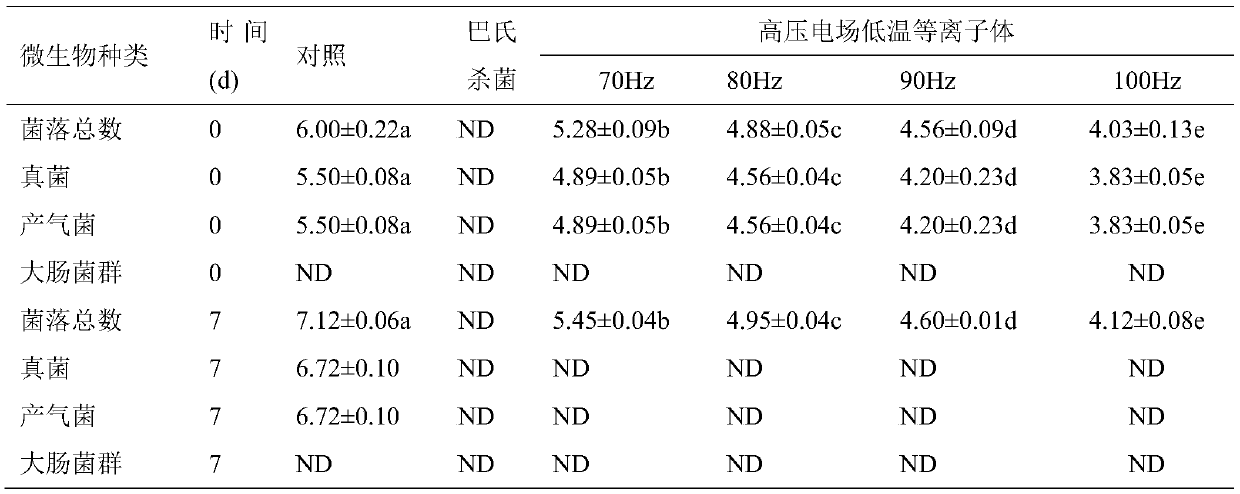

[0021] Embodiment 1 The fresh-keeping method of low-salt radish kimchi based on high-voltage electric field low-temperature plasma cold sterilization technology

[0022] (1) Preparation of product liquid packaging content: adjust the total acidity of the pickled fermentation liquid to 0.4% and the NaCl concentration to 2.5% with drinking water;

[0023] (2) Kimchi raw material fermentation: the fermented brine NaCl concentration of pickles is controlled at 4%, the fermentation temperature is controlled at 25°C in step (2), and the time is 3 days, fermented to pickle NaCl concentration at 2.5%; total acidity at 0.4%; The total number of colonies is 10 4 CFU / mL, that is, the fermentation is completed;

[0024] (3) Packaging: Add the product in (2) to the liquid packaging content of the product in (1) at a ratio of 1:1 (w / v) for packaging;

[0025] (4) Sterilization treatment: The ion plasma generating device includes a voltage regulator, a high-voltage electric field generator...

Embodiment 2

[0036] Embodiment 2 The preservation method of low-salt radish kimchi based on high-voltage electric field low-temperature plasma cold sterilization technology

[0037] (1) fermentation of kimchi raw materials: the NaCl concentration of the fermentation brine of kimchi is controlled at 6%, the fermentation temperature in step (1) is controlled at 30 ° C, and the time is 3 days, and the kimchi NaCl concentration is fermented to 3.0%; total acidity is 0.6%; The total number of colonies is 10 5 CFU / mL, that is, the fermentation is completed;

[0038] (2) Packaging: the product in (1) is packaged by MAP, and the atmosphere condition of MAP packaging is 0 2 / CO 2 / He / N 2 =30±5 / 30±5 / 10±5 / 30±5%;

[0039] (3) Sterilization treatment: The ion generating device includes a voltage regulator, a high-voltage electric field generator, an upper electrode, a lower electrode and an insulating guard plate. The MAP-packaged kimchi is placed between the upper and lower electrodes, and the upp...

Embodiment 3

[0050] Embodiment 3 Low-salt pickled cabbage preservation method based on high-voltage electric field low-temperature plasma cold sterilization technology

[0051] (1) Preparation of product liquid packaging contents: adjust the total acidity of the pickled fermentation broth to 0.6% and the NaCl concentration to 4.0% with drinking water;

[0052] (2) Fermentation of kimchi raw materials: the NaCl concentration of the fermented brine of kimchi was controlled at 8.0%, the fermentation temperature was controlled at 25°C, and the fermentation time was 7 days until the kimchi NaCl concentration was 4.0%; the total acidity was 0.6%; the total number of colonies was 10 6 CFU / mL, that is, the fermentation is completed;

[0053] (3) Packaging: add the product in (2) into the liquid packaging content of the product in (1) at a ratio of 1:1 (w / v) for packaging;

[0054] (4) Sterilization treatment: The ion generation device includes a voltage regulator, a high-voltage electric field ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com