Method of sterilizing and enzyme-eliminating for fluid food

A food and enzyme inactivation technology, applied in food preservation, food science, application, etc., can solve problems such as incomplete sterilization, easy damage to heat-sensitive ingredients, loss of umami substances, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

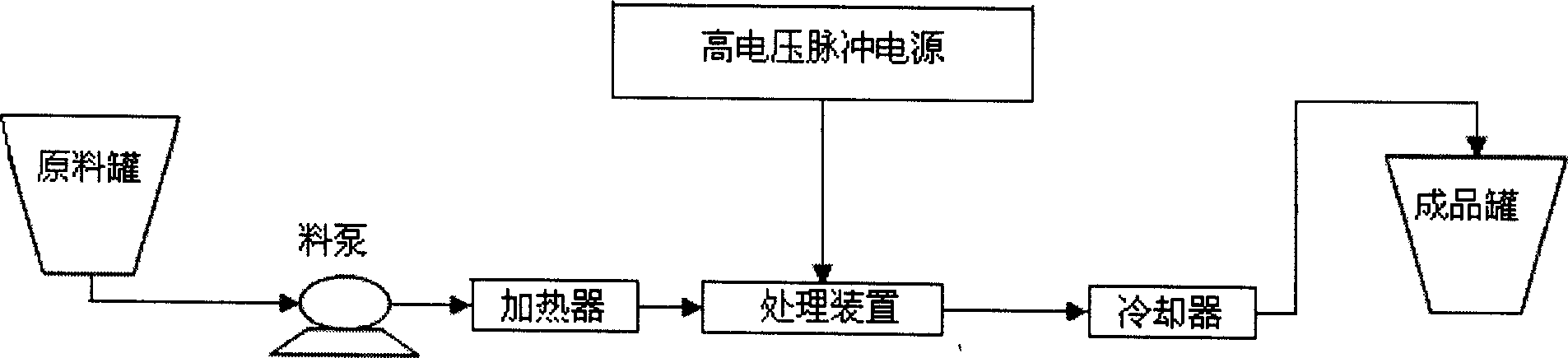

Method used

Image

Examples

Embodiment 1

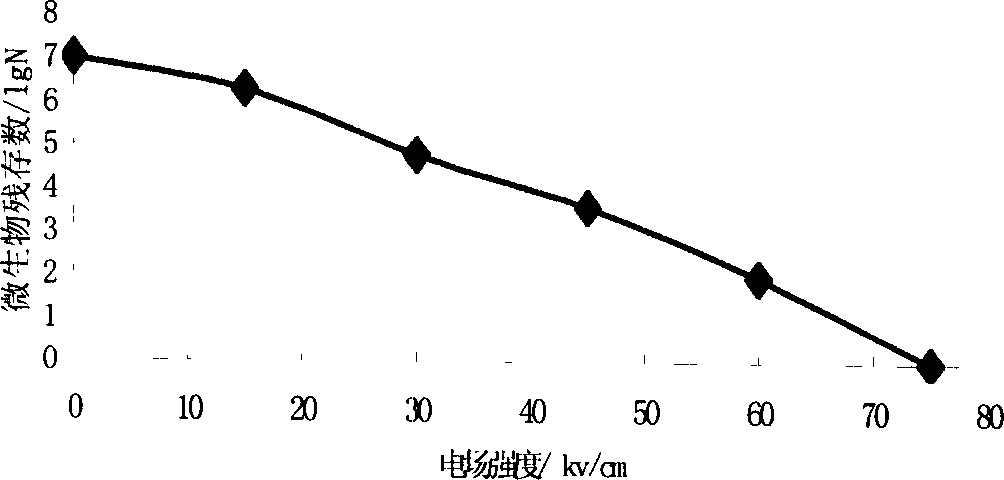

[0028] Influence of electric field strength on the sterilization effect of fresh milk:

[0029] The number of processing pulses is 6, and the initial microbial count of raw fresh milk is 1.0×10 7 cfu / ml. Under the condition of room temperature (20°C), the electric field intensity is 75kv / cm, 60kv / cm, 45kv / cm, 30kv / cm, and 15kv / cm respectively to process raw fresh milk. The relationship between the number of microbial residues in the medium and the strength of the treatment field is as follows: figure 2 shown.

[0030] from figure 2 It can be seen that as the field strength increases, the sterilization effect becomes more obvious. When the electric field intensity is lower, that is, below 30kv / cm, the bactericidal effect of the electric field on raw fresh milk is not obvious. reduced, the bactericidal effect was significantly improved. When the electric field strength reaches 75kv / cm, all the microorganisms in the milk can be killed. During the entire sterilization pro...

Embodiment 2

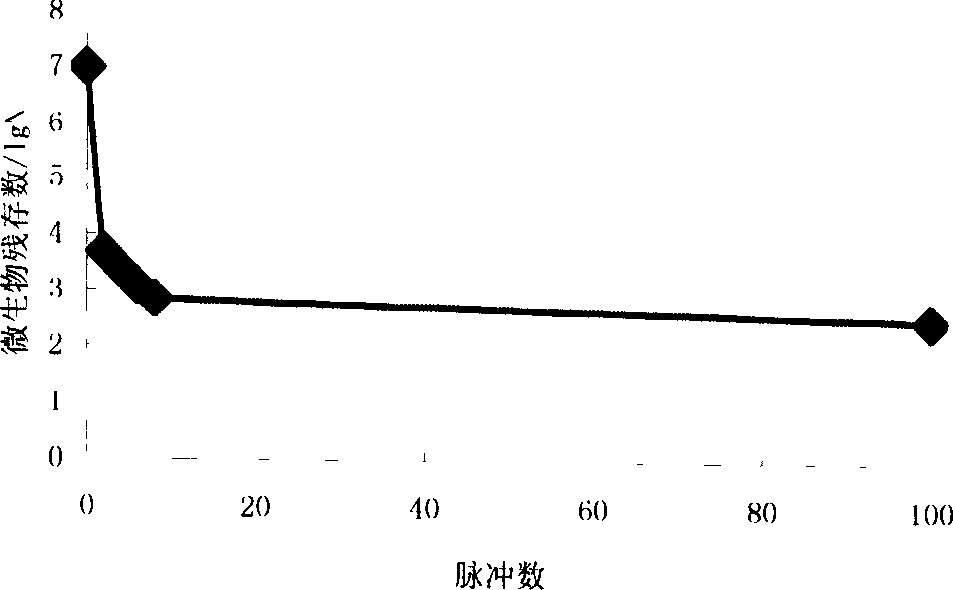

[0032] Effect of pulse number on fresh milk electric field sterilization effect

[0033] The initial microbial count of raw fresh milk is 1.0×10 7 cfu / ml. At room temperature, the electric field strength is 50kv / cm, and the number of pulses is 2, 4, 6, 8, 100 to process the raw milk, and the relationship between the number of microbial residues in the raw milk and the number of pulses is determined by the microbial plate counting method. , the result is as image 3 shown.

[0034] from image 3 It can be seen that under the same electric field strength (50kv / cm) and room temperature (20°C), the bactericidal effect of the electric field increases with the increase of the pulse number, but the curve is relatively flat. When the pulse number increases by 50 times, the number of residual bacteria only decreases. 1 order of magnitude. Therefore, it can be considered that the number of pulses has little influence on the sterilization effect of the electric field, so a smaller n...

Embodiment 3

[0036] Effect of temperature on fresh milk electric field sterilization effect

[0037] Under the conditions of electric field strength E=50kv / cm, number of pulses C=6 per treatment, and temperatures of 10°C, 15°C, 20°C, 25°C, and 30°C, high-voltage pulse electric field sterilization is performed on raw fresh milk. The total number of bacteria in raw fresh milk is 1.0×10 7 cfu / ml. The relationship between the change of the total number of bacteria in the fruit juice and the temperature after electric field treatment is as follows: Figure 4 shown

[0038] Depend on Figure 4 It can be seen that under the same electric field strength of 50kv / cm and pulse number of 6, the temperature has a greater influence on the bactericidal effect of raw milk, and the higher the temperature, the better the bactericidal effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com