Method for sterilizing liquid food by virtue of micro plasma

A micro-plasma, liquid food technology, applied in the field of ionic liquid food sterilization, can solve the problems of expensive radiation equipment, denaturation of nutrients, loss of flavor components, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

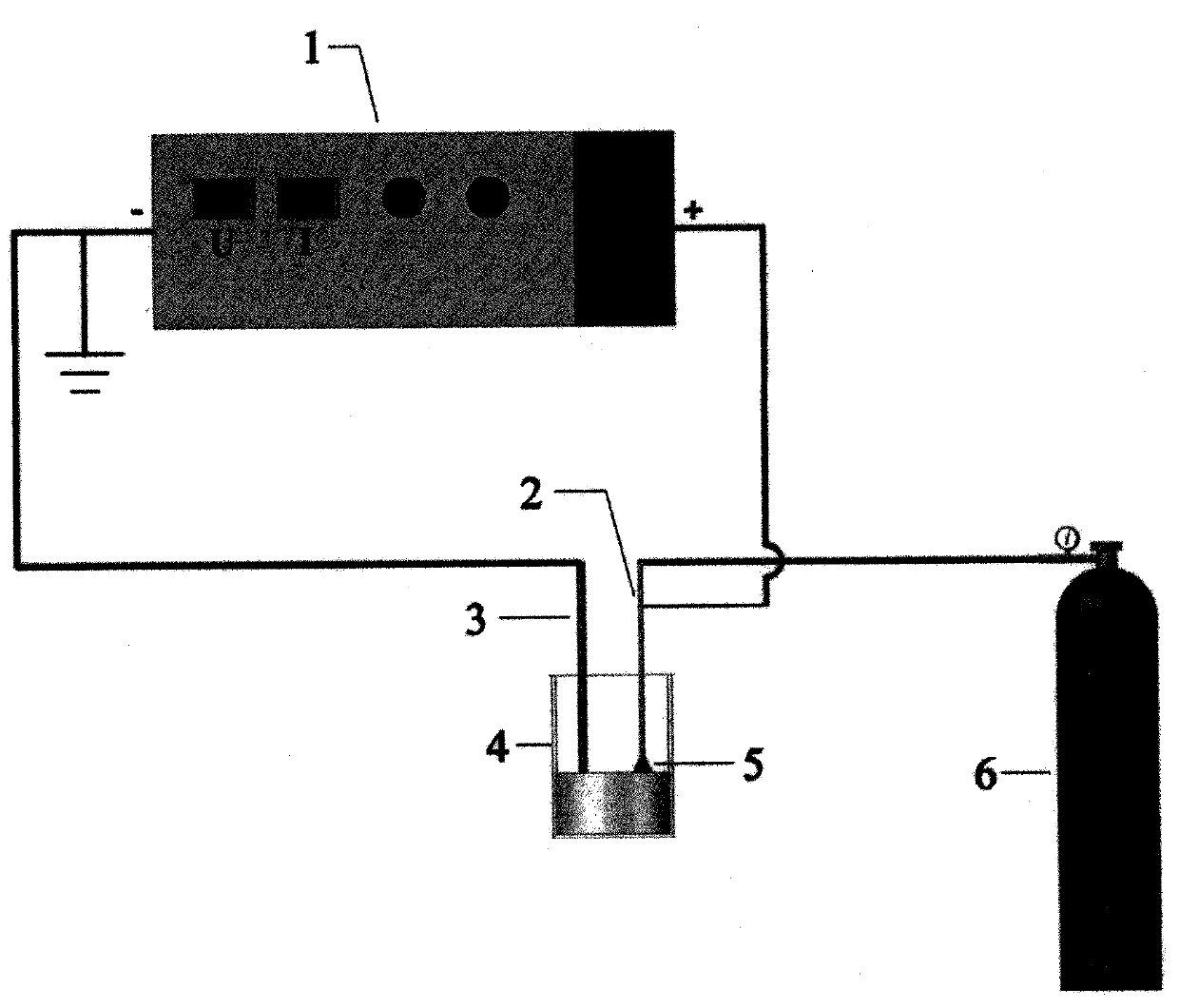

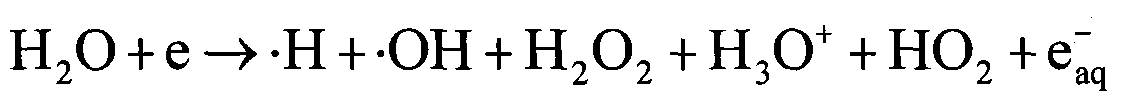

[0014] As shown in the accompanying drawing, the bactericidal test was carried out with the apple juice added with the disinfection indicator bacteria Escherichia coli (No.: ATTC25922) as the treatment object. 100mL of apple juice was introduced into the micro-plasma device. The micro-plasma device used a glass reactor with a height of 8.5 cm and an inner diameter of 5.5 cm. The main body of the anode is a stainless steel tube with a length of 8 cm and an inner diameter of 0.7 mm. Oxygen is injected into the stainless steel electrode body through the pipeline from the oxygen source to the reactor. The stainless steel electrode is placed vertically above the reaction water, and the gas outlet of the electrode is 2mm away from the water surface. The cathode is a tungsten rod with a length of 15em and a diameter of 1mm. The tungsten rod is connected to the ground terminal of the DC high voltage power supply. The two electrodes were kept at a distance of 4 cm. After starting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com