Sterilization device based on microsecond high-voltage pulse power supply

A technology of sterilization and disinfection device and high-voltage pulse power supply, which is applied in the field of high-voltage pulse power supply, can solve the problems of high cost, limited application range, switch damage, etc., and achieve the effect of high output voltage, high reliability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

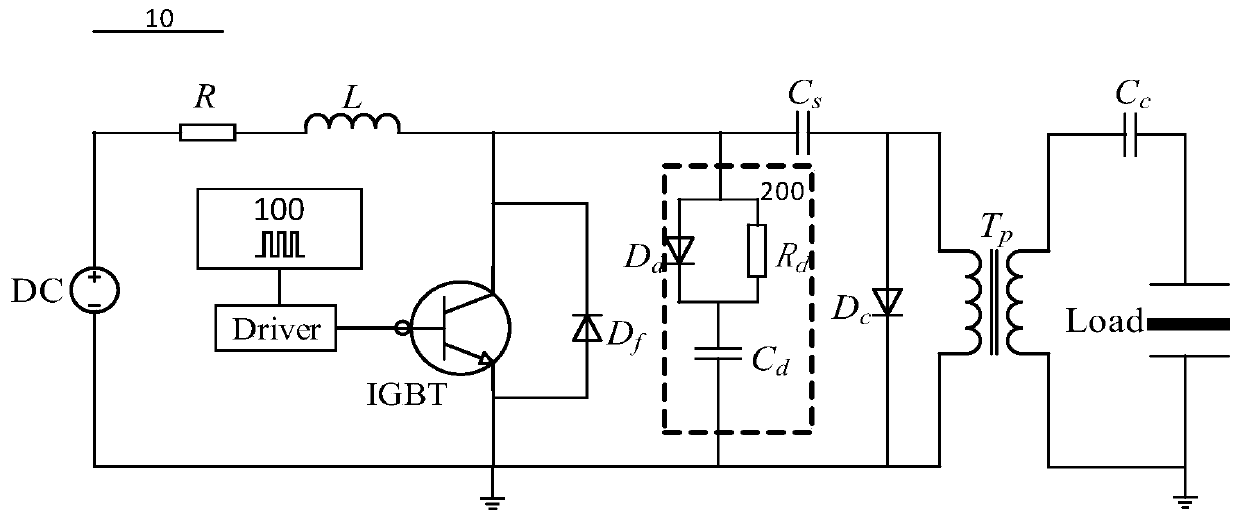

[0032]Further, in one embodiment of the present invention, microsecond high-voltage pulse power supply drives DBD for sterilization and disinfection. The pulse voltage requirement is about 30-40kV, the pulse width is at the μs level, and the repetition frequency is 1kHz. The small-scale sterilization and disinfection device The power is about several hundred watts, specifically: the pulse peak voltage is up to 50kV, the polarity is adjustable, the pulse width is 3μs to 20μs, the repetition frequency is adjustable within 1kHz, and the maximum power is 1kW. Specific examples are as follows:

[0033] High-voltage direct-current power supply DC: The selected parameters are a direct-current power supply with a rated voltage of 1000V and a rated power of 1kW.

[0034] IGBT switch: Since the price of the IGBT switch increases rapidly with the increase of the voltage level, the voltage level of the selected IGBT switch device is 1200V, which is relatively cheap and has high stability;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

| Capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com